AAAAA

Image data

Two path types enable long-sheet scanning.

Accurate Feeding for

Various Paper Types Stapled Document Detection

Multiple sensors are used to detect

various types of stapled documents,

and to immediately stop the scanner

when stapling is detected. This

minimizes damage to both the

document and the optical glass.

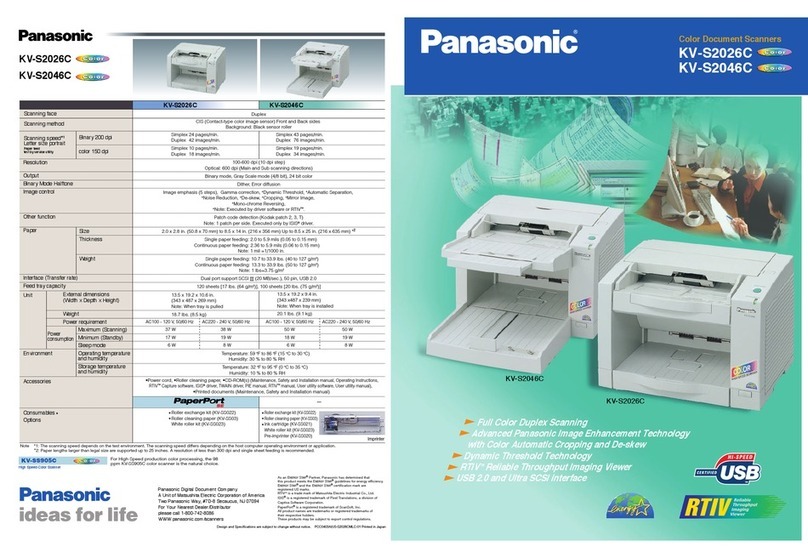

This function automatically detects when a

set of documents contains some color

sheets and some monochrome (B/W)

sheets. You can feed these together

without sorting, and the machine will

automatically compress the data efficiently

according to whether a sheet is color or

monochrome (B/W), so the electronic file

size is minimized. This is a feature

typically found only on high-end scanners.

High-Quality Image Processing

No More Need to Pre-Sort

Documents

Automatic Binary/

Color Distinction

When you scan documents of mixed size,

the documents are automatically cropped

and stored in the appropriate size. Also,

skewed documents are automatically

straightened when they are scanned.

Eliminates Post-Processing

Automatic

Crop and De-Skew

With Multi Color Dropout, you're no longer

limited to removing only reds, greens and

blues from pre-printed forms. Any color or

color range can be selected for removal

for more accurate OCR processing. And

you're not limited to only one color — you

can select up to three or even drop all

colors saving only black.

Pre-Printed Form Scanning

Multi Color Dropout

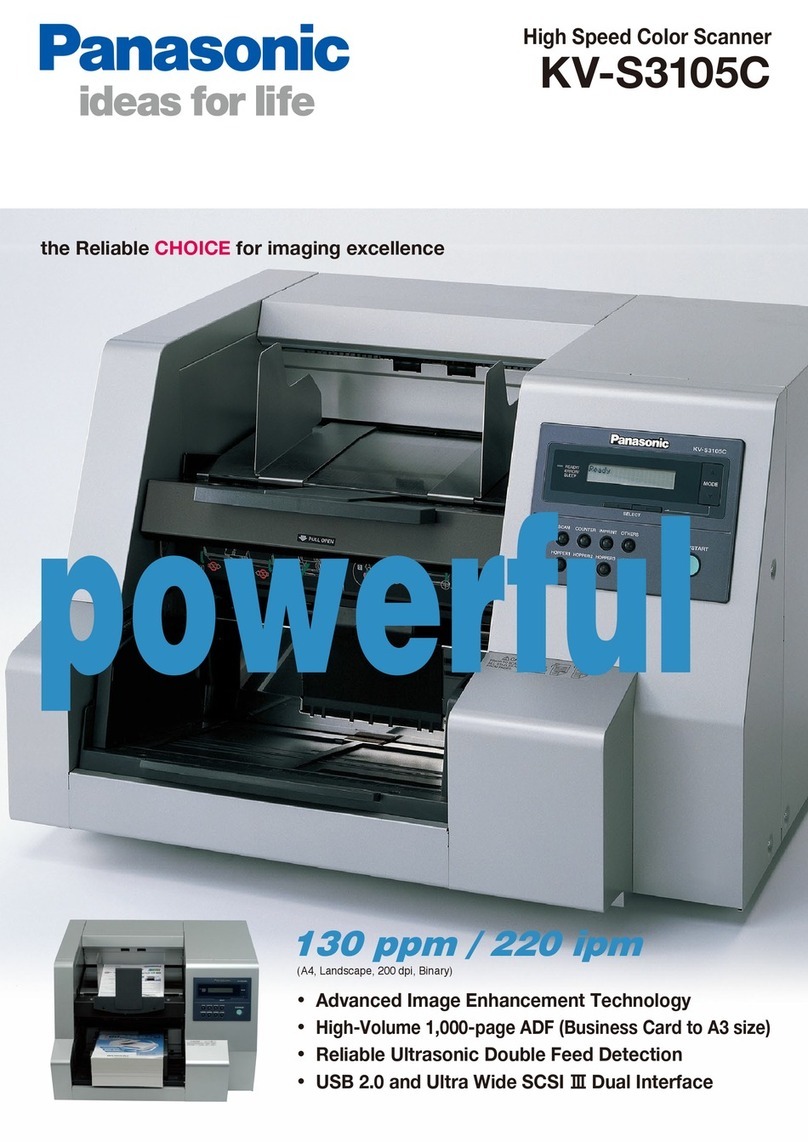

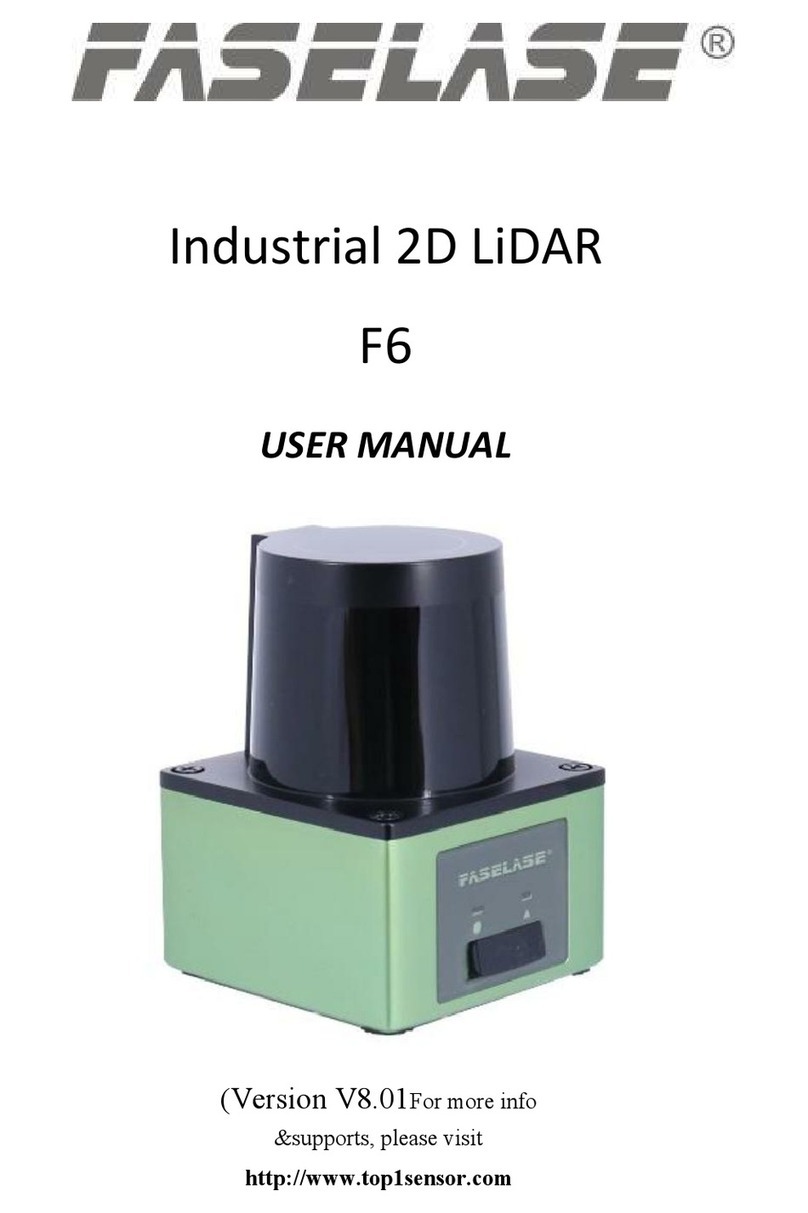

The highly reliable paper feed mechanism

quickly and stably scans long documents

too. Using the straight path, this boosts

work efficiency by smoothly scanning long

monitoring sheets, like those used for

EKG documents, and thick documents.

High-Speed Scanning of Sheets

up to 100 feet Long

Long Paper Mode

High-Reliability Scanning

Documents with different sizes and thicknesses can

all be fed together. They can be set in center, left, or

right alignment. By using left or right single-side

alignment, there is no more need to spend time

organizing documents according to their size, so

scanning is fast and easy. This function greatly

increases work efficiency.

Accurately Feeds Various Size of Documents

Mixed Document Feeding*1

Intelligent Feed Control

Multiple sensors check the paper

feed condition and automatically

adjust the roller pressure to

ensure that documents of various

thicknesses are accurately fed.

This makes it more reliable and

accurate than conventional feed

mechanism.

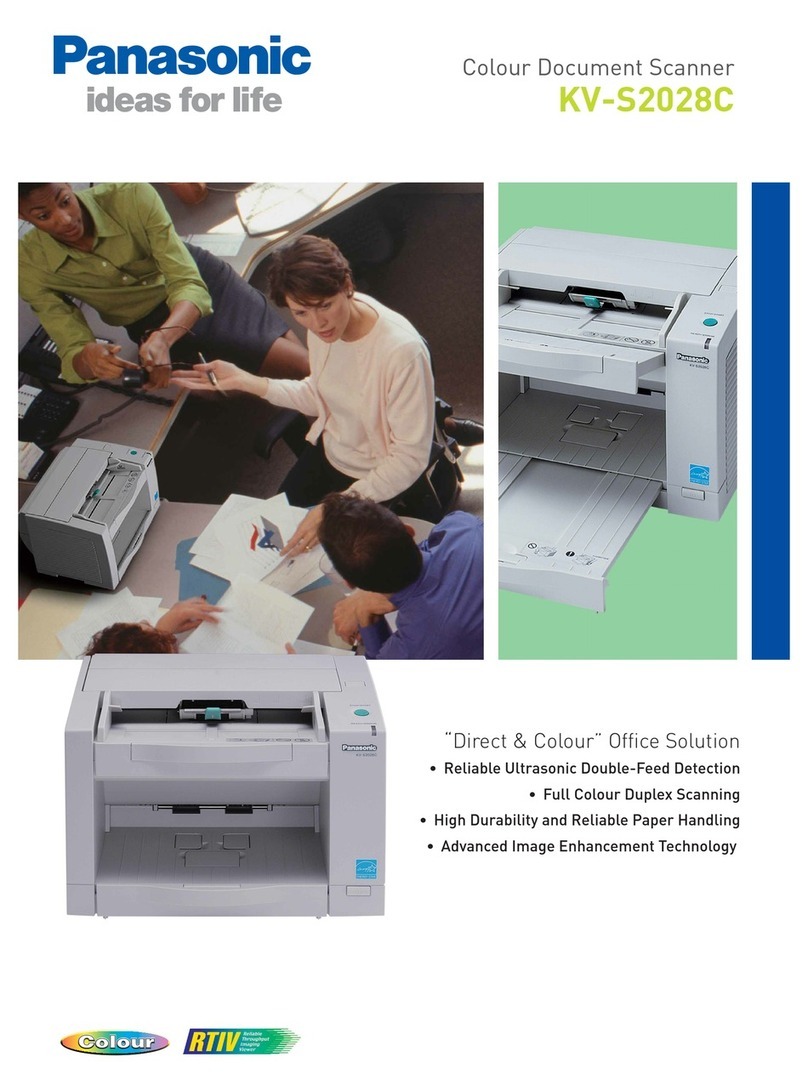

Ultrasonic Double-Feed Detection

Preventing Damage to the Scanning Glass

Smooth Feeding

Accurate Scanning

Ultrasonic sensors detect double feeds. The

KV-S4085CW/KV-S4085CL are equipped with three

ultrasonic sensors to cover a larger area of the

document, rather than the center only, for versatile

detection of small documents mixed among

regular-sized documents.

*KV-S4065CW/KV-S4065CL have one sensor.

Corner Staple Side Staple Top-center Staple

Bottom-center Staple

Image data Documents

The scanner feeds accurately, regardless of alignment. The scanner detects color or B&W. The scanner makes it easier to read text data. The scanner crops white space.

Innovative Paper Feed Mechanism

Staples are quickly detected in any location, to minimize damage to the optical glass and the document.

straight path

curved path

AAAAA

Left alignment Right alignmentCenter alignment

Setting

Position

Left alignment Right alignmentCenter alignment

Have you ever had your work interrupted by a scanner jam, and then found out that important documents

were damaged? Or after you've finished scanning, have you discovered that one or more pages were missed?

Our innovative scanner uses a reliable, industry-first paper feed mechanism to quickly detect stapled

documents and halt scanning to minimize damage to the optical glass

and the document. It also senses double-sheet feeding

to prevent misfeedings. This minimizes errors

and problems in large scanning runs. Plus, it

features full-color scanning (200 or 300 dpi) at

up to 200 ipm* with clear, high-resolution results.

In short, it gives you both efficiency and quality.

*When using the KV-S4085CW Letter, Landscape, 200/300 dpi, Binary/Color.

Setting

Position

NewSystem

*1Effective widescanning of KV-S4065CL and KV-S4085CL are Letter

size from center position.

Multiple sensors constantly check

the condition of the paper feed and

the pressure between the document

and the roller.

The sensors detect

when the paper feed is

not correct due to

insufficient pressure.

The tray is raised to

adjust the pressure and

accurately feed the

document.

Documents

Paper feed roller

Checking Adjusting

(1) (2)

Multiple

Sensors

Automatically

raised

Tray

Feeding

direction Insufficient

pressure

Checking

feed

condition

Three sensors*detect double feeding

and stop the scanner immediately.

High-performance sensors catch

even subtle changes.

Feed direction Transmitter

Small documentReceiver

天裏

地

KV-S4085CW/CL・KV-S4065CW/CL レターサイズ 中面 CMYK