10

Axial Piston Pumps

Series eP2 / eP3 – Electronic Controls

Installation and setup manual

Parker Hannifin Manufacturing Germany GmbH & Co. KG

Pump & Motor Division Europe

Chemnitz, Germany

Bulletin MSG30-2901-INST/UK

Start the pump at low speed.

Continue low pressure / low speed operation until

pump and system are properly filled and free of

air bubbles.

Re-check fluid level in tank. Gradually increase

pressure and speed over a timeframe of 5 to 10

minutes. Check if all hoses / pipes and connec-

tions are leak free and tight. Be alert for trouble

as indicated by changes in sound, system shocks

and air in fluid.

If the pump does not build up pressure, double-

check the installation.

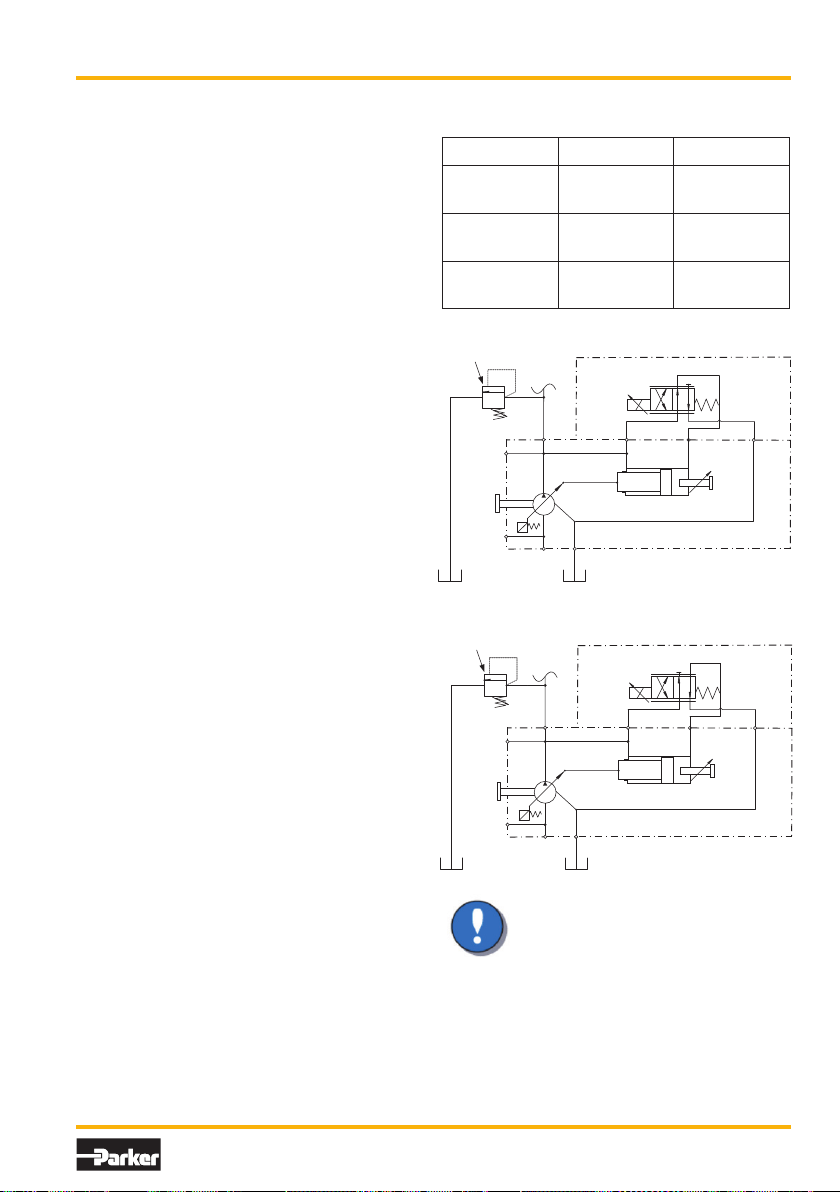

4.2. Temperature

Check temperature range of selected seal material

and compare with maximum system and ambi-

ent temperature. The following limitations refer

to average case drain temperature (measured at

drain port), which can be up to 20°C higher than

in the reservoir:

N/D NBR O-rings, FPM shaft seal(s) [-25…+80]°C

B/Q NBR O-rings, NBR shaft seal(s) [-40…+80]°C

V/T FPM O-rings, FPM shaft seal(s) [-25…+80]°C

4.3. Inspection and Maintenance

In general the service life of a piston pump is de-

termined by its bearing lifetime, which is primarily

a function of pressure and drive speed cycle, shaft

load, temperature as well as quality of the hydraulic

fluid. In order to provide for maximum pump life it is

strongly recommended to adhere to the following

inspection routine.

Continuous monitoring:

Operating temperature, noise levels, vibration.

Daily check up:

Oil level and frothing in reservoir, pump leakage.

Monthly check up:

Fixtures.

Yearly:

Oil check (viscosity, contamination, wear).

Check swash angle sensor calibration, recalibrate

if necessary.

5.Trouble Shooting

Component problems and circuit problems are

often interrelated. An improper circuit may oper-

ate with apparent success but will cause failure of

a particular component within it. The component

failure can be the effect, not the cause of the

problem.The following overview on the most typical

issues is offered to provide support in locating and

eliminating the cause of problems. Please consult

Parker for further questions.

Effect:

Noisy Pump / Erosion on barrel and valve plate

Possible cause:

Air in fluid, cavitation (possibly resulting from leak-

ing inlet connection, low fluid level in reservoir,

return lines above fluid level, excessive viscosity of

hydraulic fluid / low temperature operation, exces-

sive shaft speed, insufficient inlet pressure)

Effect:

High wear in pump

Possible cause:

• Excessive loads (operating conditions notac-

cording to pump ratings)

• Fluidcontamination(possiblyresultingfromim-

proper filter maintenance, reservoiropenings)

• Improperuid(excessiveviscositylevels,

breakdown of fluid, incorrect additives)

• Waterinuid(possiblyresultingfromcondensa-

tion, faulty breather / strainer)

Effect:

Excessive Heating

Possible cause:

• Excessive pump leakage (possible causedby

internal damage, fluid viscosity belowrated

minimum)

• Faultyheatexchanger

• Reservoirissues(toolittleuid,heatpickupfrom

surrounding equipment