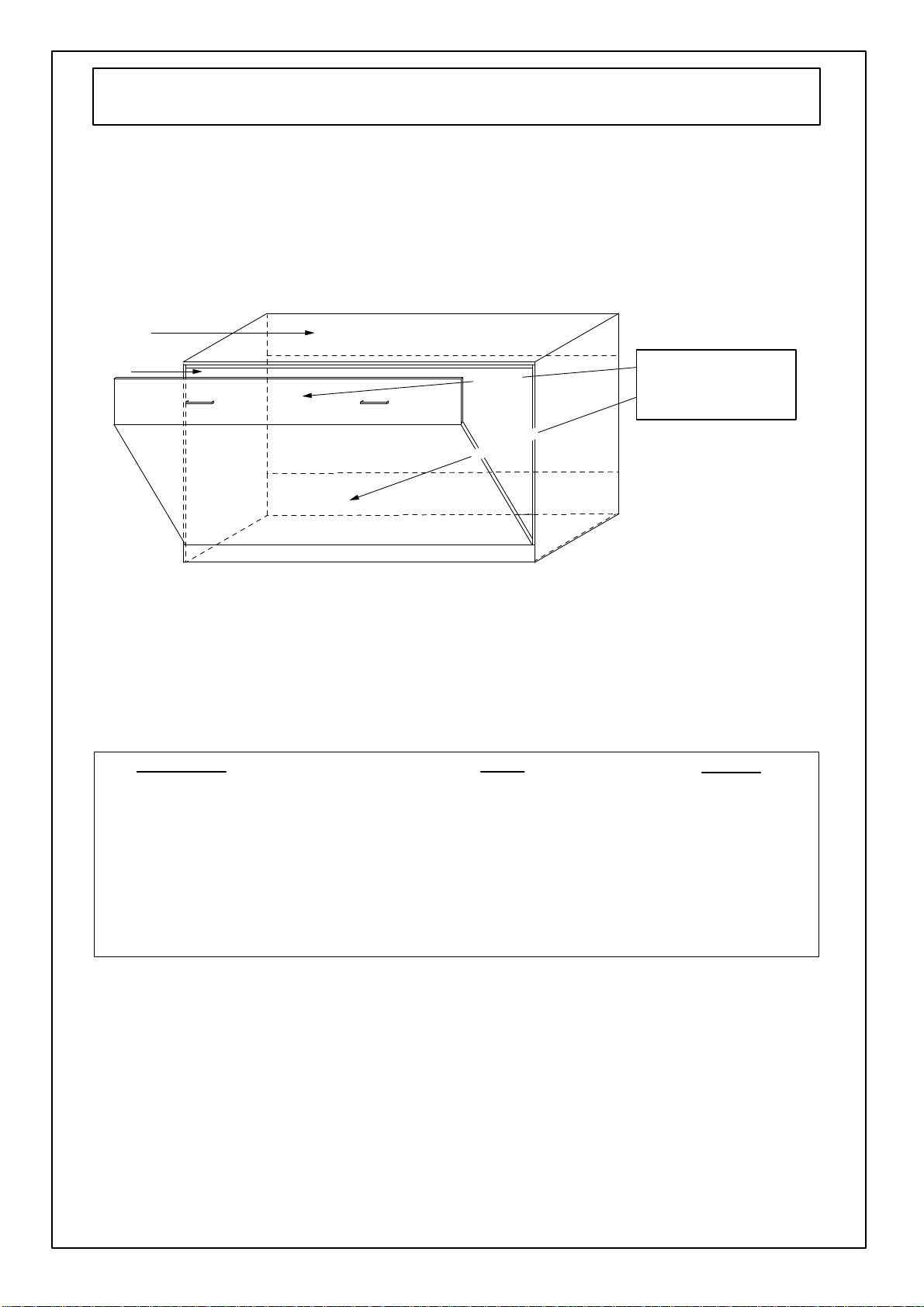

Skirting

Board

Wall

Cut

skirting recess

before

pushing cabinet

against

the

wall

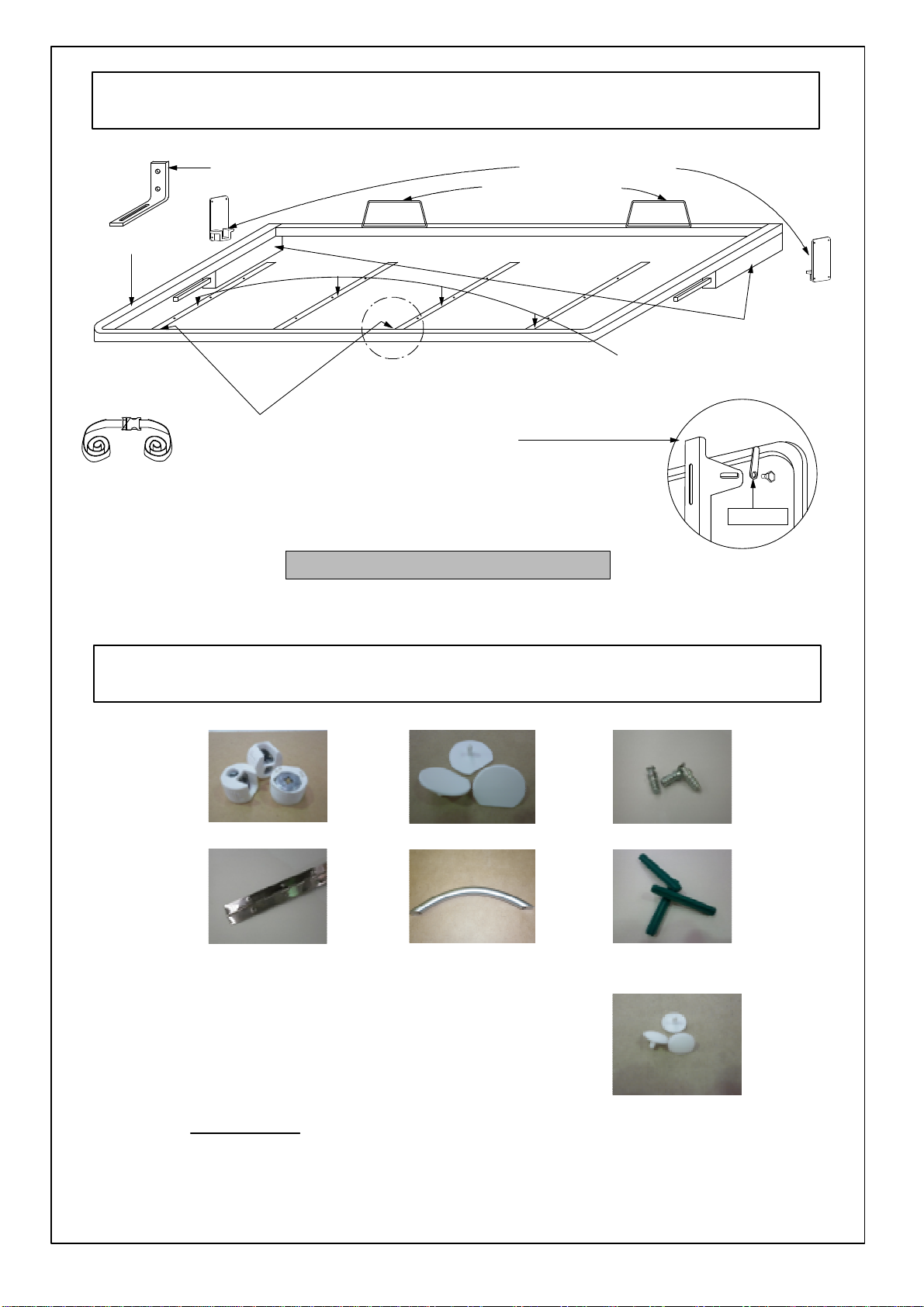

End

Panel

Front

Panel

Base

Panel

DETAIL

B

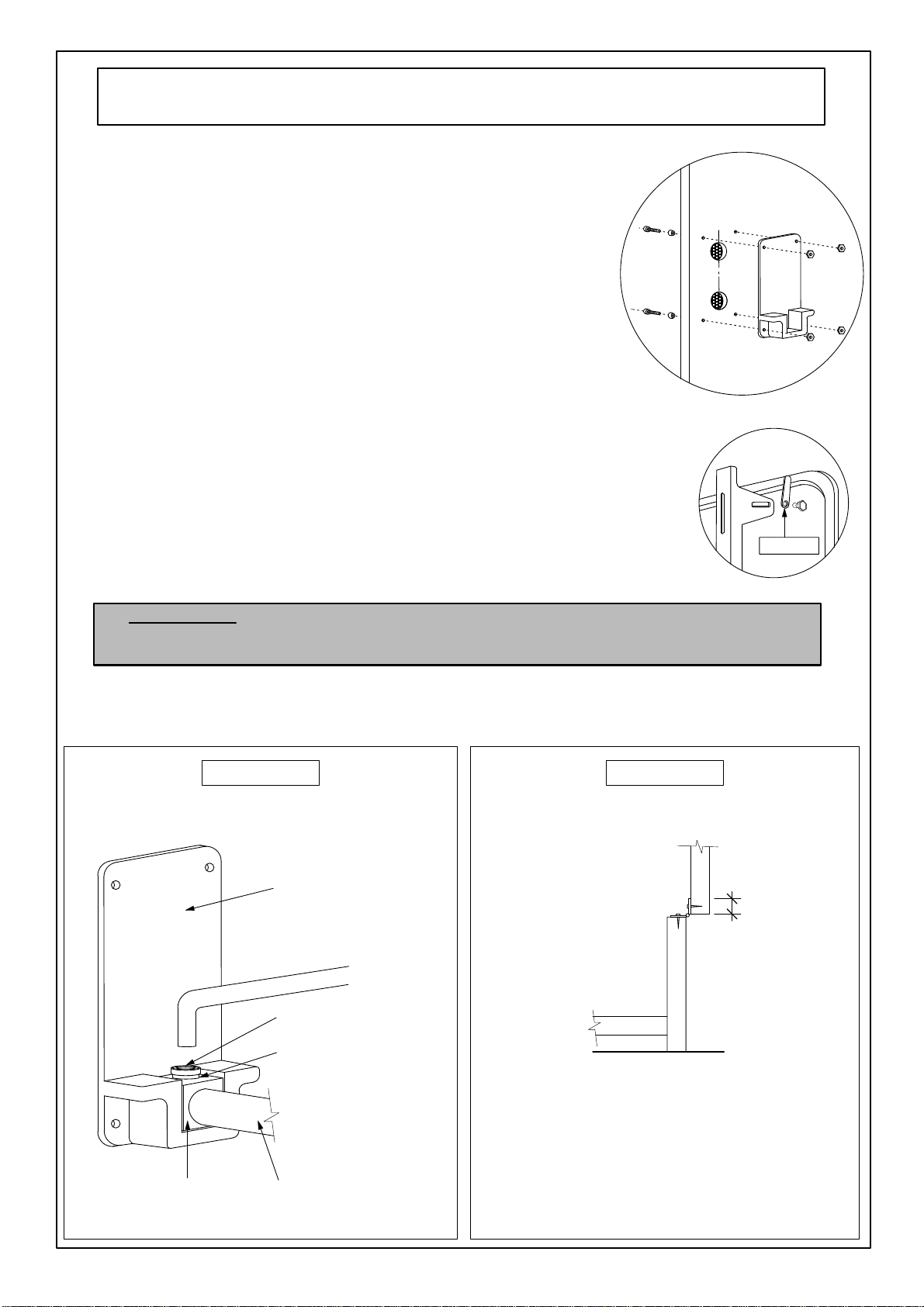

Fastening to wall

DETAIL

A

Wall

plugs

Refer

to

detail

B

Refer

to

detail

A

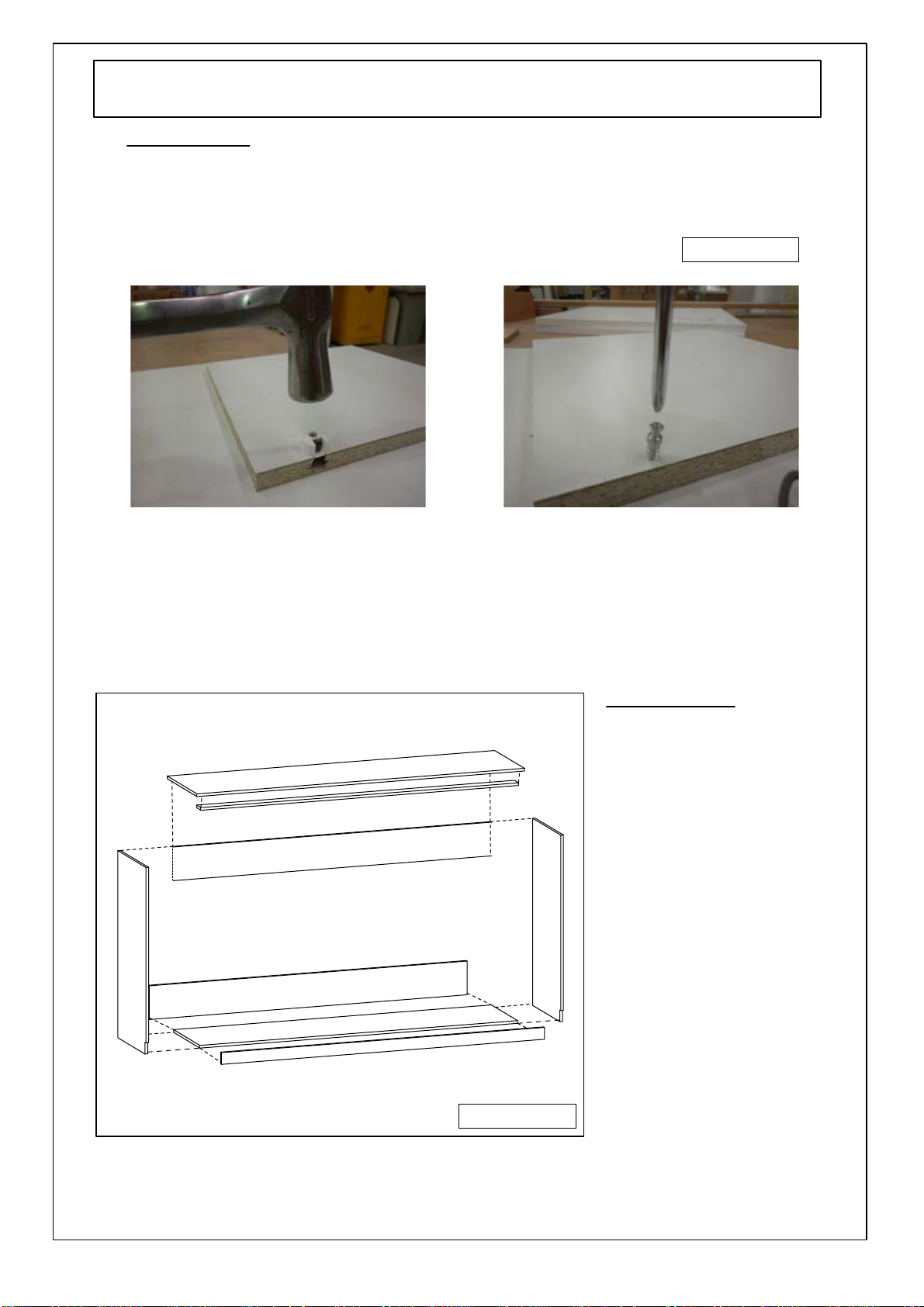

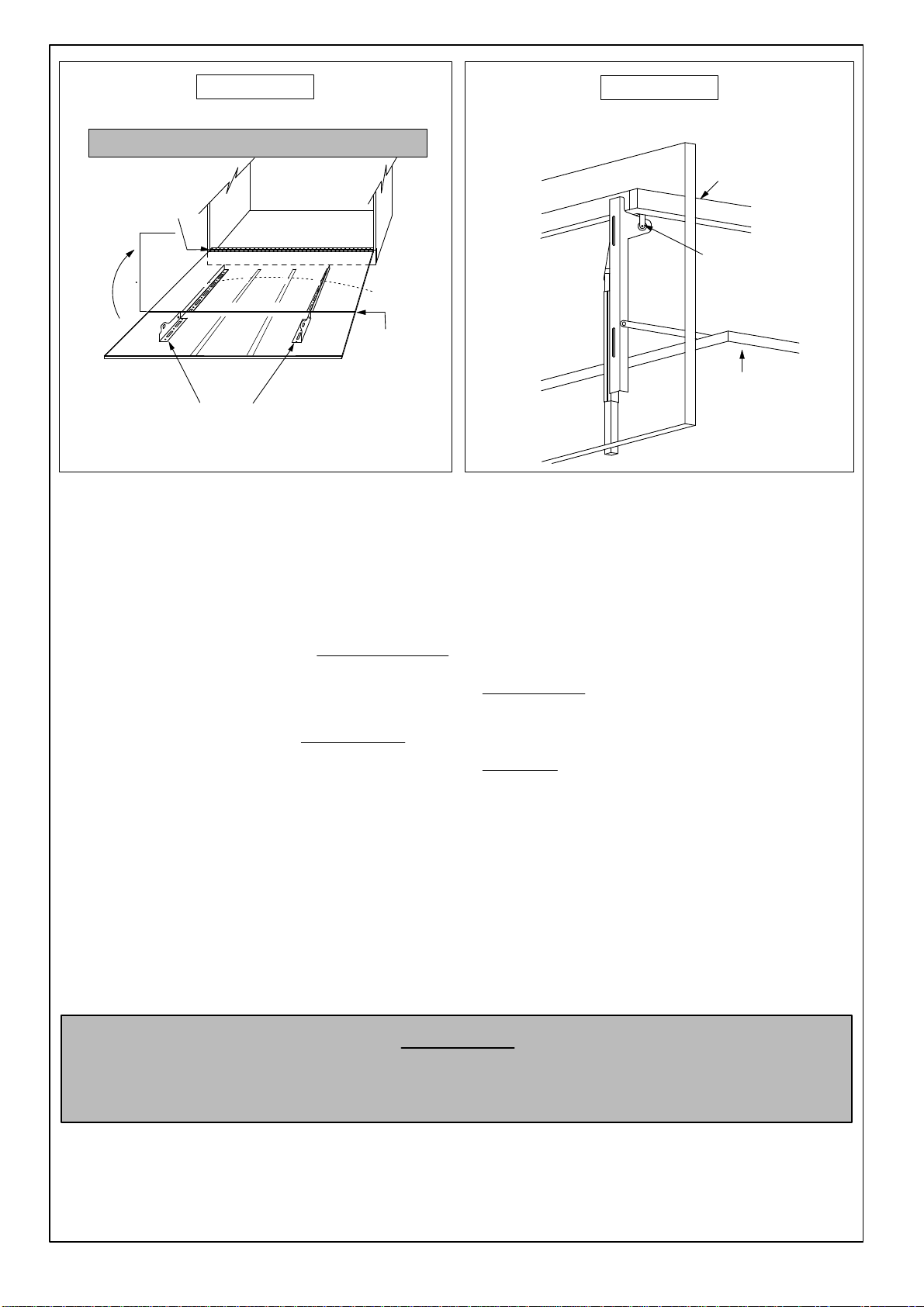

4.

Step2

-

Fixing

Cabinet

To

Wall

*

Lay

cabinet

face

down

with

bottom

facing

the

wall.

*

To

ensure

the

cabinet

is

flush

against the wall when upright, it

may

be

necessary to cut a recess

into

bottom of

left

and

right hand

end

of

cabinet.

*

Place

cabinet

into

position

against

the

wall

and,

using

a

spirit

level

against

either

the

right

or

left

hand

end

and

the

top,

find

the

correct

vertical

and

horizontal

position.

Mark

this

position

on

the

wall

with

a

pencil.

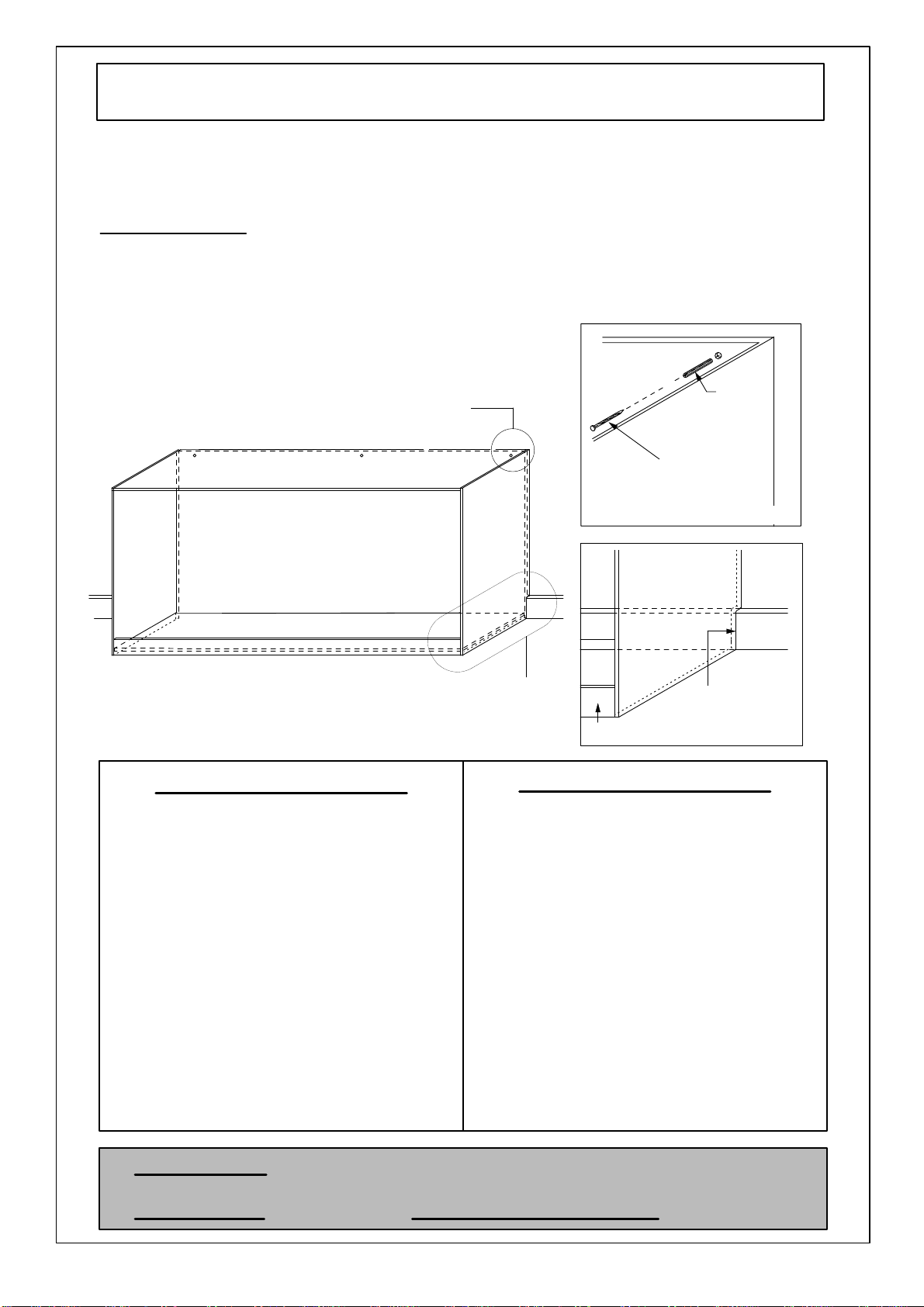

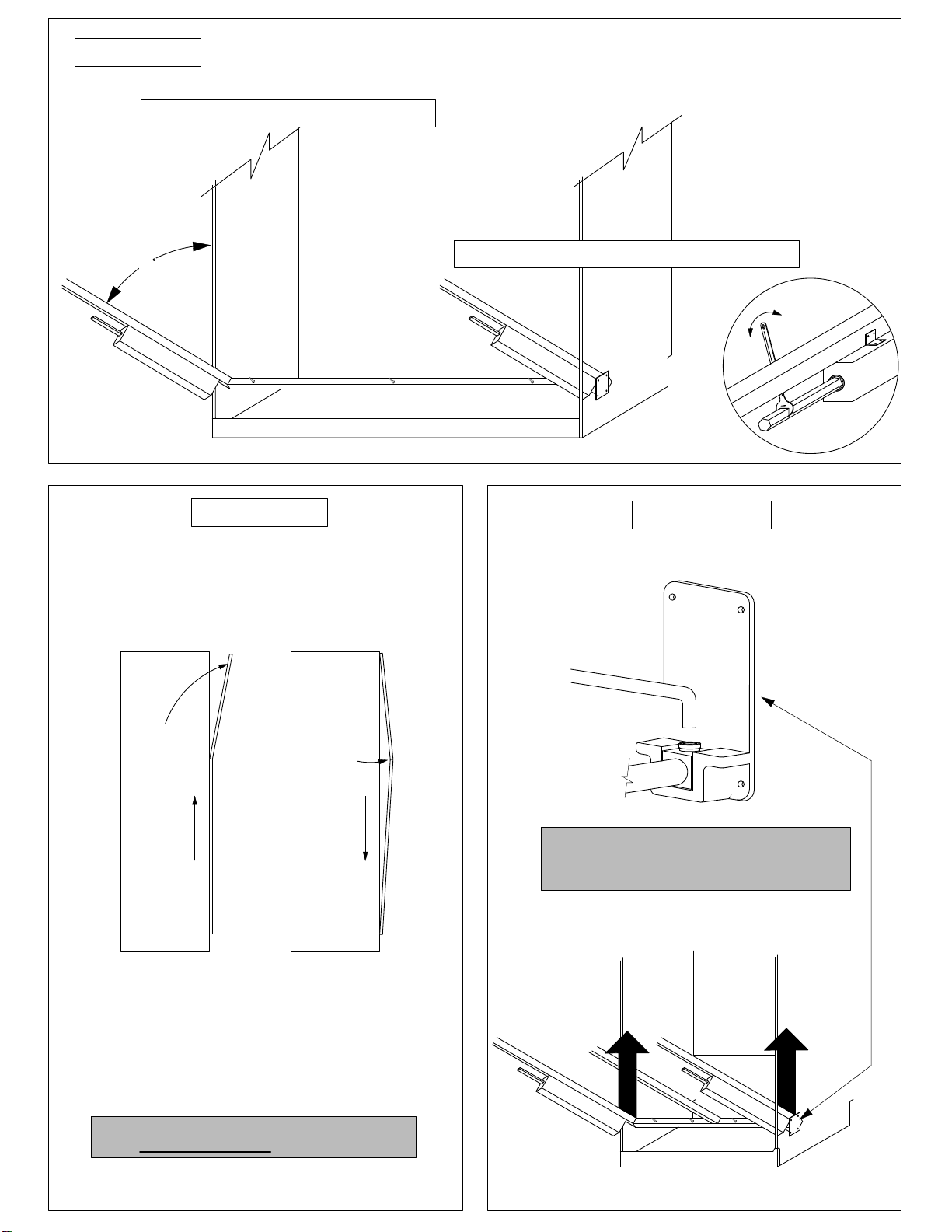

PLEASE NOTE

As

there

is

a

lot

of

tension

in

the

Wallbed

when

in

the open

position,

it

is

very

important

that

the

cabinet

is

securely fixed

to

the wall.

IMPORTANT

NOTE:

Before

moving

cabinet

upright,

ensure

all

cams

are

tightened

securely.

FASTENING

OPTIONS

1

(for

gyprock,

fibro

or

timber

walls)

FASTENING

OPTIONS

2

*

Ensure

cabinet

is

in

correct

vertical

position.

Drill

holes

in

top

of

back

panel

at

top

in

appropriate

position.

*

Using

a

65mm

masonry

bit,

drill

holes

into

wall

and

insert

wall

plugs

supplied.(see

above)

*

Move

cabinet

back

into

place

against

wall.

*

Fix

top

back

panel

to

wall

using

61mm

screws.

Put

on

cover

caps.

(for

brick/masonry

walls)

*

Ensure

cabinet

is

in

correct

position.

*

Locate

wall

studs

*

Drill

holes

in

top

of

back

panel

at top

in

correspording

positions

to

wall

studs.

*

Using

65mm

screws,

screw

cabinet

thru

holes

in

top

of

back

panel

into

studs.

Put

on

cover

caps