Page 4 / SD-324M

standalone system. These settings should be set according to the

compressor manufactuer recommendations. When the Kelvin II

receives a pump down or defrost call at the T3 temperature sensor

terminals (27 and 28) the system will not execute the procedure to

pump down until the minimum relay on time has expired.

Minimum Relay On Time, ront - The amount of time (minutes)

the output of the relay (terminals 19 and 20) must remain on after

it is energized.

Minimum Relay Off Time, roFt - The amount of time (minutes)

the output of the relay (terminals 19 and 20) must remain off after

it is de-energized.

WARNING: The default setting for the Minimum Relay On

and Off time is 0 minutes. For a standalone sys-

tem you must set the values for this feature to be

utilized and prevent compressor short cycling.

NOTE: Use caution. An oversized compressor can cause low

product temperatures during minimum relay on time

cycle.

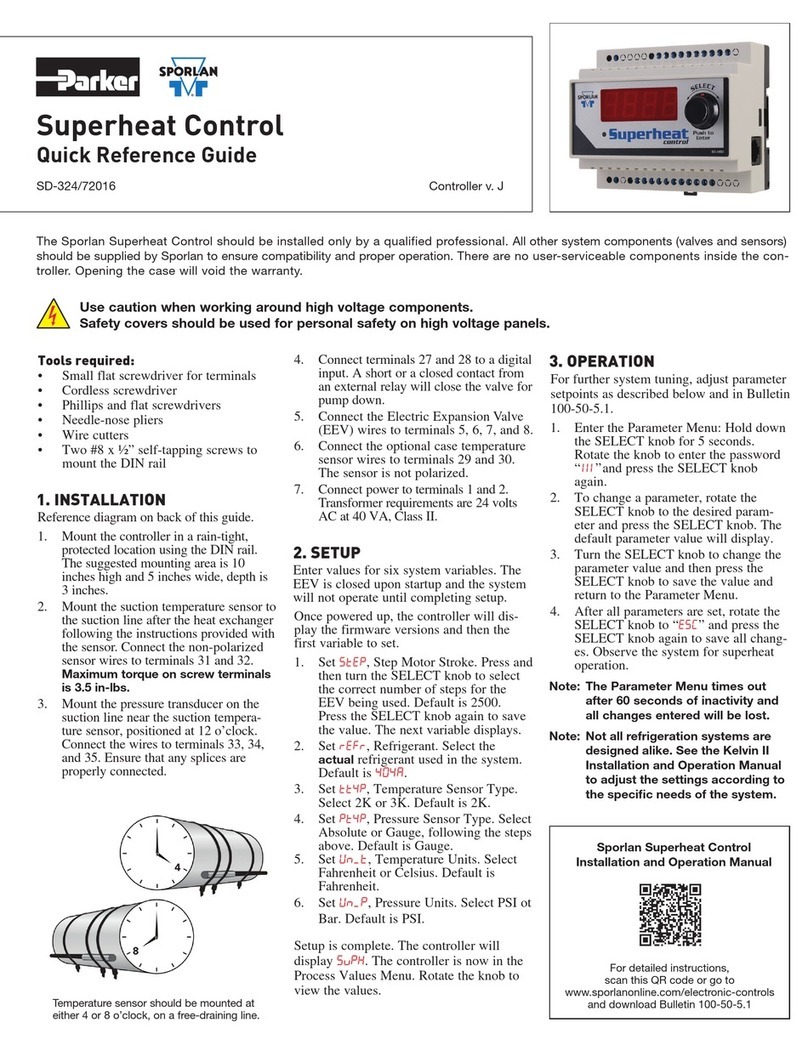

CHILLERS AND AIR CONDITIONERS

Superheat control - Single evaporator:

The Kelvin II controller may be used on single evaporator chill-

ers or air conditioners. The default control scheme is optimized

for quick pull down (coil temperature) and stable holding loads. If

the controller is used on systems with major transient conditions

(impulse heat loads) it may be necessary to adjust the PID control

scheme parameters. See Section 7 - PID Tuning.

Superheat control - Dual evaporator:

On some systems, it may be necessary to control two indepen-

dent evaporator coils. This setup will consist of a Kelvin II with

display and a Kelvin II without display. A network must be estab-

lished between the two controllers; see Section 6 – Controller

Networking. The display can be used to set up both controllers

and to review parameters from each evaporator coil.

ADVANCED FEATURES

Pumpdown

Closing or shorting terminals 27 and 28 (T3) places the controller

in pumpdown mode and closes the EEV. A standard dry contact

relay can be used. During pumpdown signal, the Kelvin II will

open terminals 19 and 20 (relay), which can be used to pilot a

solenoid valve or compressor. During this time, the controller will

shut down the control scheme and prepare for restart. This ensures

maximum control efficiency and system stability.

Bleed System Equalization

Use of an electric expansion valve (EEV) can dramatically

improve the efficiency of a cooling system. By accurately control-

ling the system’s superheat, the EEV achieves full utilization of

the evaporator coil surface area. A drawback to the use of EEVs

with some compressors is the need for off-cycle pressure equal-

ization. Specifically, when the system is off the compressor is

not cycling refrigerant and the EEV is closed, keeping refrigerant

from flowing through the system. This condition can cause high

backpressure on the discharge side of the compressor, and hence

a hard starting condition. Setting a Bleed Step Position, B_ST,

allows a small amount of liquid refrigerant to pass through the

EEV. Normal industry practice is to set a bleed to equalize the

system in 3-5 minutes. The Kelvin II also allows the delay of the

bleed process by setting the parameter b_dL.

Manual Valve Positioning

The Kelvin II can be used to manually control the EEV via local

or remote displays. Access the Setpoint menu and change SPoS to

the desired valve position, between 0 and 100% of full stroke. The

system will time out after 60 minutes of inactivity while in manual

control. To end manual control of the EEV, press the SELECT

knob to go back to SPoS.

The EEV can also be manually controlled via Modbus by writing

a 1 to the “Manual Valve Enabled” coil (see Appendix J - Modbus

Memory Map).

NOTE: To avoid oodback, start with the valve in the low

position. Never leave the sysem unattended while in

manual mode.

ADDITIONAL HELPFUL SYSTEM PARAMETERS

Delay On, d_on - The amount of time the EEV will be placed in

the specified “Delay Percent Open” position before the internal

relay (terminals 19 and 20) is activated. Range is 0 to 60 seconds.

Time starts when the valve reaches the “Delay Percent Open” set-

ting. This feature can be used on small single compressor systems

to position the valve prior to starting the system. Terminals 19

and 20 can be used to pilot a compressor relay.

Delay Off, doFF - The amount of time the system waits to de-

energize terminals 19 and 20. If called to shut off the system, it

closes the EEV and waits for system pumpdown by the specified

Delay Off time, then deenergize the relay (terminals 19 and 20).

Delay Off time starts when EEV is at 0%.

Delay Percent Open, d_St - The position the valve will be

placed in prior to starting. Used in conjunction “Delay On”.

Low Operating Pressure, L_oP - This setting can be used in

smaller systems for startup. If the EEV is not open enough (super-

heat above set point and pressure below LOP) the Kelvin II will

open the EEV 100% to equalize system pressure to maintain

mass flow to keep the system running. It will go back to control-

ling superheat when suction pressure rises above LOP setpoint.

Superheat control takes priority as a safeguard.

Maximum Operation Pressure, H_oP - Used in various systems

to control maximum suction pressure. The Kelvin II limits the

amount of high pressure / high temperature gas going to the com-

pressor by closing the EEV when pressure is within 3 psi of the

Maximum Operating Pressure setpoint.

Max Valve Capacity, HiCP - The maximum opening position of

the valve. Can be used to compensate for an improper, oversized

EEV. If set too low, system superheat may become too high.

Dead Band, dbnd - Provides a smoother operational range

around superheat set point. For tighter superheat control, the

deadband may be decreased. Options are in degrees superheat

around set point, 1 ( +/- 1 degree) or 2 (+/- 2 degrees).

Supermarket Mode, SvPS - Supermarket Mode uses a PID

control scheme that is designed for refrigerated cases that use

evaporator pressure regulators. This default mode provides quick