INSTALLATION INSTRUCTIONS

PELICAN POOL HOIST

Earthing: As per AS3000 of

the wiring rules standards

– “In certain circumstances”

it may be necessary to

have all conductive metal

objects equally potentially

bonded (earthed), this

includes Pool Hoists.

We recommend you seek

the advice and opinion

of a qualied electrician.

TOOLS REQUIRED

• Hammer Drill

• 16mm masonry bit

• Hole Cleaning Pump

• Hole Cleaning Brush

• Cartridge gun – for adhesive

• Adhesive (included)

• Acetone

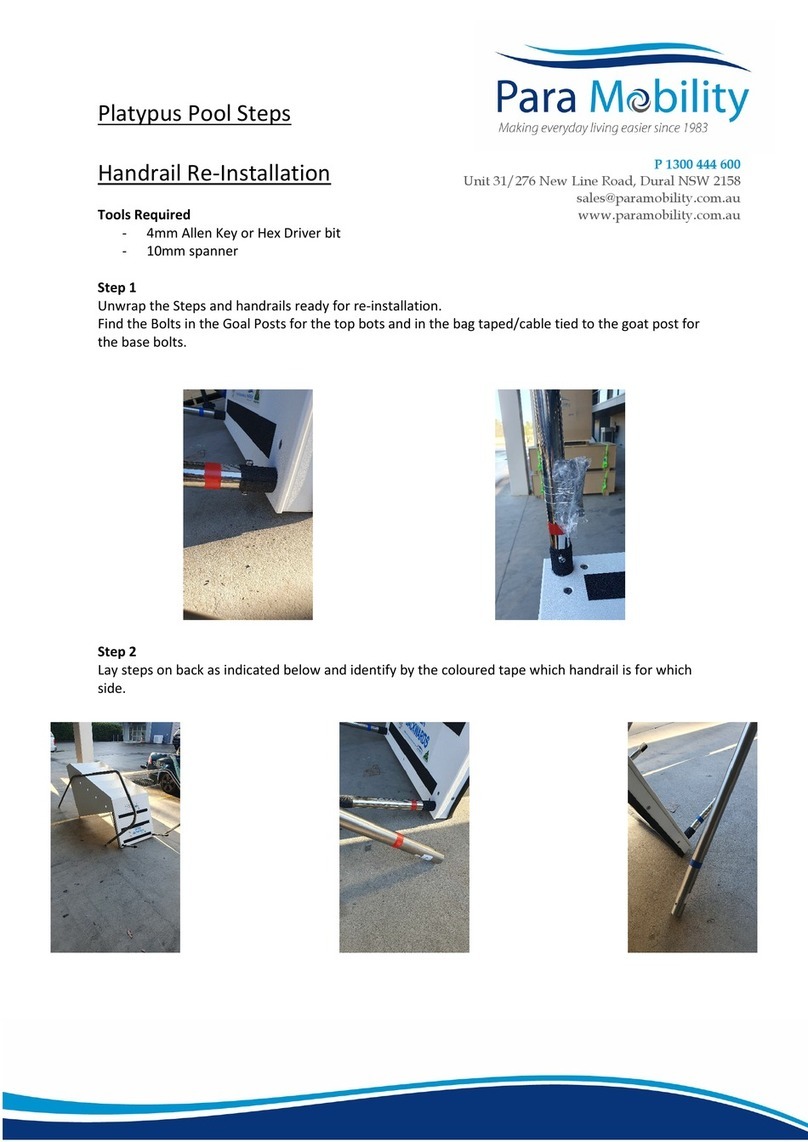

1. To safely install the Pelican Pool Hoist you will need a solid

concrete pad to anchor it to. We recommend that approximately

1/3 of cubic metres of concrete is used when pouring your pad.

This can be made up as a logical size, for example: 1000 x 1000 x

300 or 650 x 650 x 650. The ideal location is placed up against the

pool edge. It’s highly recommended to use a minimum of

20MPa concrete strength.

2. Place hoist in position, ideally around 100 to 500mm from edge

of pool (can be further but check that lifting arm will reach into pool

far enough to lower person into water). Check for obstructions when

arm of hoist is rotated. Use the hoist base as a template.

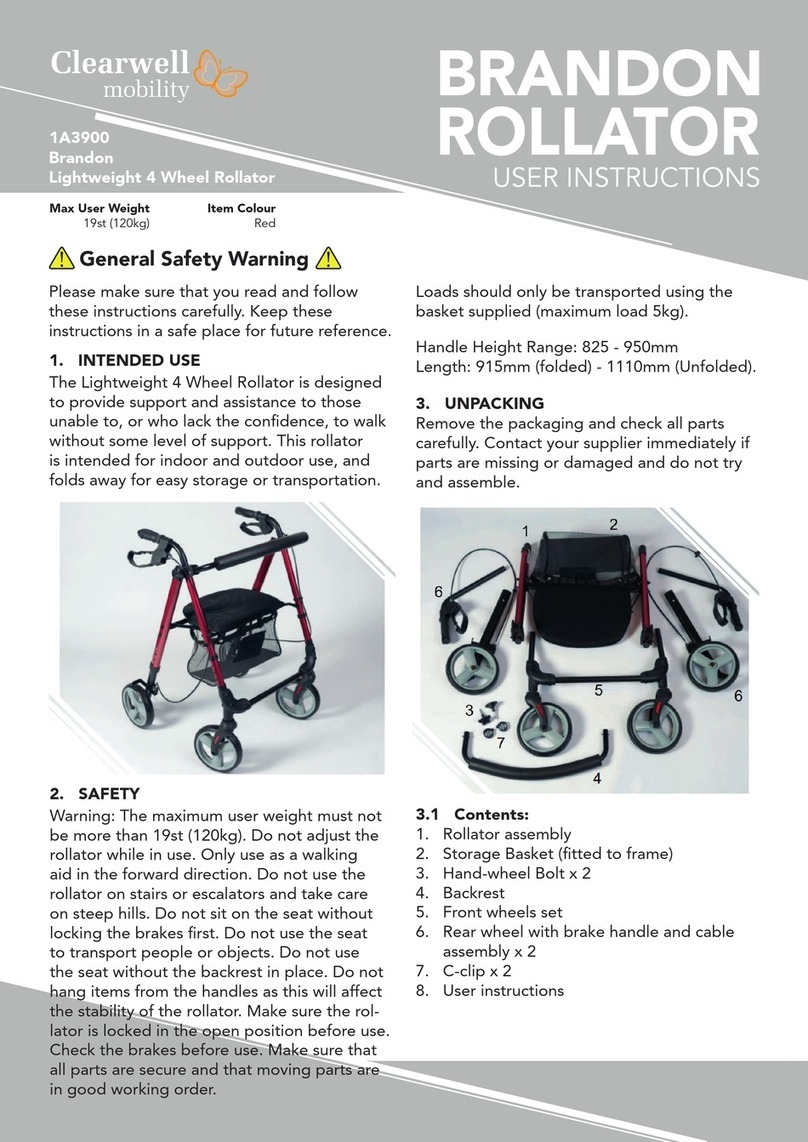

3. NB Anchors must be set into the concrete NOT into the tile bed

or pavers. If there are pavers surrounding the pool a concrete

pad must be laid – contact Para Mobility for instructions.

4. Drill 16mm diameter hole to a minimum of 100mm into concrete

substrate. (Example: 100mm below any tile bed).

5. Remove dust and debris by brushing and blowing 3 times each

(If hole is wet or ooded, remove water with wet/dry vacuum). Hole

may be damp but must not be ooded.

6. Prepare all holes and socket studs before continuing onto next

step.

7. Screw mixing nozzle onto Adhesive cartridge (supplied) and

dispense 2-3 trigger pulls of adhesive to waste until colour is grey

with no streaks.

8. Insert tip of nozzle to bottom of hole and dispense adhesive.

9. Fill hole to about 2/3 full.

10. Insert threaded stud socket, with M12 threaded socket on top, with

a rotating motion to release trapped air. Finish the top of the M12

threaded socket ush with nished oor, making sure that there is no

adhesive in the threaded socket.

11. Wait until adhesive has fully cured before loading.

12. Clean up with acetone.