HY28-2668-01/GC/NA,EU GOLD CUP®Series - Application Manual

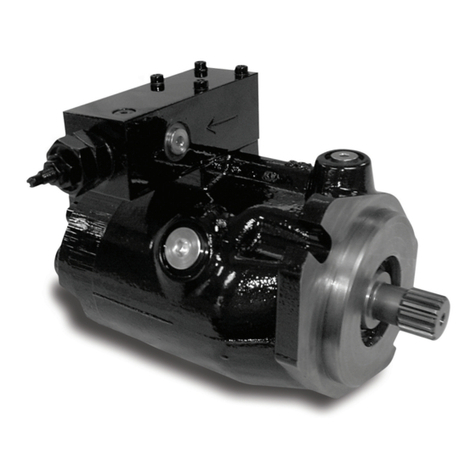

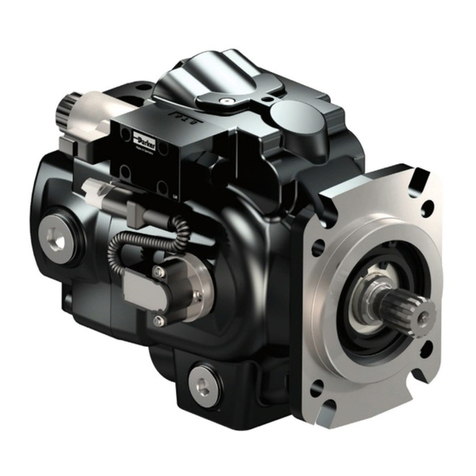

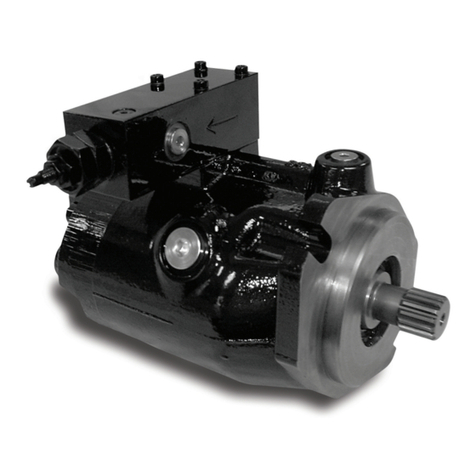

Piston Pumps & Motors

iii

Parker Hannifin Corporation

Hydraulic Pump Division

Marysville, Ohio USA

Contents

The GOLD CUP®package pump and motor internal configuration........................................1.1

Package pump internal configuration .....................................................................................1.1

Figure 1.1 Pump internal configuration-rotating group .......................................................1.1

Figure 1.2 Stroking vane assembly ....................................................................................1.2

Figure 1.3 Stroking vane installation ..................................................................................1.2

Figure 1.4 Pump internal configuration vane chambers and servo stem ...........................1.3

Figure 1.5 Pump internal configuration vane chamber cover and servo plates..................1.3

Figure 1.6 Vane chamber covers........................................................................................1.3

Figure 1.7 Pump internal config. rotary servo input and displacement indicator................1.4

Figure 1.8 Control cover - rotary servo input......................................................................1.4

Figure 1.9 Ring check assembly ........................................................................................1.5

Package motor configuration..................................................................................................1.5

Figure 1.10 Fixed displacement motor ...............................................................................1.5

Figure 1.11 Variable displacement motor ...........................................................................1.6

GOLD CUP®circuitry..............................................................................................................2.1

Package pump circuitry ..........................................................................................................2.1

Figure 2.1 Poppets .............................................................................................................2.1

Servo & replenishing circuits ..................................................................................................2.1

Pressure compensator override .............................................................................................2.2

Figure 2.2 6.0, 7.25 and 8.0 in3/rev. pump circuit................................................................2.4

Figure 2.2.1 6.0, 7.25 and 8.0 in3/rev. pump circuit (ISO standard)....................................2.5

Nomenclature for ISO circuit figure 2.2.1 ...............................................................................2.6

Figure 2.3 11,14 pump circuit.............................................................................................2.7

Figure 2.3.1 11, 14 pump circuit (ISO standard) ................................................................2.8

Nomenclature for ISO circuit figure 2.3.1 ...............................................................................2.9

Figure 2.4 24, 30 pump circuit..........................................................................................2.10

Figure 2.4.1 24, 30 pump circuit (ISO standard) ..............................................................2.11

Nomenclature for ISO circuit figure 2.4.1 .............................................................................2.12

Package motor circuitry ........................................................................................................2.13

Figure 2.5 GOLD CUP®package motor circuit.................................................................2.13

GOLD CUP®controls..............................................................................................................3.1

Rotary servo input ..................................................................................................................3.2

Figure 3.1 Control cover-rotary servo input........................................................................3.2

Spring centering rotary servo .................................................................................................3.3

Figure 3.2 Spring centered rotary servo (zero stroke)........................................................3.3

Figure 3.3 Spring centered rotary servo (on stroke)...........................................................3.3

Adjustable stops .....................................................................................................................3.4

Manual screw adjustment.......................................................................................................3.4

Figure 3.4 Manual screw adjustment..................................................................................3.4

Motor cylinder control .............................................................................................................3.4

Figure 3.5 Motor cylinder control (max. stroke) ..................................................................3.5

Figure 3.6 Motor cylinder control (min. stroke) ...................................................................3.5

Pump two position cylinder control.........................................................................................3.6

Figure 3.7 Pump two position cylinder control....................................................................3.6

Pump three position cylinder control ......................................................................................3.6

Figure 3.8 Pump three position cylinder control .................................................................3.7

Motor electrohydraulic cylinder control (2M* motor control) ...................................................3.7

Figure 3.9 Motor electrohydraulic cylinder control (full stroke) ...........................................3.7

Pump two position electrohydraulic cylinder control (2M* pump control) ...............................3.7

Figure 3.10 Pump two position electrohydraulic cylinder control........................................3.8

Pump three position electrohydraulic cylinder control (2N* control) .......................................3.8

Figure 3.11 Three position electrohydraulic cylinder control ..............................................3.8

Automatic brake and neutral bypass control...........................................................................3.9

Figure 3.12 Automatic brake and neutral bypass (400 and 500 series)

(input & output at zero stroke) ............................................................................................3.9

Figure 3.13 Automatic brake and neutral bypass (400 and 500 series)

(input and output on stroke)..............................................................................................3.10

Figure 3.14 Automatic brake and neutral bypass (400 and 500 series)

(input zero, output on stroke)............................................................................................3.11

Figure 3.15 Automatic brake and neutral bypass (800 and 900 “C” series)

(zero stroke) .....................................................................................................................3.12

Figure 3.16 Automatic brake and neutral bypass (800 and 900 “C” series)

(full stroke)........................................................................................................................3.12

Torque limit override control .................................................................................................3.12

Figure 3.17 Torque limit override circuit............................................................................3.13

Figure 3.18 Torque limit override shoe .............................................................................3.13

Figure 3.19 Torque (horsepower) limit override ................................................................3.14

SECTION 1

GOLD CUP®package pump and motor

internal configuration

SECTION 2

GOLD CUP®circuitry

SECTION 3

GOLD CUP®controls

www.comoso.com