Parker AC890PX Series User manual

Other Parker Controllers manuals

Parker

Parker IQAN-LST User manual

Parker

Parker A4AP-DN Manual

Parker

Parker AC30 series User manual

Parker

Parker PAC340 User manual

Parker

Parker AC30 series User manual

Parker

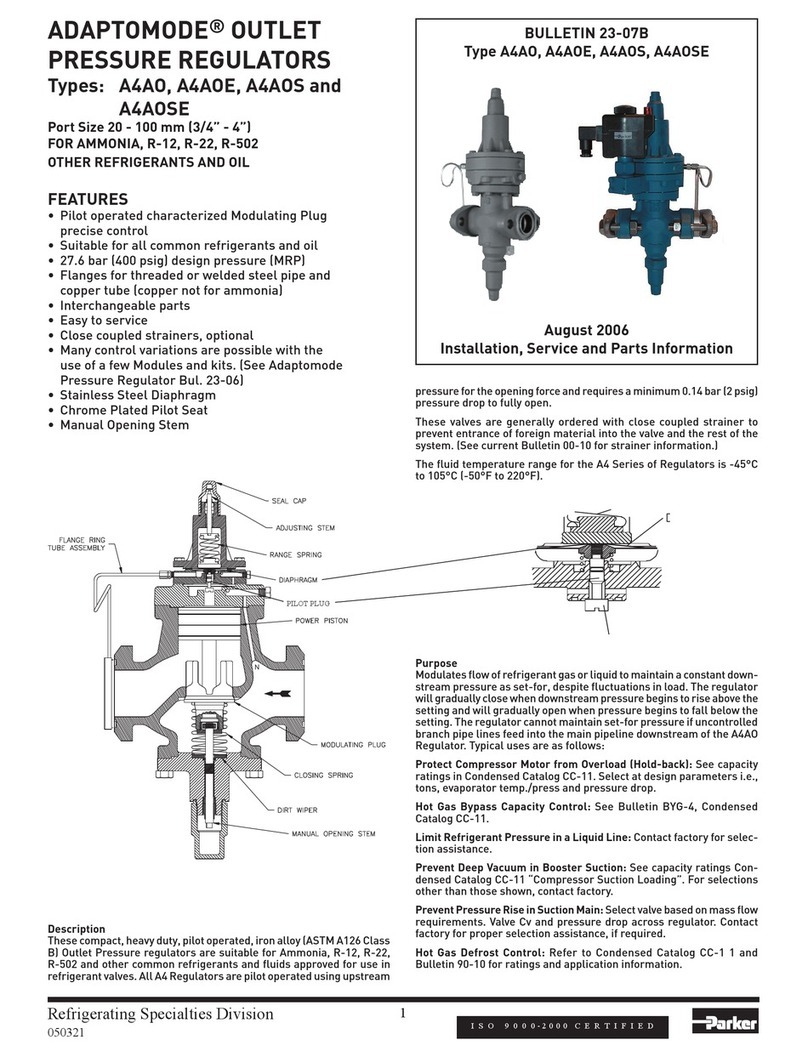

Parker ADAPTOMODE A4AO Guide

Parker

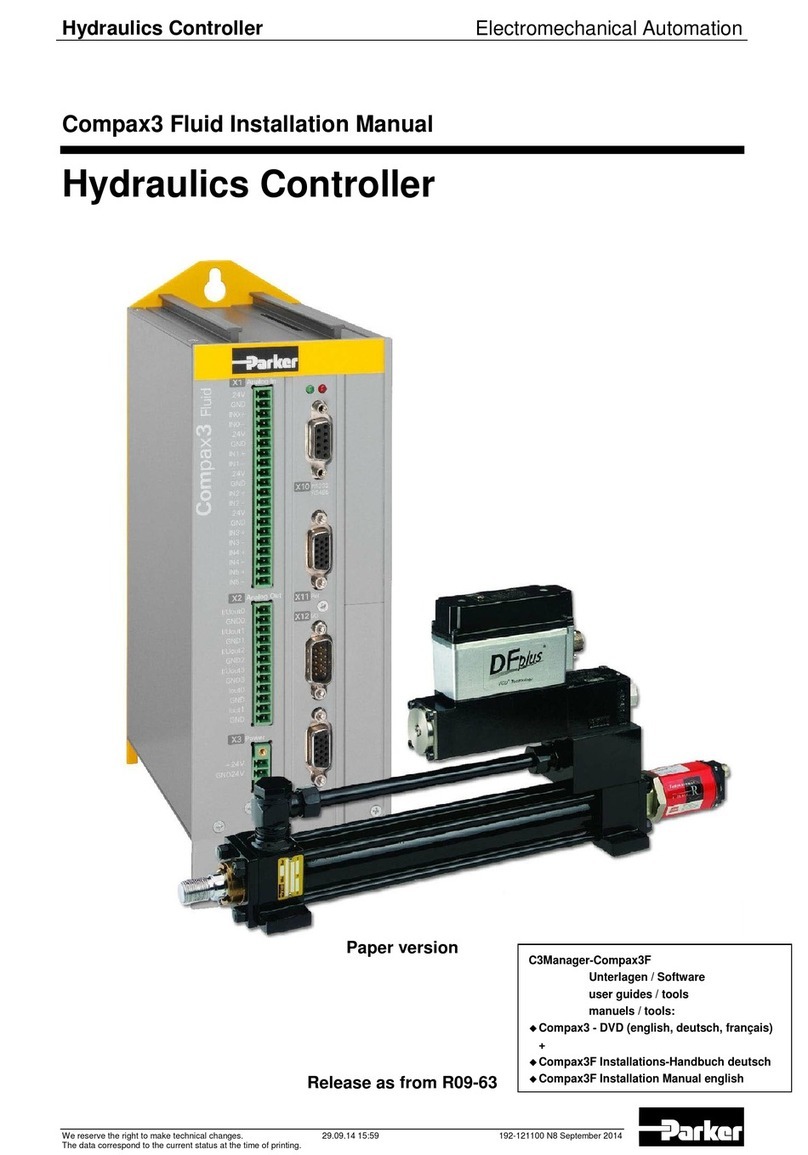

Parker Compax3F Fluid User manual

Parker

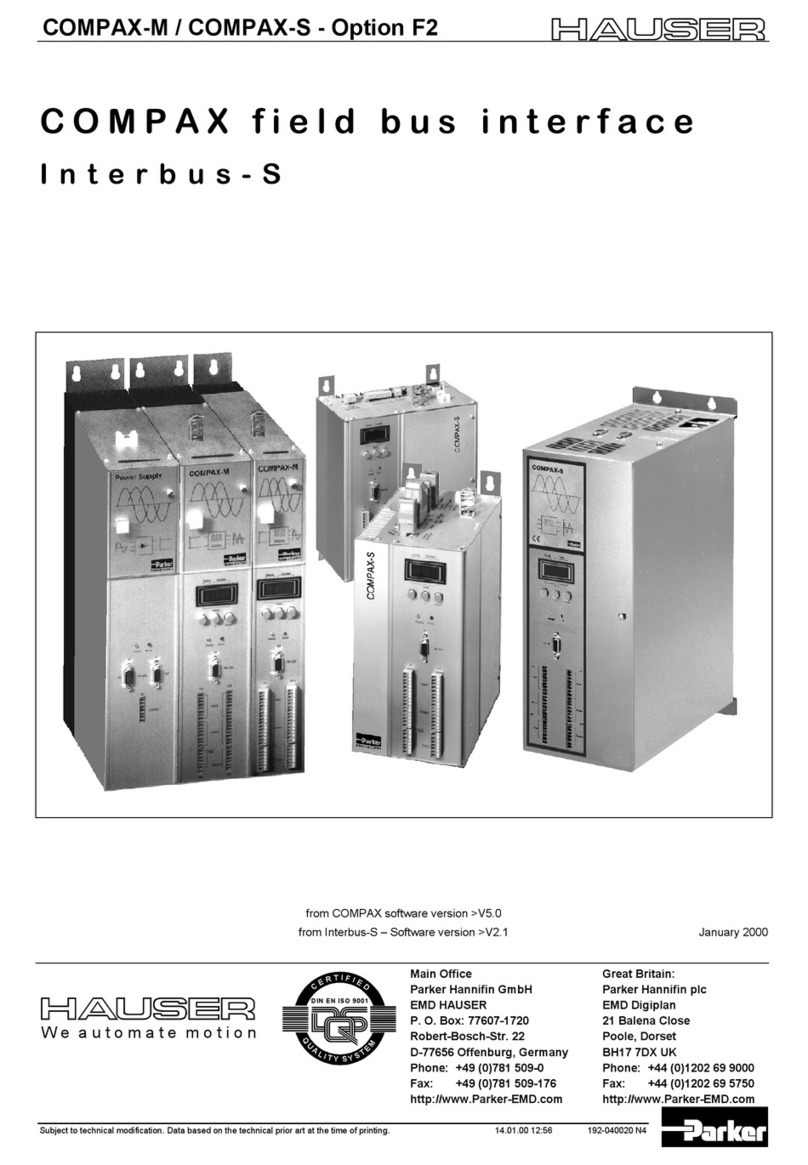

Parker Hauser COMPAX-M Series User manual

Parker

Parker IQAN-MC2 User manual

Parker

Parker ADAPTOMODE A4A Series Guide

Parker

Parker Compax3 Fluid T40 User manual

Parker

Parker ACR9000 User manual

Parker

Parker ACR1505 Manual

Parker

Parker CM2115 User manual

Parker

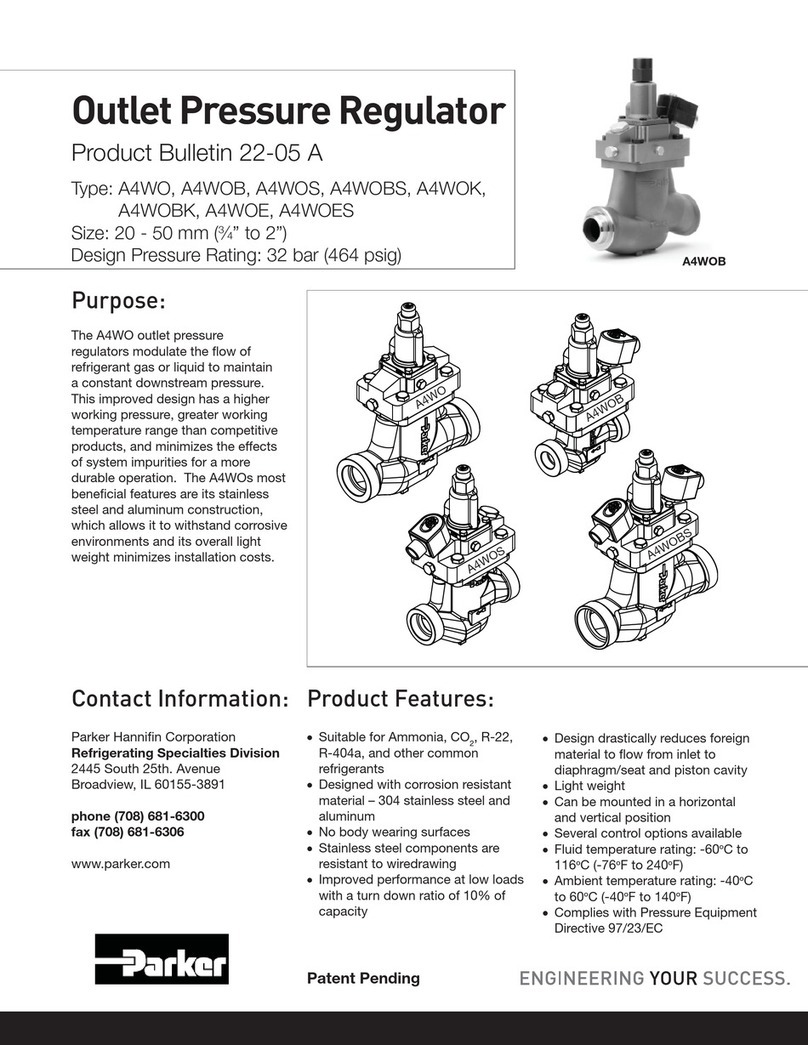

Parker A4WO User manual

Parker

Parker AC30V Series User manual

Parker

Parker 514C User manual

Parker

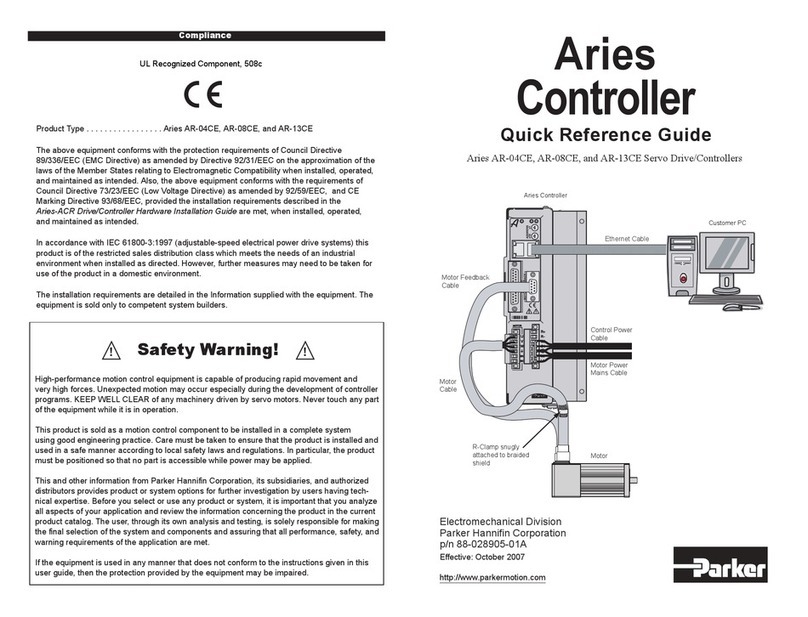

Parker Aries AR-04CE User manual

Parker

Parker R35 Series Quick guide

Parker

Parker Sporlan S3C User guide

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions