QUICK INSTRUCTION MANUAL

Non-Contact Safety Door Switch

SG-P Series

CMJE-SGP No.0077-95V

Thank you very much for purchasing Panasonic products.

Please read this Instruction Manual carefully and thoroughly for the correct

and optimum use of this product. Kindly keep this manual in a convenient

place for quick reference.

This document provides a brief summary of mounting, wiring, and other related information.

When using the product, refer to the SG-P Series Instruction Manual in addition to this manual.

1SAFETY CAUTIONS Always observe

This section explains important rules that must be observed to prevent human injury and property damage.

Ŷ

7KHKD]DUGVWKDWPD\RFFXULIWKHSURGXFWLVXVHGLQFRUUHFWO\DUHGHVFULEHGDQGFODVVL¿HGE\OHYHORIKDUP

WARNING Risk of death or serious injury.

CAUTION

Risk of minor injury or property damage.

WARNING

Machine designer, installer, employer and operator

• The machine designer, installer, employer and operator are solely responsible to

ensure that all applicable legal requirements relating to the installation and the use

LQDQ\DSSOLFDWLRQDUHVDWLV¿HGDQGDOOLQVWUXFWLRQVIRULQVWDOODWLRQDQGPDLQWHQDQFH

contained in the instruction manual are followed.

• Whether this device functions as intended to and systems including this device

comply with safety regulations depends on the appropriateness of the application,

installation, maintenance and operation. The machine designer, installer, employer

and operator are solely responsible for these items.

Engineer

• The engineer would be a person who is appropriately educated, has widespread

knowledge and experience, and can solve various problems which may arise

during work, such as a machine designer, installer or employer etc.

Operator

• The operator should read this instruction manual thoroughly, understand its con-

tents, and perform operations following the procedures described in this manual

for the correct operation of this device.

• In case this device does not perform properly, the operator should report this to the

person in charge and stop the machine operation immediately. The machine must

QRWEHRSHUDWHGXQWLOFRUUHFWSHUIRUPDQFHRIWKLVGHYLFHKDVEHHQFRQ¿UPHG

Operating environment

• Do not use this device outdoors.

• Do not use this device in an explosion-proof area.

• Do not install this device in the following places:

1) Areas with high humidity where condensation is likely to occur

2) Areas exposed to corrosive or explosive gases

3) Areas exposed to contact with water

4) Areas exposed to too much steam or dust

• Do not use this device near equipment that emits strong electromagnetic waves.

Machine in which this device is installed

• Do not install this device with a machine whose operation cannot be stopped

immediately in the middle of an operation cycle by an emergency stop equipment.

• This device starts the performance after approximately 2 seconds from the power

ON.Have the control system started to function with this timing.

• Do not use the device improperly or do not invalidate the settings after installing

the device. Otherwise, the safety functions of the apparatus which uses this device

may not work properly, resulting in death or serious injury.

• Do not install the switch body of this device on a movable door.

• When installing this device, always consider the time required to ensure a safe state

and provide a distance equal to or longer than the correctly calculated safety distance

between the apparatus which uses this device and the dangerous parts of the machine.

• &RQ¿UPWKDWWKHUHVSRQVHWLPHRIWKHHQWLUHPDFKLQHLVOHVVWKDQWKHFDOFXODWHG

value before designing the equipment.

Wiring

• Be sure to carry out the wiring in the power supply OFF condition.

• All electrical wiring should conform to the regional electrical regulations and laws.

The wiring should be done by engineer(s) having the special electrical knowledge.

• After completing wiring, check the wiring state before supplying power.

• Do not wire the controller in parallel with a high-voltage line or power line or use the

same conduit as these lines. Doing so may result in malfunctioning due to induction.

• Do not apply stress such as excessive bending or pulling to a cable or the

extracted part of a cable. In particular, when the temperature is low, cable materials

harden, and when the temperature is high, the materials soften, and so take care

that cables may break if they are subject to stress such as bending or pulling when

the temperature is low or high.

• When connecting multiple switch bodies, arrange their layout so that the total cable

length is 100 m or less. Furthermore, determine the distance between the switch

bodies so that the maximum cable length between them is 20 m or less.

•

When using only one switch body, arrange its layout so that the maximum cable length is 20 m or less.

• When extending the cable of this device, use 0.3 mm2or larger cable.

•

When wiring, make sure that liquid such as water or oil does not intrude from the end of the cable.

Maintenance

• When replacement parts are required, always use only genuine supplied

replacement parts. Using substitute parts from another manufacturer may cause

the device not to detect objects, resulting in death or serious injury.

•

The periodical inspection of this device must be performed by an engineer having the special knowledge.

• After maintenance or adjustment, and before starting operation, test this device

IROORZLQJWKHSURFHGXUHVSHFL¿HGLQ³ 8Maintenance”.

• Clean this device with a clean cloth. Do not use any volatile chemicals.

Others

• 1HYHUPRGLI\WKLVGHYLFH0RGL¿FDWLRQPD\FDXVHWKHGHYLFHQRWWRGHWHFWREMHFWV

resulting in death or serious injury.

CAUTION

6SHFL¿FDWLRQV

• This product has been developed / produced for industrial use only.

•

'RQRWXVHWKLVSURGXFWRXWVLGHWKHUDQJHRIWKHVSHFL¿FDWLRQV5LVNRIDQDFFLGHQWDQGSURGXFWGDPDJH

• There is also a risk of a noticeable reduction of service life.

• Use this device by installing suitable protection equipment as a countermeasure

for failure, damage, or malfunction of this device.

• Before using this device, check whether the device performs properly with the

IXQFWLRQVDQGFDSDELOLWLHVDVSHUWKHGHVLJQVSHFL¿FDWLRQV

• Note that this device may be damaged if it is subject to a strong shock (if it is

GURSSHGRQWRWKHÀRRUIRUH[DPSOH

• Do not use the device near an apparatus that generates magnetic fields.

2WKHUZLVHWKHRSHUDWLQJGLVWDQFHPD\EHDႇHFWHG

•

Do not apply an excessive shock to the safety switch when opening or closing the door.

• Use of this device under the following conditions or environments is not presupposed.

Please consult us if there is no other choice but to use this device in such an environment.

1)

Operating this device under conditions or environments not described in this manual.

2)

8VLQJWKLVGHYLFHLQWKHIROORZLQJ¿HOGVQXFOHDUSRZHUFRQWUROUDLOURDGDLUFUDIW

auto mobiles, combustion facilities, medical systems, aerospace development, etc.

Power supply

• 9HULI\WKDWWKHVXSSO\YROWDJHÀXFWXDWLRQVDUHZLWKLQWKHUDWLQJ

• When using a commercial switching regulator for the power supply, be sure to

ground the frame ground (F.G.) terminal of the power supply.

•

When using the device, avoid the transient state that occurs when the power supply is turned ON.

•

When connecting multiple devices together, connect all the devices to the same power supply.

Other precautions

• Never attempt to disassemble, repair, or modify the product.

• When the product becomes unusable or unneeded, dispose of the product

properly as industrial waste by abiding by the applicable law in the country.

2CONTENTS OF PACKAGE

Device : Switch body, Actuator 1 unit

Quick Instruction Manual (Japanese / English, Chinese)

1 PC each

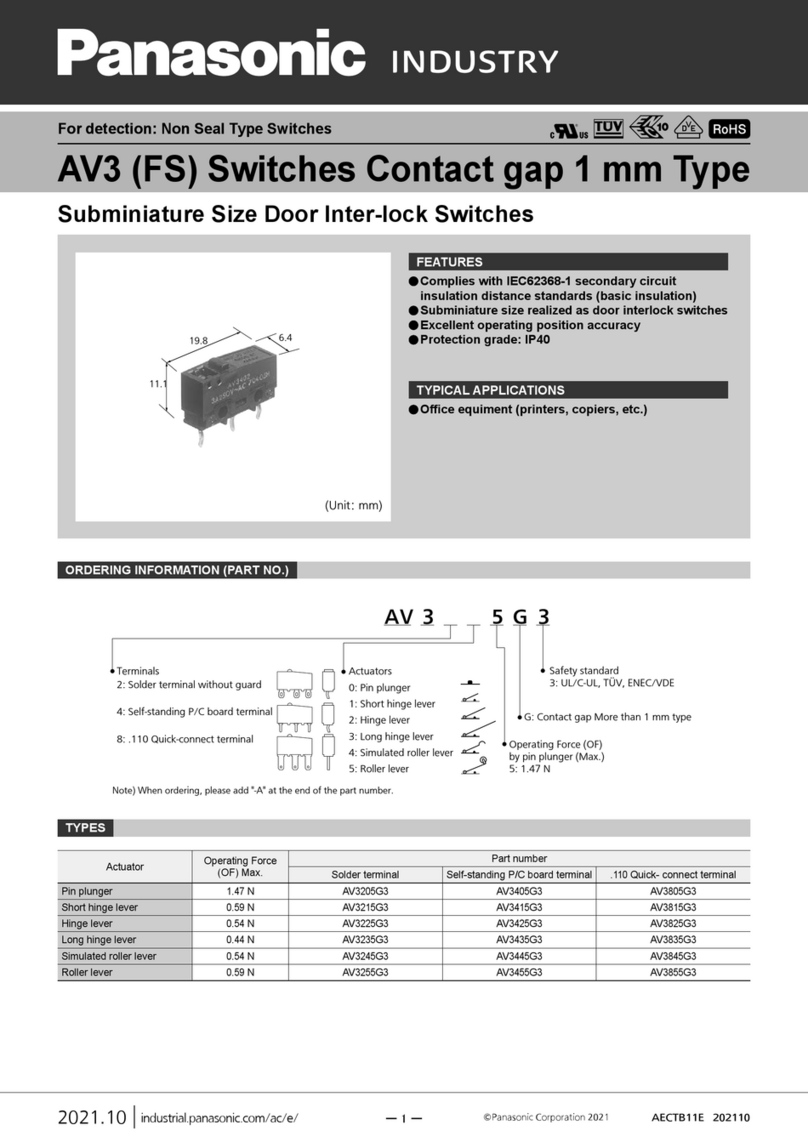

3PRODUCT CONFIGURATION

Ɣ 7KLVGHYLFHLVFRQ¿JXUHGRQDVZLWFKERG\DQGDQDFWXDWRU

ƔThis device is available as the 6*3ƑƑ0 standard units and as the 6*3ƑƑ6

sub units. For one 6*3ƑƑ0 standard unit, up to a maximum of 29 6*3ƑƑ6

sub units can be operated by connecting them in a cascade connection.

Ɣ )RUGHWDLOVRQ0RGHO1RUHIHUWR³

10

Model No.”.

Possible to connect a maximum of 29 units.

Safety

controller

Power supply unit

Standard

6*3ƑƑ-M

Sub 6*3ƑƑ-S

Actuator

Switch body

Sub 6*3ƑƑ-S

Sub 6*3ƑƑ-S

ƔNote that the 6*3ƑƑ6 sub unit cannot be used alone. When using a single

device, use the 6*3ƑƑ0 standard unit. When connecting multiple devices

together, use the 6*3ƑƑ6 sub unitfor the second unit onwards.

ƔThe 6*3ƑƑ0 standard unit can be connected with all 6*3ƑƑ6 sub units.

Ɣ

Be sure to use this device together with a safety device such as a safety controller.

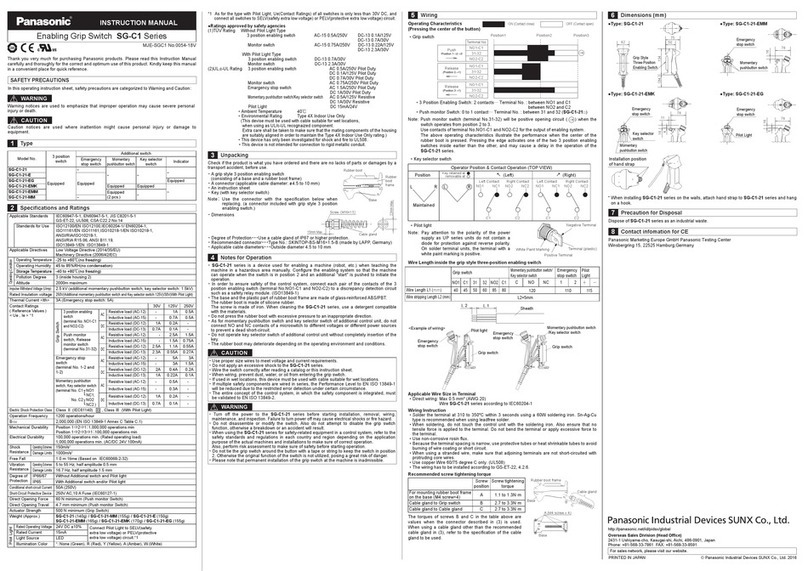

4NAME AND FUNCTION OF THE DEVICE

Ɣ

Compact type

Name Function

Indicator

Lights green

When the actuator is detected

Lights red When the actuator is not detected

Blinks red •Lockout state, error occurrence

•

When the teaching sequence was incorrect (only when using high code models)

Blinks green

•

When multiple units are connected, the actuator is not detected by other switch bodies.

•

When multiple units are connected, an error has occurred in other switch bodies.

Lights yellow (Green, red,

simultaneous lighting)

After the power ON, self-diagnosis

Alternately blinking red and yellow

(lights red and blinks green)

When an actuator not paired is detected (only when using high code models)

Actuator detection surface

When the actuator is brought near to the surface, the switch body detects the actuator.

Switch body detection surface

When the actuator is brought near to the switch body, the switch body detects the actuator.

Switch body detection surface

<Actuator><Switch body>

Indicator Actuator detection surface

Indicator

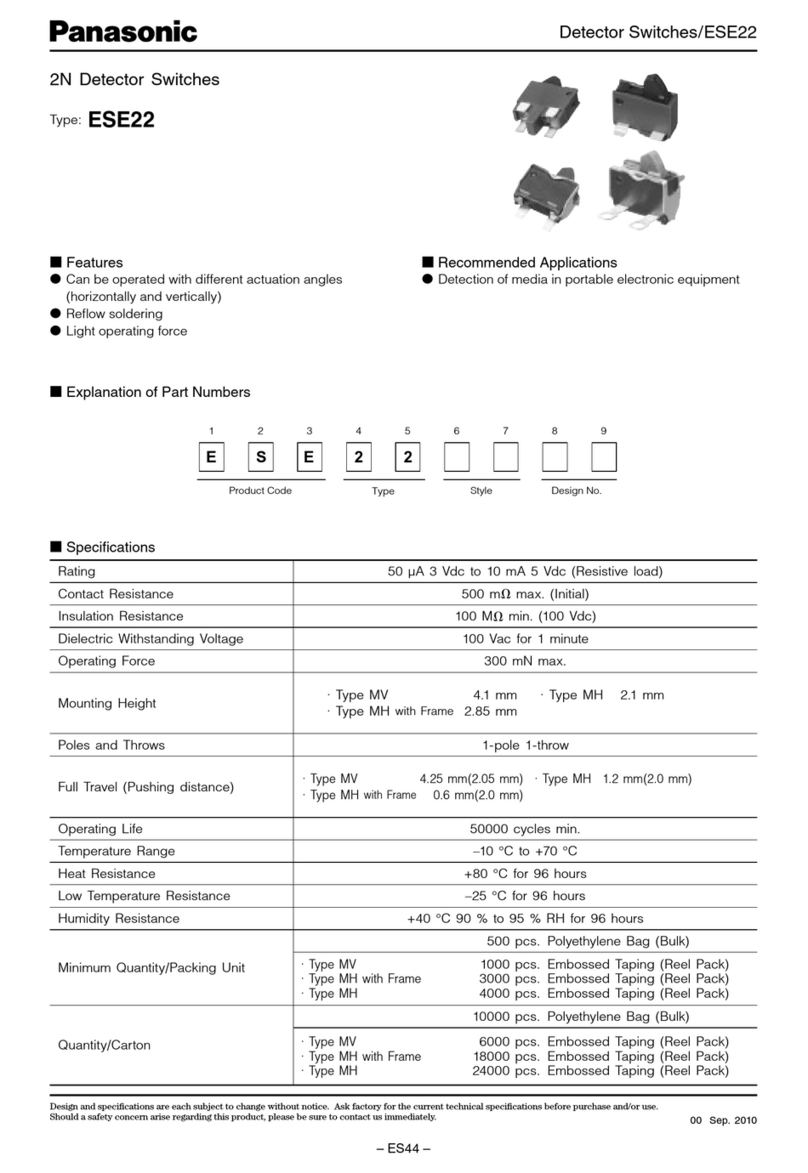

ƔVisible type

Name Function

Indicator

Lights green When the actuator is detected

Lights red When the actuator is not detected

Blinks red •Lockout state, error occurrence

•

When the teaching sequence was incorrect (only when using high code models)

Blinks green •

When multiple units are connected, the actuator is not detected by other switch bodies.

•

When multiple units are connected, an error has occurred in other switch bodies.

Lights yellow (Green, red,

simultaneous lighting)(Note)

After the power ON, self-diagnosis

Alternately blinking red and yellow

(lights red and blinks green)(Note)

When an actuator not paired is detected (only when using high code models)

Actuator detection surface

When the actuator is brought near to the surface, the switch body detects the actuator.

Switch body detection surface

When the actuator is brought near to the switch body, the switch body detects the actuator.

<Switch body>

Indicator

Indicator

<Actuator>

Transmission part

Switch body

detection surface

Actuator detection surface

Note:

When check the LED light transmitted to the actuator, depending on the angle, yellow lights may separated into green and red.