INSTRUCTIONS CM385E

For Technical Support: www.panduit.com/resources/install_maintain.asp

Page 10 of 12

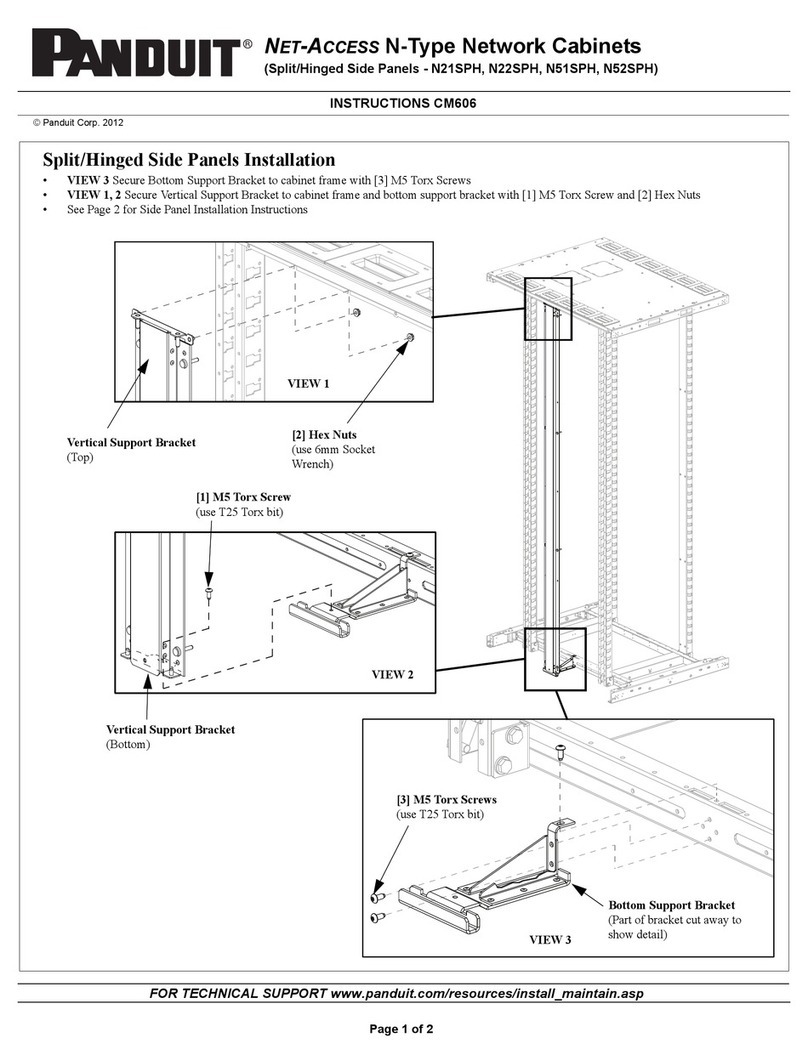

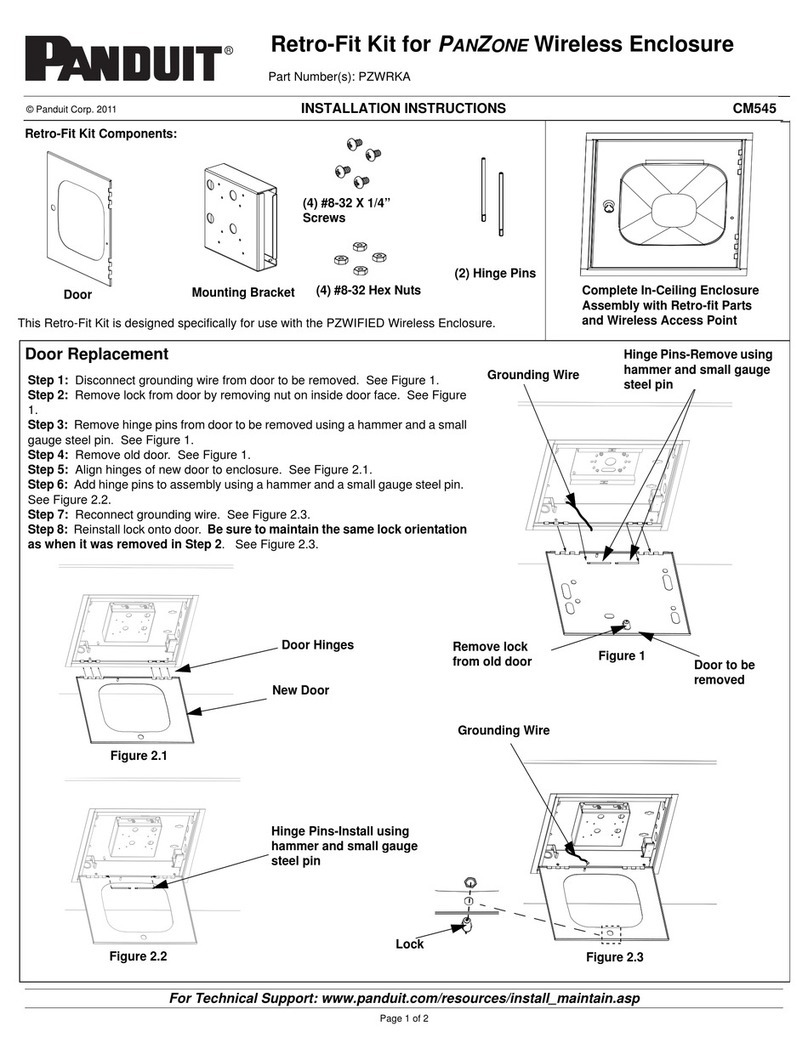

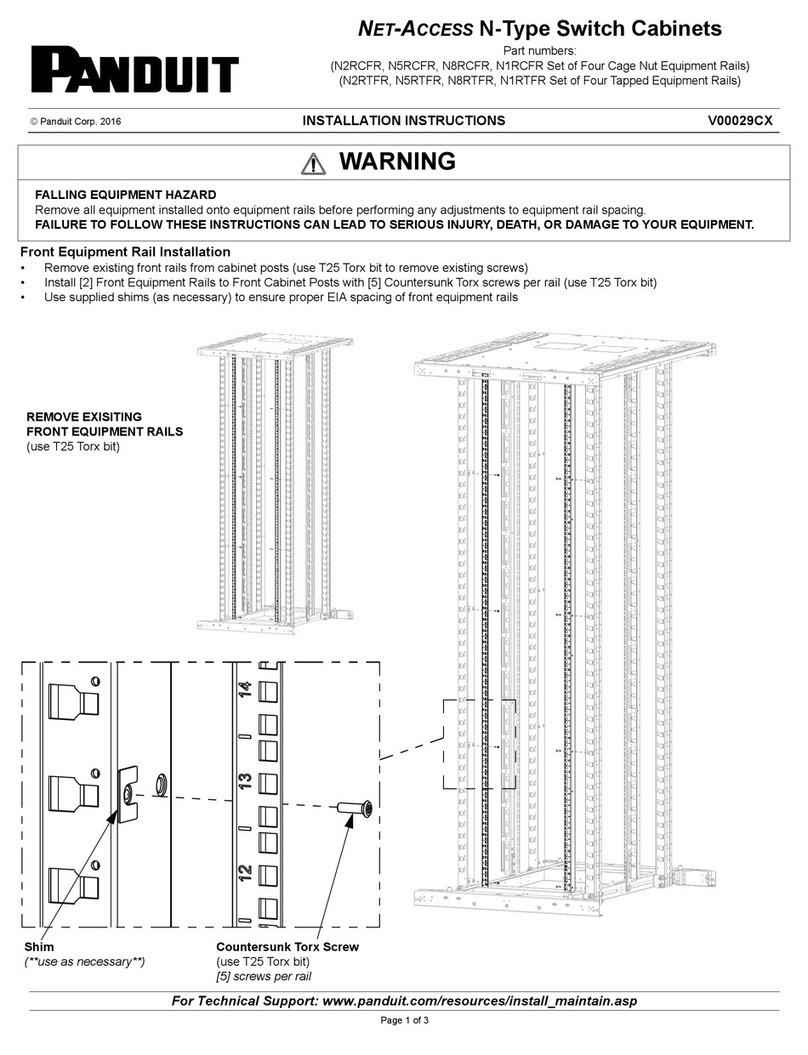

Split Door and Side Panel Installation

Lift split door and align fixed hinge pin with the bushing in the bottom

door shoe extension. Swing door up and pull down the lever of the

spring loaded hinge pin and align pin with the bushing in top cap

extension. Release lever when aligned. Verify spring loaded hinge pin

is fully engaged into bushing before proceeding.

Reverse steps to remove door.

Split Door Installation

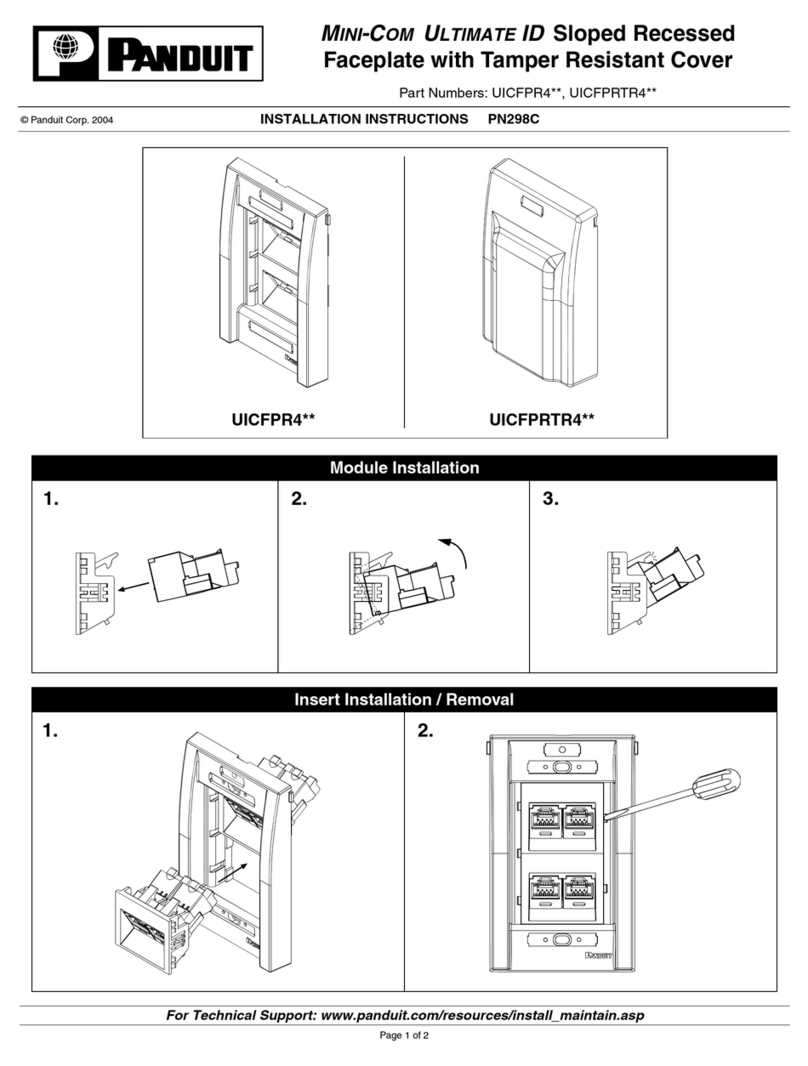

Side Panel Installation

Pull down the lever of the top spring loaded hinge pin and lock into

position. Lift side panel and align bottom pin with the hinge point in the

lower horizontal support. Swing door up and align pin with the hinge

point in top cap extension. Release locked hinge pin lever. Pull

and lock remaining spring loaded hinge pins and move side panel into

position. Release levers when aligned. Reverse steps to remove side

panels.

Spring Loaded

Fixed Hinge Pin

Hinge Pin

Top Spring

Loaded Hinge Pin

Bottom Spring

Loaded Hinge Pin

Hinge Pin

Unlocked Position

Hinge Pin

Locked Position

Adjustment of Side Panel

Reposition

Bottom Side

Extension as

necessary

Adjust side panels by loosening the (2) hex head screws securing

the bottom side extension to the cabinet frame and the (1) hex head

screw securing the extension to the door shoe extender as shown.

Reposition the bottom side extension and horizontal supports as

necessary. Tighten the (3) hex head screws.

Loosen these

screws

Loosen this

screw

Reposition

Horizontal

Support as

necessary

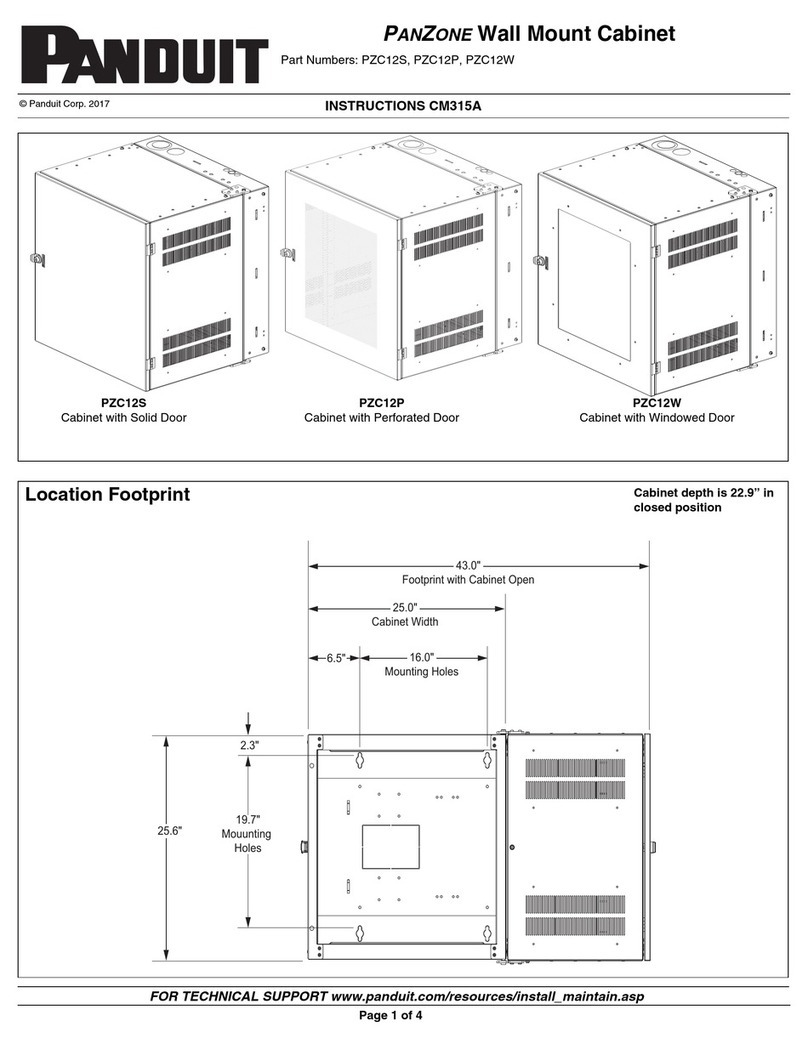

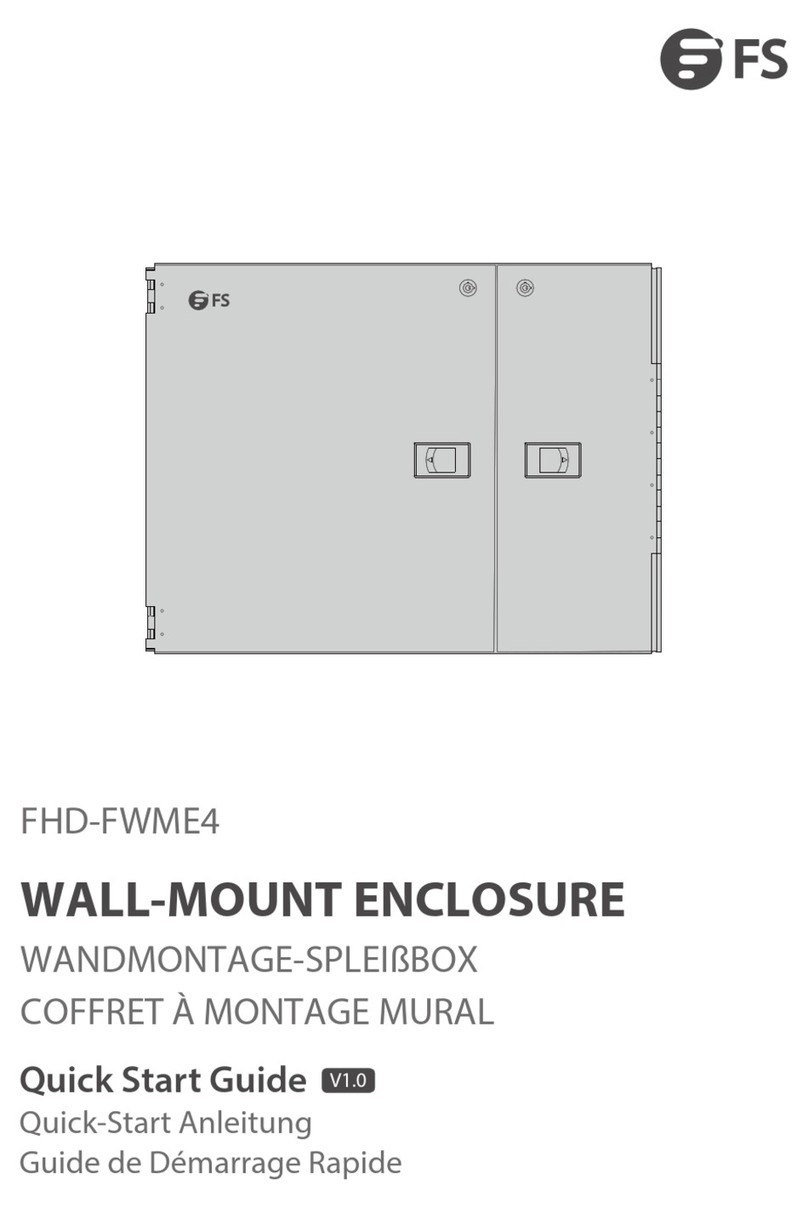

Install four (4) spring clips per side of cabinet by first removing paint

masking from area as shown. Slide spring clip in place until it clips

into pilot hole. The spring clips bond the side panel to the cabinet

frame.

Side Panel Spring Clip Installation

Spring Clip

Locations

Remove masking

from this area

Install spring clip