English

– 7

SAFETY INSTRUCTIONS

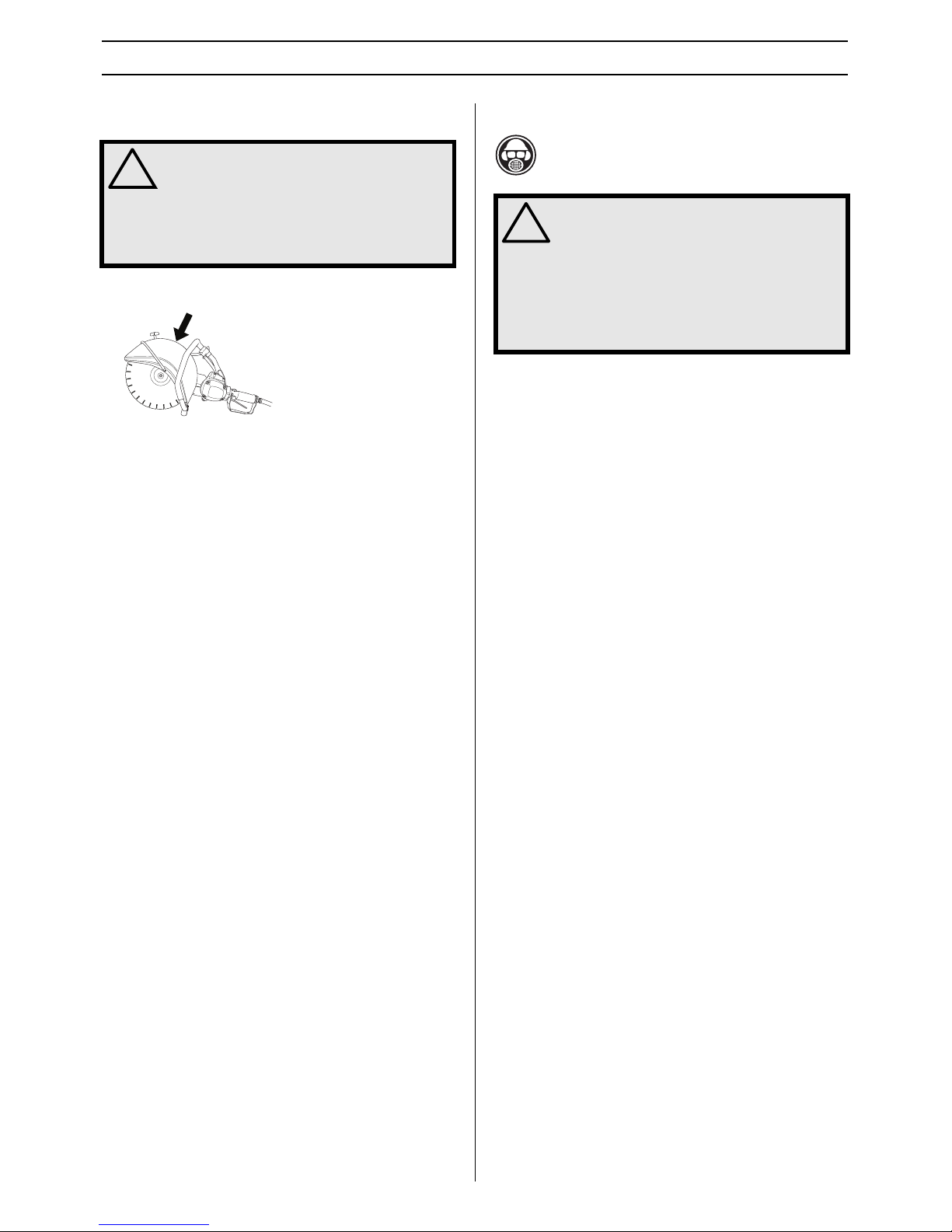

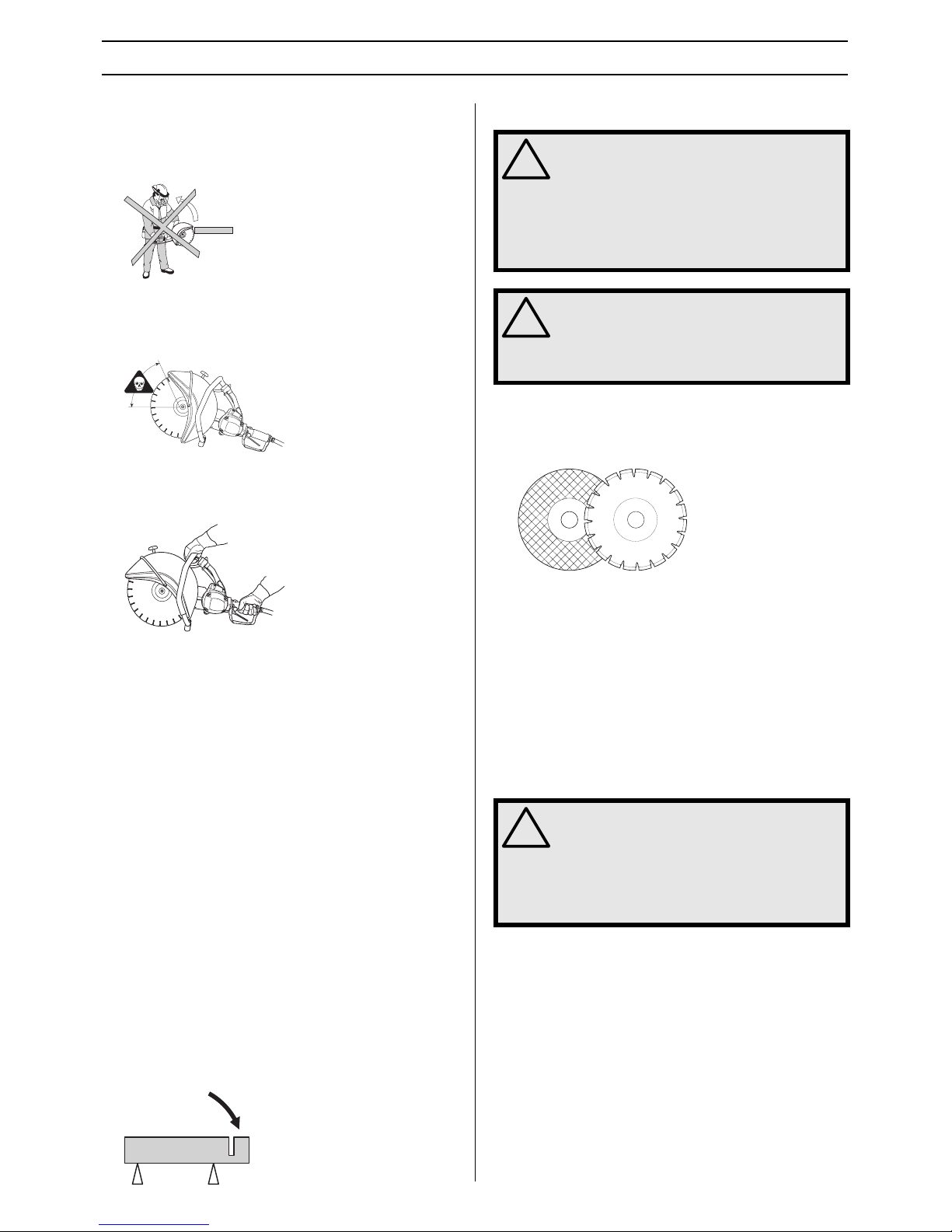

Checking the blade guard

Check that the guard is complete and without any cracks or

deformations.

General safety precautions

• A power cutter is designed to cut hard materials, such as

masonry. Observe the increased risk of kickback when

cutting soft materials. See instructions under the heading

How to avoid kickback.

• Do not use the power cutter until you have read the entire

contents of this Operator’s Manual.

All servicing, in addition to the points listed in the section

”Control, maintenance and service of the power cutter’s

safety equipment”, should be carried out by trained

service specialists.

• Never use the machine if you are tired, if you have drunk

alcohol, or if you are taking medication that could affect

your vision, your judgement or your co-ordination.

• Wear personal protective equipment. See instructions

under the heading Personal protective equipment.

• Never use a machine that has been modified in any way

from its original specification.

• Never use a machine that is faulty. Carry out the checks,

maintenance and service instructions described in this

manual. Some maintenance and service measures must

be carried out by trained and qualified specialists. See

instructions under the heading Maintenance.

• Never allow anyone else to use the machine without first

ensuring that they have understood the contents of the

operator’s manual.

Transport and storage

Do not store or transport the power cutter with the cutting

blade fitted.

Store the power cutter in a lockable area so that it is out of

reach of children and unauthorised persons.

All blades should be removed from the cutter after use and

stored carefully. Store cutting blades in dry, frost free

conditions.

Special care should be taken with abrasive discs. Abrasive

discs must be stored on a flat, level surface. If blades are

supplied with a backing pad then a spacer should be used to

keep them flat. If an abrasive disc is stored in humid

conditions, this can cause imbalance and result in injury.

Inspect new blades for transport or storage damage.

General working instructions

Basic safety rules

• Look around you:

- To ensure that people, animals or other things cannot

affect your control of the machine.

- To make sure that none of the above come into contact

with the cutting blade.

• Do not use the machine in bad weather, such as dense

fog, rain, strong wind, intense cold, etc. Working in bad

weather is tiring and can lead to dangerous conditions,

e.g. slippery surfaces.

• Never start to work with the power cutter before the

working area is clear and you have a firm foothold. Look

out for any obstacles with unexpected movement. Ensure

when cutting that no material can become loose and fall,

causing operating injury.Take great care when working on

sloping ground.

• Make sure that no clothes or parts of the body come in

contact with the cutting equipment when it is rotating.

• Keep at a safe distance from the cutting equipment when

it is rotating.

• The guard for the cutting equipment must always be on

when the machine is running.

• Ensure that the working area is sufficiently illuminated to

create a safe working environment.

• Do not move the machine when the cutting equipment is

rotating.

• Always ensure you have a safe and stable working

position.

• Make sure that no pipes or electrical cables are routed in

the area to be cut.

• Ensure that the air hose is behind you when you start to

use the machine so that the hose is not damaged.

!

WARNING! Always check that the guard is

correctly fitted before starting the machine.

Check that the cutting blade is fitted

correctly and does not show signs of

damage. A damaged cutting blade can cause

personal injury. See instructions under the

heading Assembly.

!

WARNING! This section describes basic

safety directions for using a power cutter.

This information is never a substitute for

professional skills and experience. If you get

into a situation where you feel unsafe, stop

and seek expert advice. Contact your dealer,

service agent or an experienced power

cutter user. Do not attempt any task that you

feel unsure of!