Refrigerating Specialties Division 2

Important Note:

The motor cover should be kept on the motor at all times to

protect it from dust and mechanical damage. No lubrication of

the motor is required.

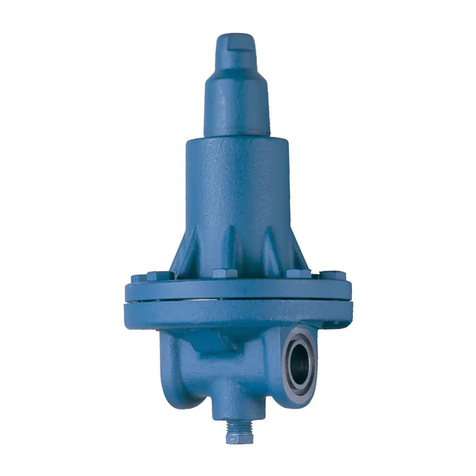

PRINCIPLES OF OPERATION, A4AM (SEE FIG. 1)

Themotorwillrespondto a signalfrom a suitablecontroller, for

example, a thermostat. When the temperature at the sensing

element changes the thermostat, the motor responds immedi-

ately to the signal by rotating the motor shaft. This rotation is

transmittedthroughthecamtothevalvestemandrangespring

tochange theset-point bychanging the springpressure acting

on top of the diaphragm. Whether used as part of a cooling

system to control evaporator pressure, or as part of a heat

reclaim system to control condensing pressure, an increase in

temperature at the thermostat will decrease the spring pres-

sure and lower the inlet pressure thus lowering the evaporator

or condenser temperature. Normally cam rotation is 160 de-

grees and one minute of time is required for the full cam

rotation. Amotorwith240degreesand1.5minuterotationtime

is available and must be so ordered.

TheprinciplesofoperationoftheA4AMSeriesarethesameas

forthebasicA4regulator except forthe varying set-pointof the

motorized pressure pilot. The inlet refrigerant pressure enters

thespace underthe diaphragmthrough passageN. When the

force created by the inlet pressure exceeds the varying spring

force, the diaphragm is lifted off of the pilot seat allowing

pressure to enter the top of the power piston. This causes the

powerpistontomove downward forcingthe modulating plugto

open and modulate to maintain the varying set-point pressure

as dictated by the temperature controller signal to the motor.

An increase in refrigerant inlet pressure, above the set-point

pressure setting, lifts the diaphragm further to allow more

pressureontop ofthe powerpistonand opens thevalvewider.

A decrease in inlet pressure, below the varying set-point

pressure setting, causes the diaphragm to move closer to the

pilot seat reducing the pressure to the top of the piston and

causing the closing spring to reduce the valve opening. The

pressure on top of the piston is controlled by the flow through

the bleed hole in the power piston and through the clearances

between the piston and main valve cylinder. A minimum of 2

psi (0.14 bar) pressure drop across the valve is required in

order for it to open fully.

ADJUSTMENT A4AM

Adjust the controller sensitivity to the desired point according

to the manufacturer’s directions. Open the regulator manually

(manualopeningstembackedout)andrunthesystemuntilthe

temperature at the sensing element reaches the desired level.

Adjust the controller (thermostat) setting to a reading that will

cause the cam of the motor to rotate and stop in center cam

position. Put the regulator back into automatic operation by

turning the manual opening stem in until just the flats on the

stemarevisible. Loosen the pressureadjusting screwlocknut

and turn the adjusting screw until the desired inlet pressure for

this temperature and load condition is reached. Turning the

adjustingscrewinwilllowerthepressure;turningitoutwillraise

the pressure. If after several hours of operation the tempera-

ture is not as desired, readjust the pressure adjusting screw

slightly. Once the desired setting is reached, make sure the

lock nut is tightened. The valve will now modulate in response

to load variation to maintain constant temperature.

PRINCIPLES OF OPERATION, A4AOM (SEE FIG. 2)

Thispressureregulatormodulatestheoutletpressureinaccor-

dance to load requirements as sensed by an electric thermo-

stat or humidistat that varies an electric signal applied to a

motor mounted on the regulator pilot. The motor operation is

describedabove forA4AM, exceptthe A4AOM operatesas an

outlet pressure regulator. Available in standard Range V or

Range D.

Theoutletpressureissensedunderthediaphragmthroughthe

sensing tube, which is part of the Flange Ring-tube assembly.

Whenthe force createdby the outletpressure acting underthe

diaphragm is less than the force of the range spring, the pilot

plug is open, allowing pressure to enter on top of the piston.

Thiscausesthepowerpistontoforcethethrottlingplugtoopen

to maintain constant outlet pressure. Decrease in the outlet

pressure allows the range spring to open the pilot plug further,

allowing more pressure on top of the piston and opening the

throttlingplugfurther. An increasein theoutletpressure will lift

the diaphragm against the force of the range spring, allowing

thepilot plug tostart closing. The pressureontop ofthepower

piston is decreased and the closing spring acts to reduce the

opening of the throttling plug and the flow of fluid through the

regulator. Thepressureontopofthepowerpistoniscontrolled

bytheflow through the pilotseatandthebleed through ableed

hole in the power piston and through the clearance between

the piston and the cylinder. A minimum of 2 psi (0.14 bar)

pressure drop across the regulator is required to open it fully.

ADJUSTMENT A4AOM

Adjust the controller sensitivity to the desired point according

to the manufacturer’s directions. Open the regulator manually

(manualopeningstembackedout)andrunthesystemuntilthe

temperature at the sensing element reaches the desired level.

Adjust the controller (thermostat) setting to a reading that will

cause the cam of the motor to rotate and stop in center cam

position. Put the regulator back into automatic operation by

turning the manual opening stem in. Loosen the pressure

adjusting screw lock nut and turn the adjusting screw until the

desired inlet pressure for this temperature and load condition

is reached. Turning the adjusting screw in will lower the

pressure; turning it out will raise the pressure. If after several

hours of operation the temperature is not as desired, re-adjust

thepressureadjustingscrew slightly. Once thedesired setting

is reached, make sure the lock nut is tightened. The valve will

now modulate in response to load variation to maintain con-

stant temperature.

MANUAL OPENING STEM:

All Type A4 Regulators are provided with a manual opening

stem. To open the regulator manually, back the stem out (turn

counter-clockwise) until it stops. To put the regulator into

automatic operation, turn the stem in (clockwise) until only the

flats on the stem protrude from the packing nut.