Parker LTR Series Datasheet

Other Parker Controllers manuals

Parker

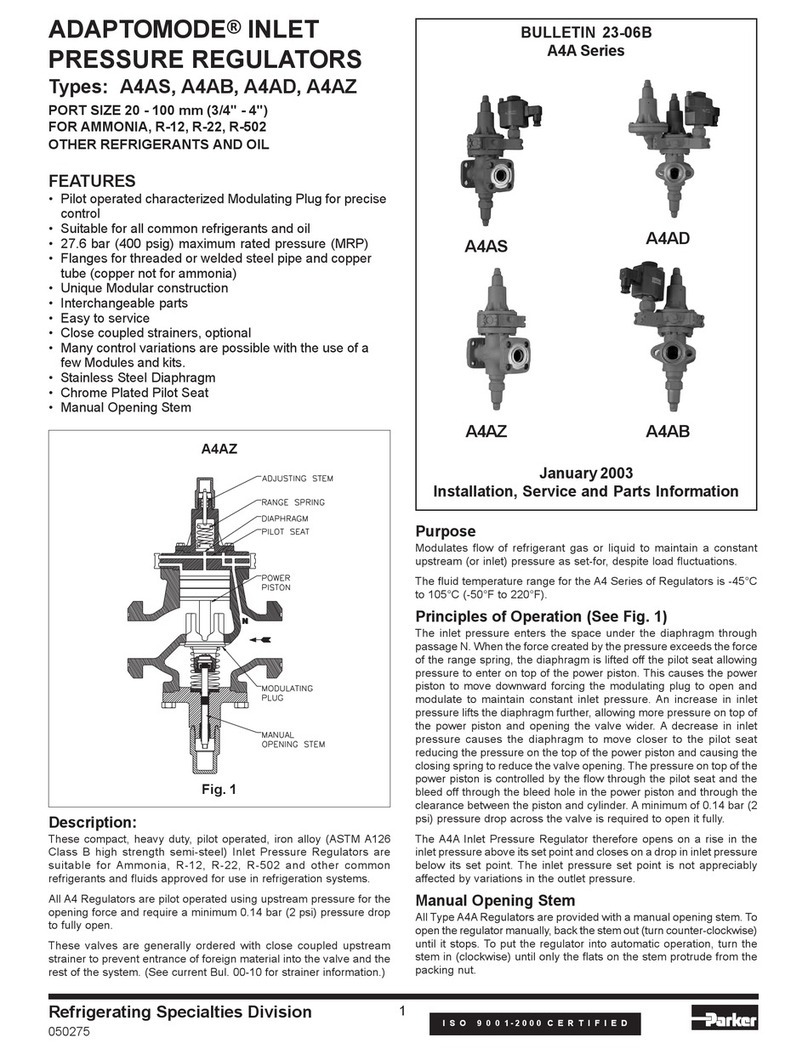

Parker ADAPTOMODE A4AS Guide

Parker

Parker HAUSER HPLA Series User manual

Parker

Parker PAC120 Series User manual

Parker

Parker ADAPTOMODE A4AS-DN Operating and installation instructions

Parker

Parker CM2115 User manual

Parker

Parker ACR8000 User manual

Parker

Parker TQ10X User manual

Parker

Parker A2B-DN User manual

Parker

Parker A4AM-DN Operating and installation instructions

Parker

Parker AC10 series User manual

Parker

Parker AC890PX Series Instruction manual

Parker

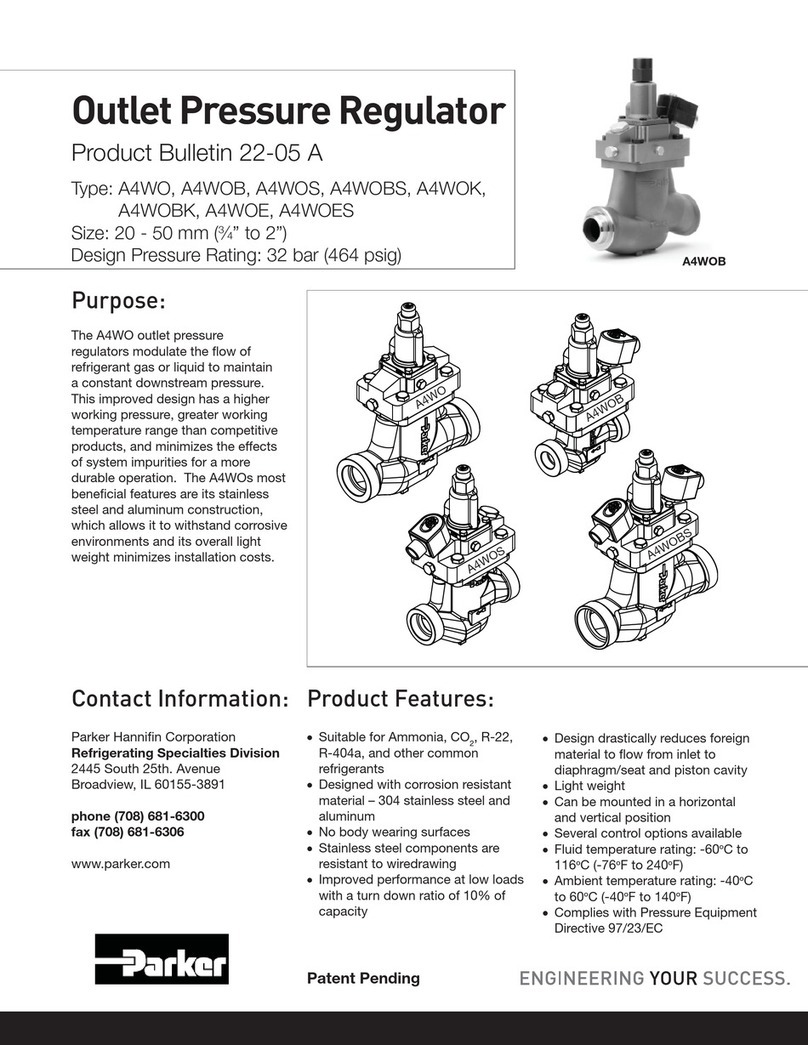

Parker A4WO User manual

Parker

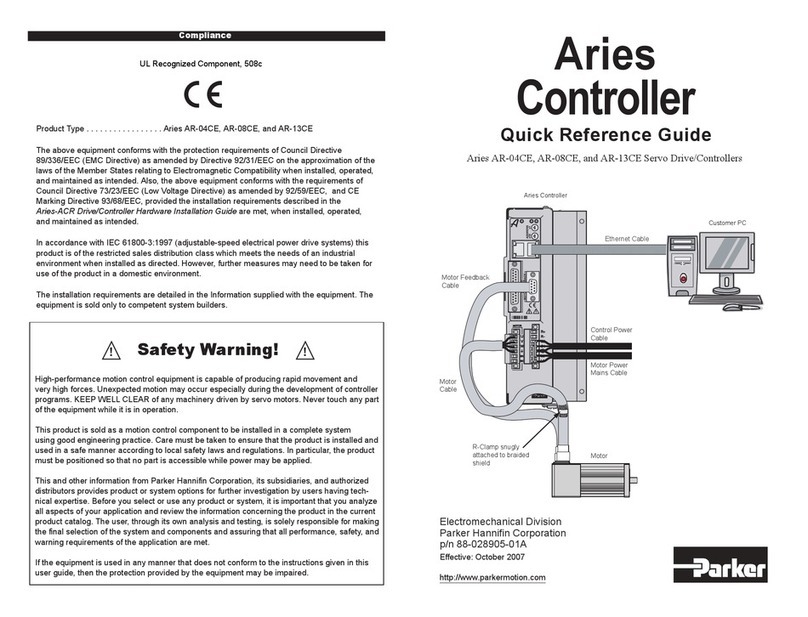

Parker Aries AR-04CE User manual

Parker

Parker 650G Frame 1 User manual

Parker

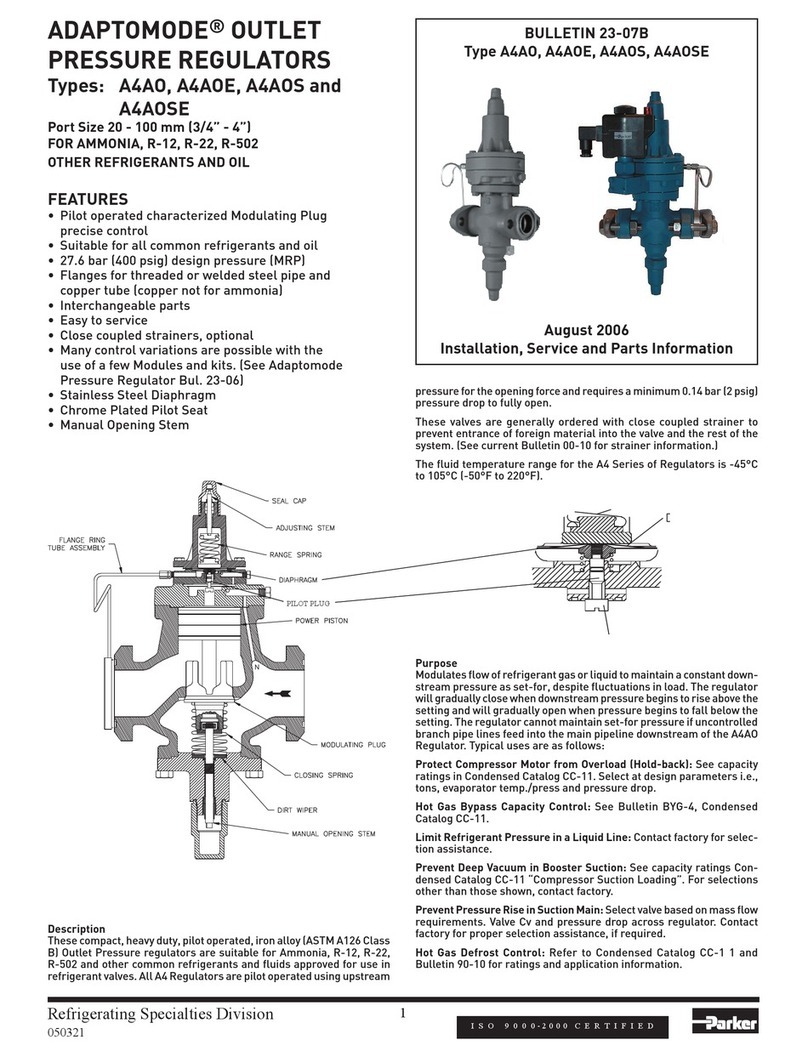

Parker ADAPTOMODE A4AO Guide

Parker

Parker HTR Series User manual

Parker

Parker 506 Series User manual

Parker

Parker HPD2N User manual

Parker

Parker PTR Series Datasheet

Parker

Parker 650 Series User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions