ROLLERS – ADJUSTMENT/INSPECTION5

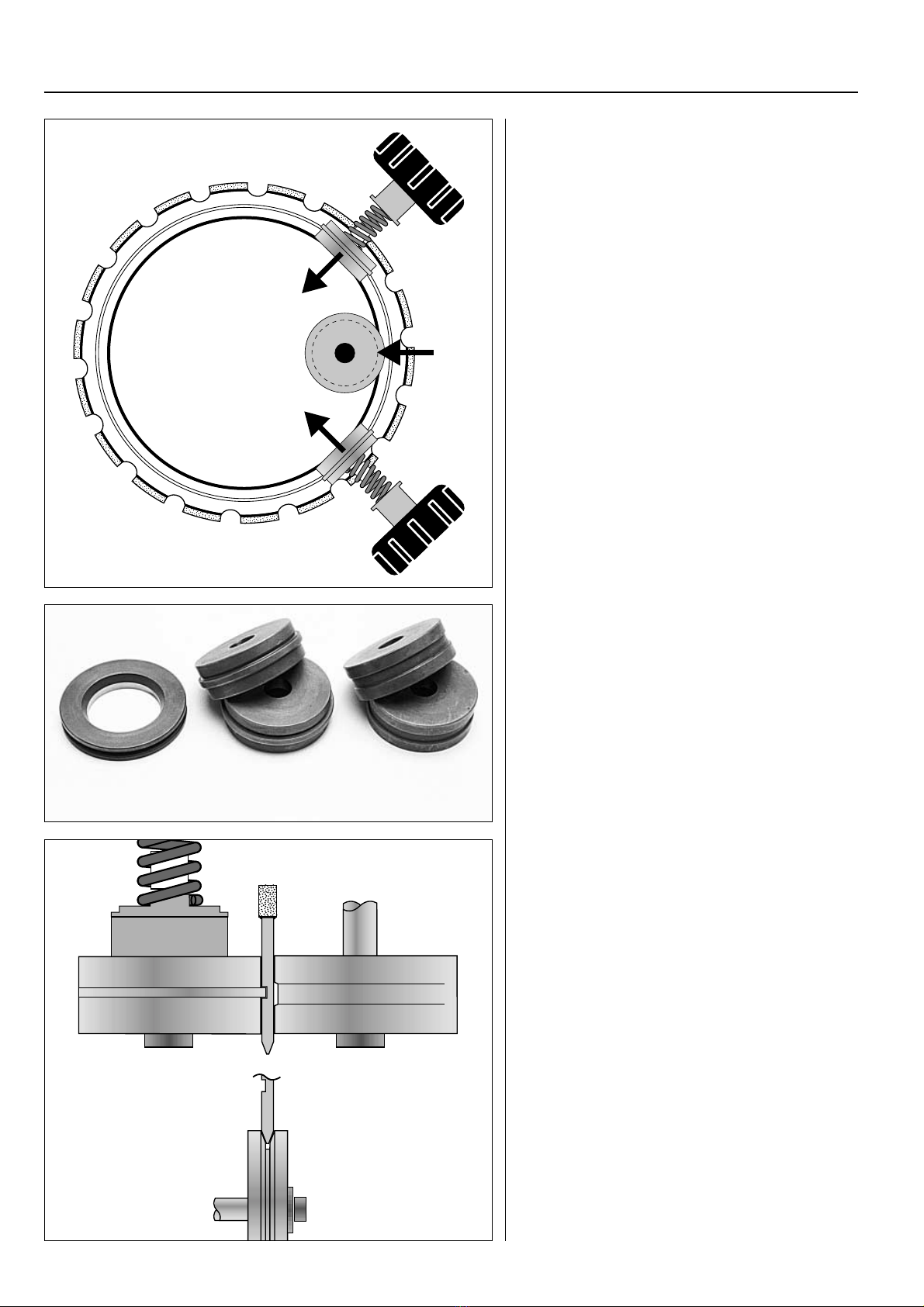

Adjustment

Important – knob unscrewed

The knob should be un-

screwed to its end position.

Undo the lock-nuts

Rough adjustment

Rotate the blade by hand

and tighten the adjustment

screws until the rollers rotate

Fine adjustment

Fine-tune the adjustment to

a position where you can

easily stop the rotation of

the rollers using your thumb

(lower picture).

Tighten the lock-nuts –

final check

Tighten the lock-nuts firmly

and carry out a final check of

the adjustments.

Tighten the knob

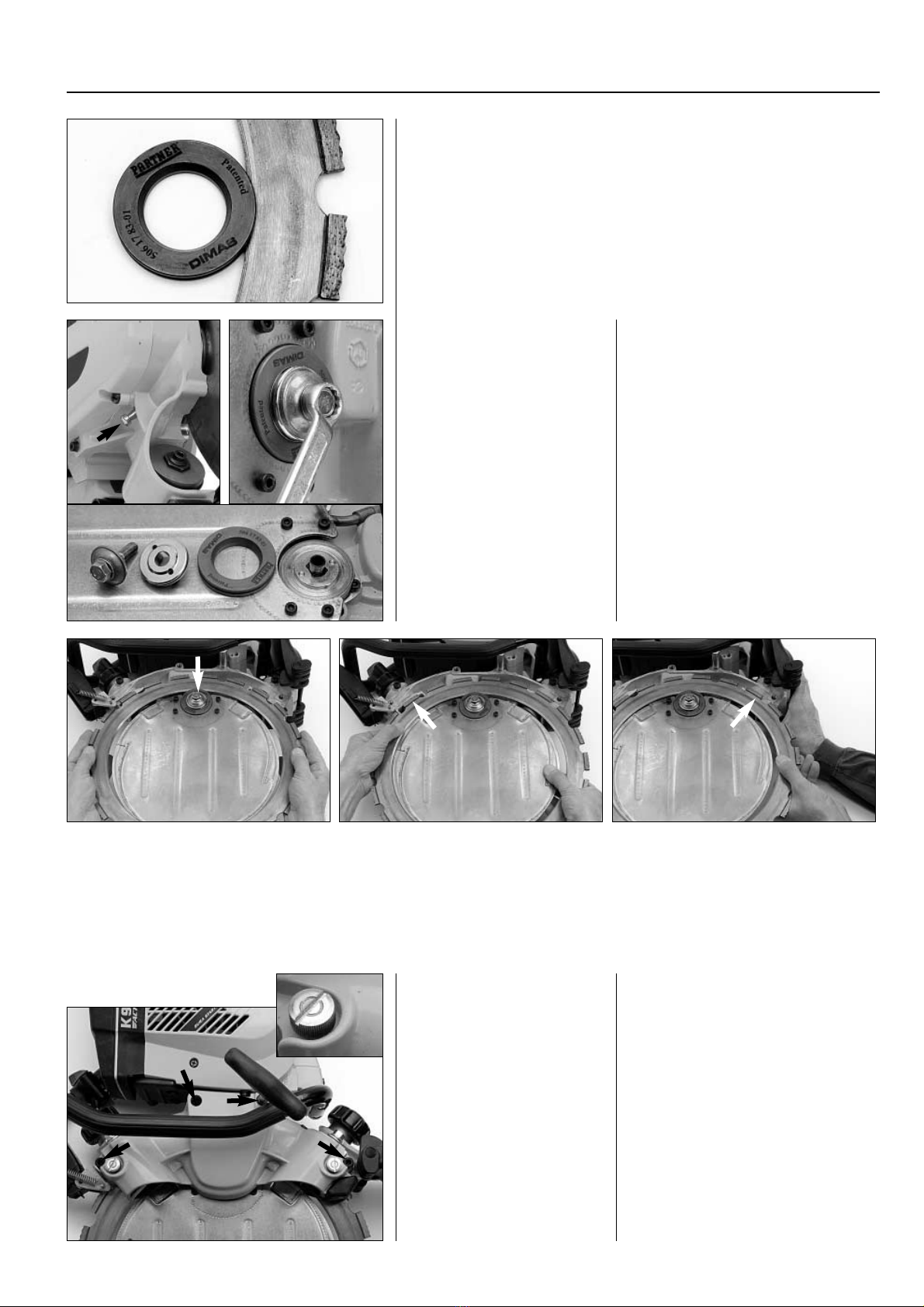

Adjustment

Important – knob unscrewed

Roller adjustment should always be

performed with the knob unscrewed

to its end position. Undo the lock-

nuts.

The best adjustment check is obtai-

ned if the lock-nuts are tightened

somewhat before adjustment is

carried out.

Rough adjustment

Rotate the blade by hand and tighten

the adjustment screws until the rol-

lers rotate.

Fine adjustment

Fine-tune the adjustment to a posi-

tion where you can easily stop the

rotation of the rollers using your

thumb (lower picture).

Tighten the lock-nuts – final check

Tighten the lock-nuts firmly and carry

out a final check of the adjustments.

Tighten the knob

End by tightening the knob that ten-

sions the blade against the drive disc.

Correct adjustment

Correctly adjusted rollers are very important to

the machine’s function and in order to reduce

wear.

Correct adjustment means that the rollers

should be in uniform contact with the blade

without any play or clearance.

If the rollers fit too tightly, the result is in-

creased wear and blade deformation, which

can even lead to blade breakage.

If the rollers are not fitted tightly enough,

the blade is not guided properly, which in the

worst-case scenario can lead to the blade jum-

ping out of its groove.

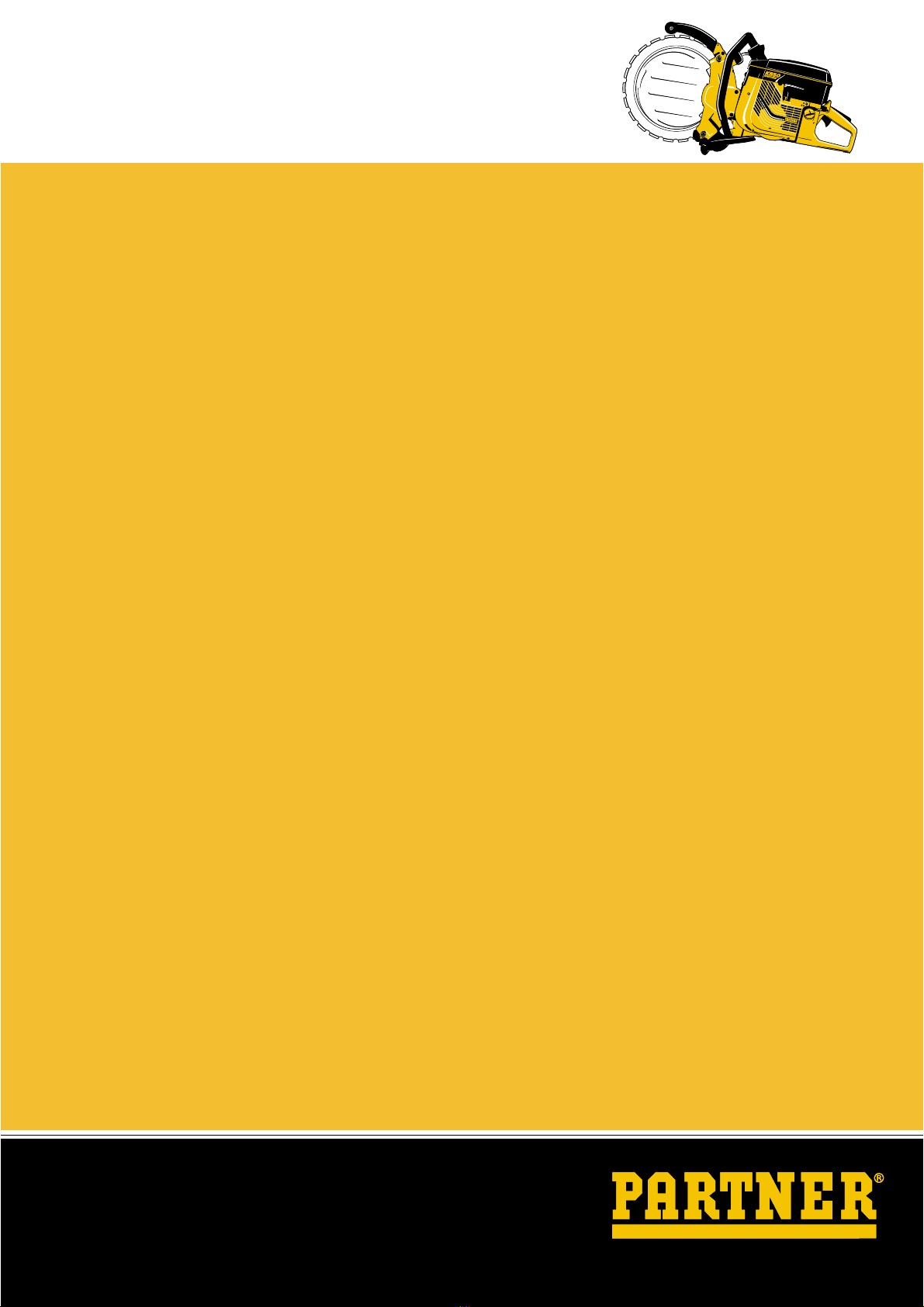

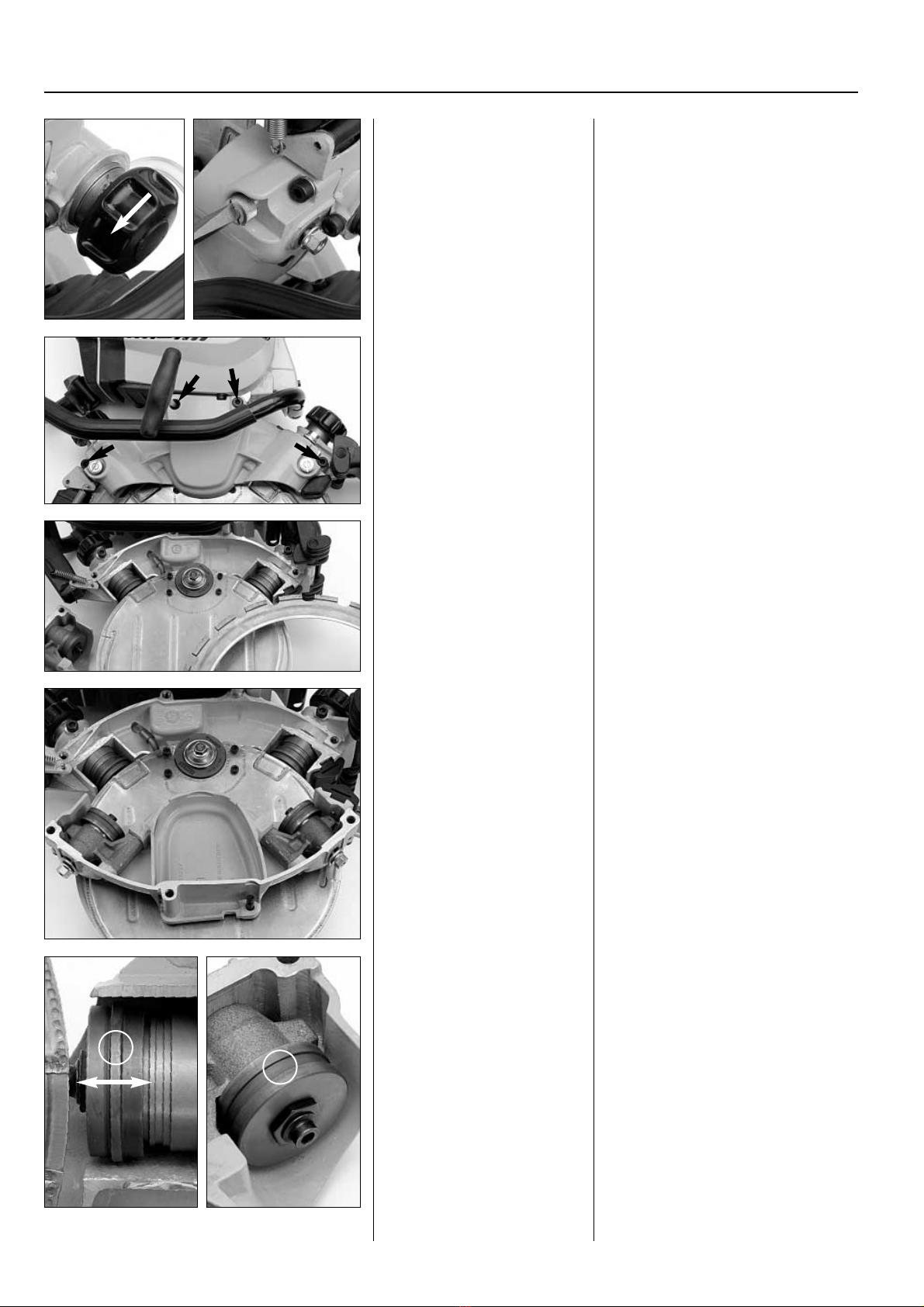

Function

The support rollers are fitted on levers in the

support roller shroud. The adjustment screws

(A) are used to alter the position of the lever.

The lock-nuts (B) lock the lever in position.

6

The rollers must always be adjusted when:

– switching to a new blade

– switching to another used blade

– replacing engagement or support rollers

Always check adjustment when the support roller shroud has

been removed and refitted.

A

A

A

AB

B

B

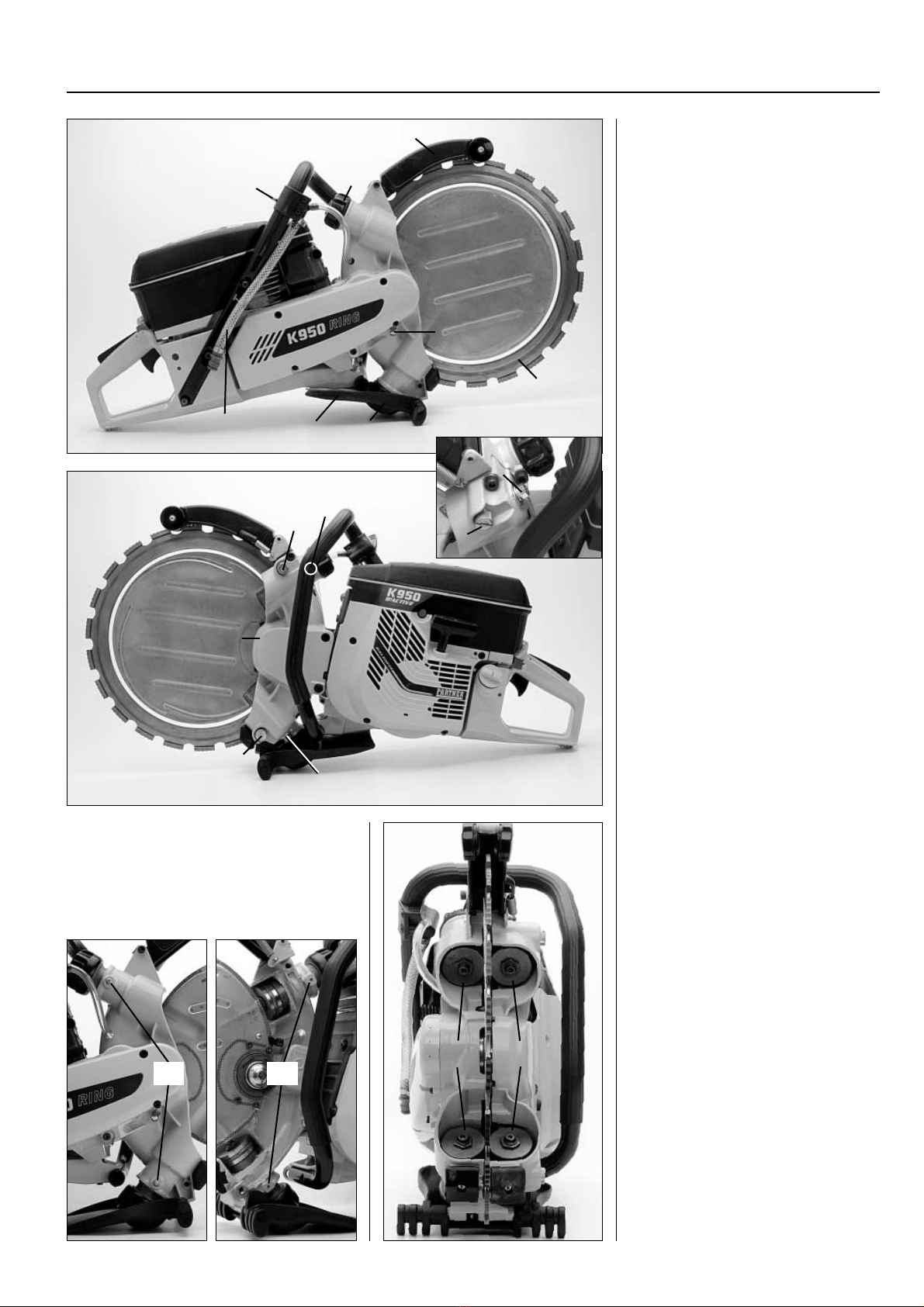

Inspection

At least once during the

blade’s lifetime

This check is carried out in

the same way as described

above.

Do not forget that the

knob must be unscrewed to

its end position when perfor-

ming the check!

Inspection

At least once during the blade’s

lifetime

This check is carried out in the same

way as described above.

Do not forget that the knob must

be unscrewed to its end position

when performing the check! If the

pressure is incorrect, undo the lock-

nut and adjust properly. Tighten the

lock-nut securely, carry out a final

check and end by tightening the

knob to its end position.