1

1. Introduction

You are about to install and operate a SMOG-HOG® PSG

operating on the principle of electrostatic precipitation. PSG

removes submicron, airborne particulate with high efficiency and

at a uniquely low expenditure of energy. With proper handling

and installation, the PSG becomes a powerful tool in controlling

objectionable emissions from a wide range of processes.

The PSG can vary in options, consisting of working groups

of collection components which may, in turn, be preceded or

followed by complimentary conditioning equipment. The PSG

may take the form of a simple component cabinet for inclusion in

a large air handling system or may be a self-sufficient air pollution

control package. Since the PSG generally becomes an integral

part of a process exhaust network, installation should be carefully

planned, starting with mechanical layout drawings and electrical

wiring diagrams provided by Parker. Reading this manual is

important to the successful installation and operation. The PSG

Series has been built to rigid specifications. As with all precision

equipment, the system requires periodic care and maintenance.

This manual contains instructions for standard maintenance and

manual cleaning of components. If the system is equipped with In

Place Cleaning, there is a separate owner’s manual. If assistance

is required please contact Parker Industrial Gas Filtration and

Generation Customer Service, 4087 Walden Avenue, Lancaster,

NY 14086, 1-800-343-4048.

1.1 Description of Operation

PSG Series is a two-stage, Penney-type electrostatic precipitator

used for removal of submicronic hydrocarbon emissions of

smoke and other airborne contaminants. The two “stages”

consist of an ionizing section and a collecting section, combined

in one assembly as a unicell. Each ionizing section consists

of a series of (10 mil) wires charged to a high DC voltage and

centered between a like series of grounded plates. This high

voltage differential generates an intense electrostatic field where

airborne particles are “ionized,” i.e., positive polarity. Each

collecting section consists of a large number of parallel cell

plates, alternately charged at high DC voltage (the same polarity

as the ionizer but about half the voltage magnitude) and ground

potential, thus forming a magnetic field. Charged particles are

simultaneously repelled by the cell charged plates (smaller

dimensional plates) and attracted to cell ground plates (large

dimensional plates). The result being a highly efficient removal

of charged particulate from the airstream as it passes through

the electrostatic precipitator. The total current to both the ionizer

and collector cell circuits is below 5 milliamps which is non

lethal. Unicell components are usually preceded and/or followed

by mesh filters to assure even distribution of air, at low velocity.

Air movement is provided by a system blower located behind

the unicell components that exhausts cleaned air at a specified

cfm rate. More complex systems can include other conditioning

equipment.

1.2 System Definitions

PSG Series is designed for rigorous, often continuous, smoke

and particulate removal duty. The system includes mechanical pre

filters (as applicable), unicells (combination ionizer and collection

cell), power pack enclosures and pre/after filters. The PSG Series

has been tested to operate in accordance with national listing

standards of agencies such as Underwriters’ Laboratories (UL)

and ETL, with local approvals from selected cities as required.

PSG units are designed for installation in customer ducting where

other system components, including the blower, may be provided

by others. PSG systems can include blowers, skids and other

factory-assembled equipment, which arrives in the field ready for

installation.

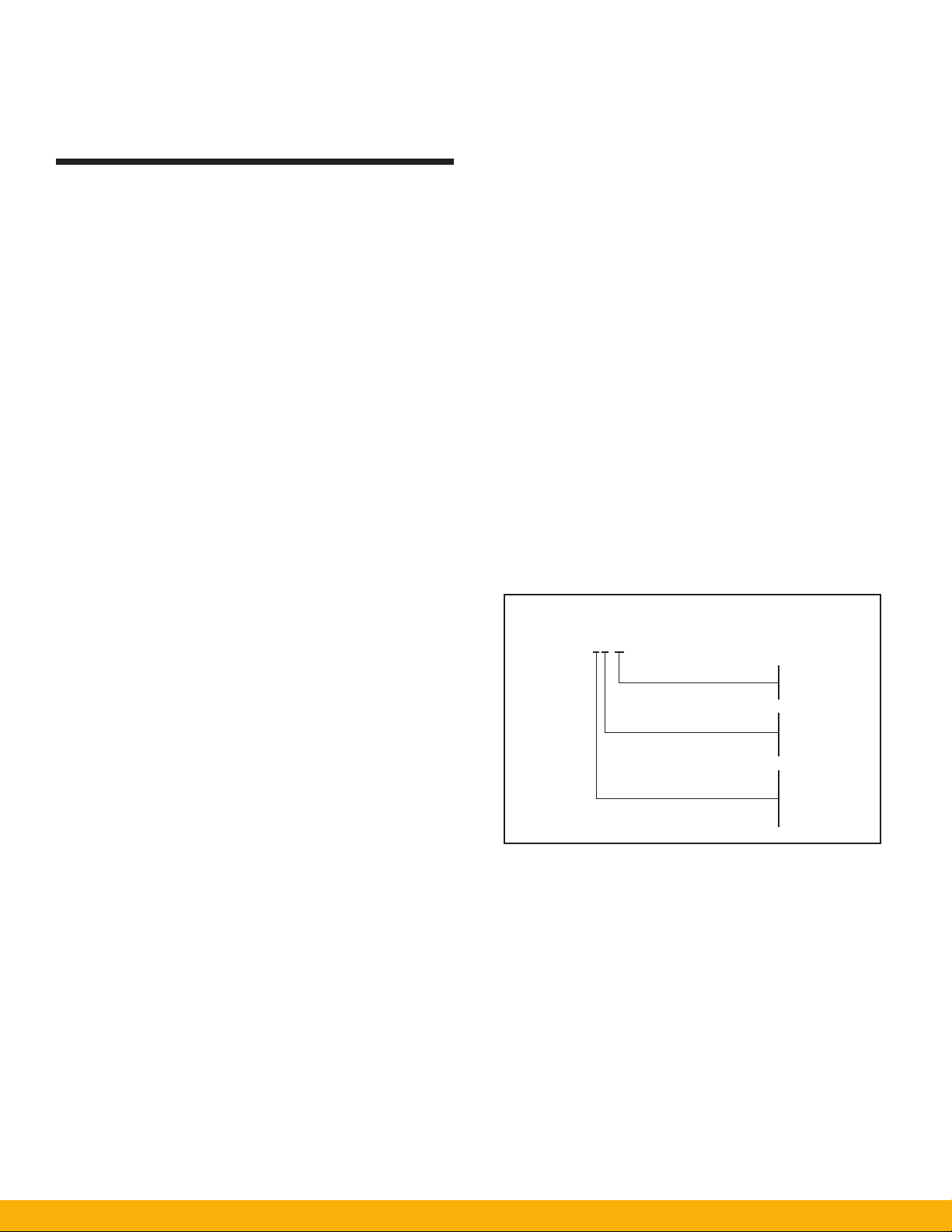

1.3 Unit Nomenclature

PSG systems may include various combinations of features

connected in series in the direction of airflow. The PSG’s

configuration code is defined with a series of letters. Refer to

Figure 1. On “single-wide”, (the width of one module which is

one or two or three unicells placed in series) the access doors to

collecting components face the operator as air flows from left to

right. Opposite side access right to left is also available. “Double

wide” (the width of two modules placed side by side) have access

doors on both sides, each door accessing one module, left to

right, and right to left in one system. Air which flows through

one set of unicells will make a single cleaning “pass.” When an

application dictates, multiple passes can be placed in series in the

direction of airflow. A two-pass system is illustrated in Figure 2.

Figure 1

PSG SERIES NOMENCLATURE

PSG-12-2

1-Single pass

2-Double pass

3-Tr iple pass

1-1 Cell wide

2-2 Cells wide

4-4 Cells wide

3-3 Cells wide

1-1 Tier high

2-2 Tiers high

3-3 Tiers high

4-4 Tiers high

5-5 Tiers high

Typical model identifier:

THIS MANUAL IS COMPILED FOR GENERAL

INFORMATION AND DOES NOT NECESSARILY

REPRESENT ALL OPTIONS OR ACCESSORIES.

CONTACT PARKER CUSTOMER SERVICE

1-800-343-4048 FOR ADDITIONAL INFORMATION

1.4 Description of Components

1.4.1 Power Packs

Each power pack converts 115 volt, single-phase AC power to

high voltage DC for one or two or three unicells (each with one ion-

izer and one collecting section). This combination of components

comprises a working “module.” Standard packs supply positive

DC voltage of 11.0 (nominal) KVDC to each ionizer and 5.5 KVDC

to each collection cell. Power packs with special ratings are sup-

plied on certain applications. Power packs are mounted in power

pack enclosures located on the module doors to the PSG.