Kingfisher Pool Hoist

Maintenance Schedule and Service Guidelines

The Kingfisher Pool Hoist has been manufactured in Australia and built to Australian Standards. It is

important to regularly check over your pool hoist and associated products from Para Mobility on a

regular basis.

The Kingfisher Pool Hoist is manufactured from stainless steel. Stainless steel is a corrosion resistant alloy

however, it may display rusting characteristics under certain conditions such as in plant rooms or if the

hoist is used in an indoor environment.

Following are some guidelines to assist you in developing a maintenance schedule for your hoist.

•Routinely wipe down all surfaces of the hoist, using un-chlorinated water. This will minimise the

potential build-up of corrosion or rust like symptoms (otherwise known as Tea Staining).

•In the event the equipment displays stubborn stains or heavy deposit build up, specialised

cleaning materials are needed to remove foreign substances to restore the original finish.

•Always use the supplied cover when not in use.

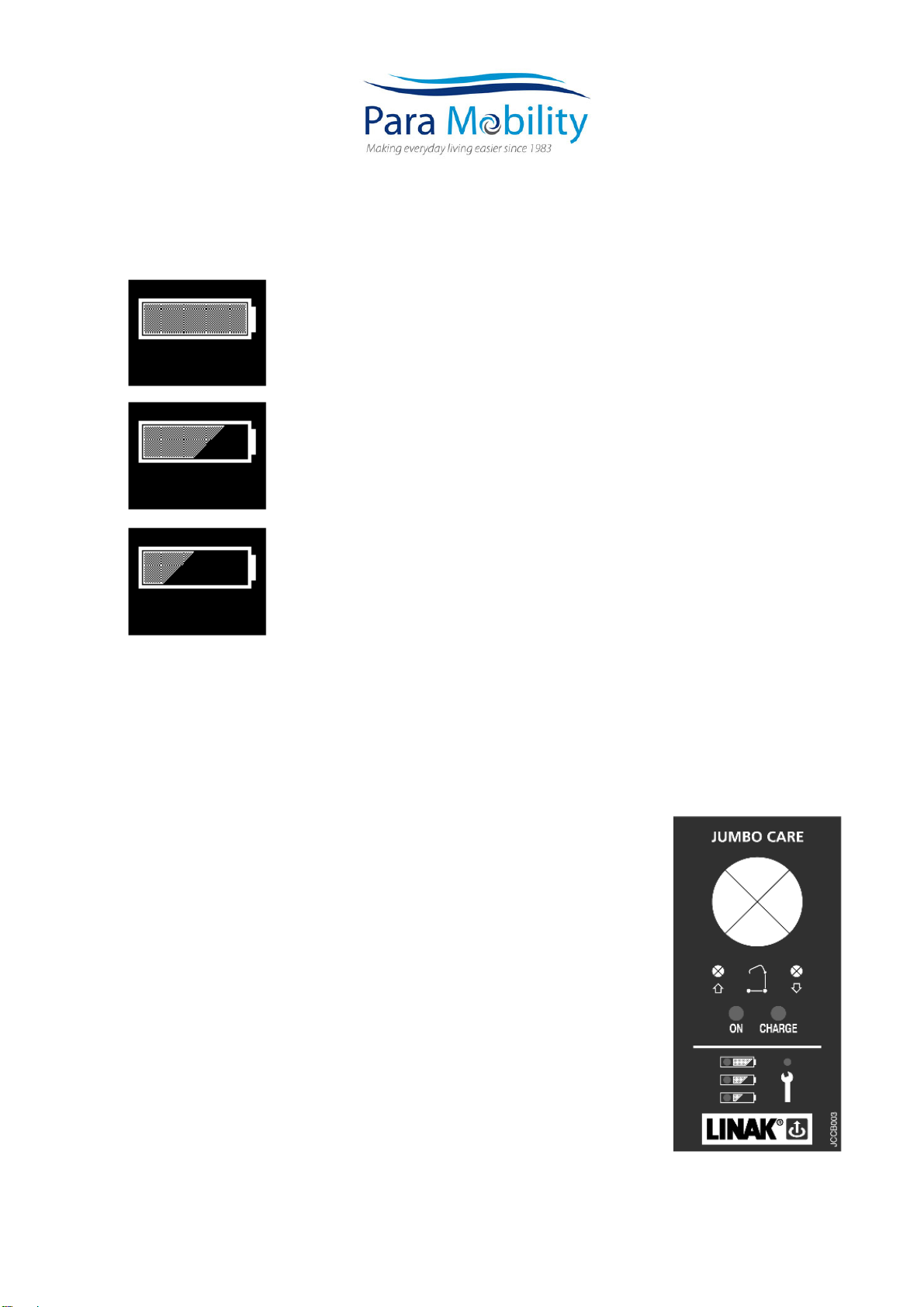

Hand Control

The Hand control is a floating hand

control. Never take the hand control out

of the control box at the bottom of the

hoist unless instructed by Para Mobility or

your distributor. Check the hand control

by regularly pressing the button in the up

and down motion and before a lift to

ensure it is working correctly. Dropping

the hand control on the ground, could

damage the internal workings, please

take care at all times.

Battery and Control Box

Pool environments can be harsh, and your battery and control box needs to be protected from the

elements and chlorine products. Ensure the cover remains on the control box and battery unless

changing the battery. Check that the battery and control box terminals have a small dab of light

grease to ensure contact is being made. A regular check of these terminals is important to ensure

every lift is successful. If any corrosion builds up on the terminals a light rub with a stainless steel pad will

remove it easily.

Actuator

The actuator lifts the main arm of the hoist. The hoist must never be rotated by pushing on the actuator,

this will damage the lifting mechanisms. Check to ensure it remains plugged into the bottom of the

control box. It must never be removed from the control box unless instructed by Para Mobility or your

distributor. When storing you pool hoist, DO NOT store it in a plant room where the hoist is exposed to

harsh chemicals, these chemicals could damage some of the inner working of the hoist. The arm of the

hoist must be kept down when not in use to minimise chemical build up on the actuator.

Safe Working Load sticker

This sticker must remain on the hoist at all times. This is the weight the hoist has been tested to lift. If this

needs replacing contact Para Mobility or your distributor.

Actuator

Floating hand control

and holder

Control Box & Battery