English –7

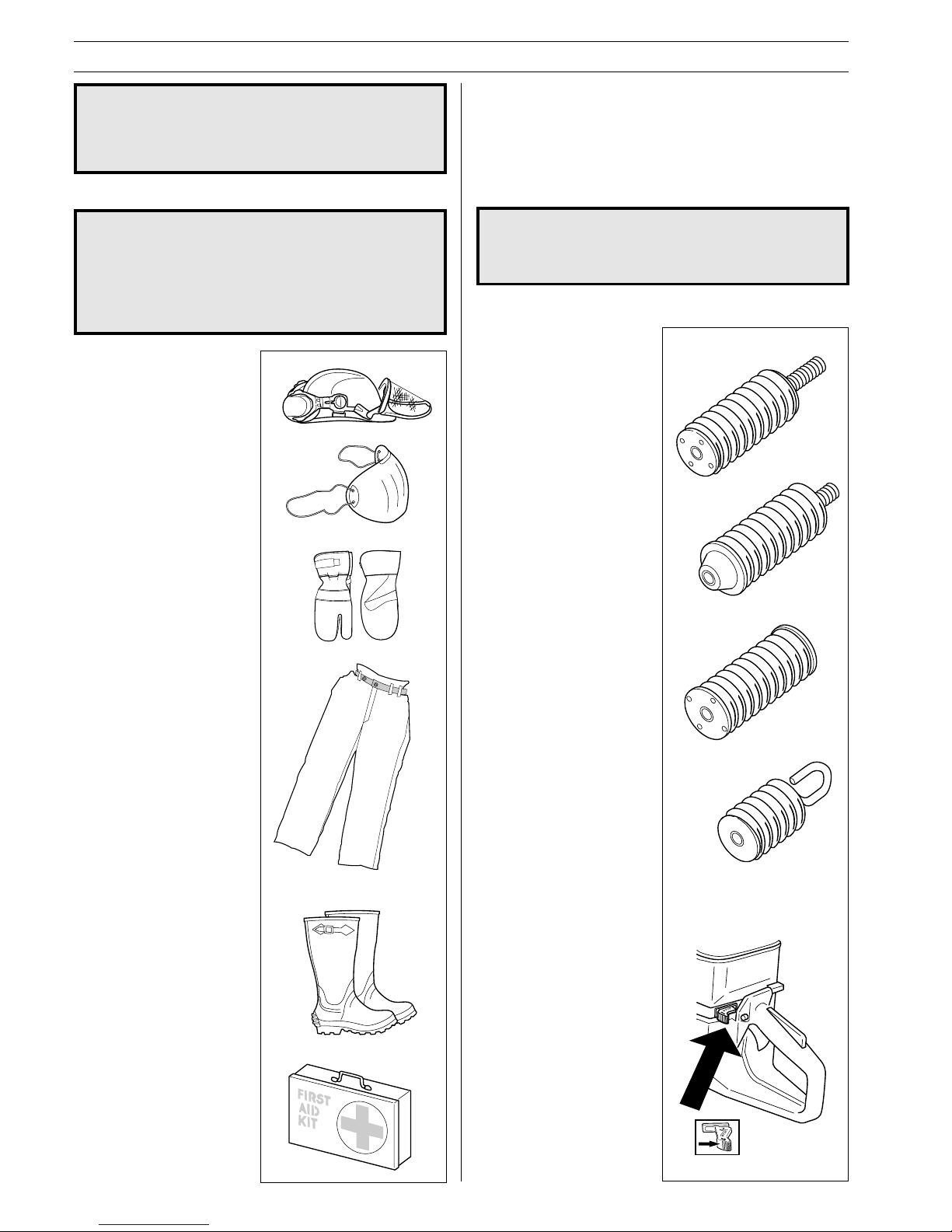

Fuel safety

(Filling/Fuel mixture/Storage)

WARNING! Exercise great care when handling

fuel. Bear in mind the risk of fire, explosions

and inhaling fumes.

•Never fill the machine while

the engine is running.

•Provide good ventilation

when filling or mixing fuel

(gasoline and 2-stroke oil).

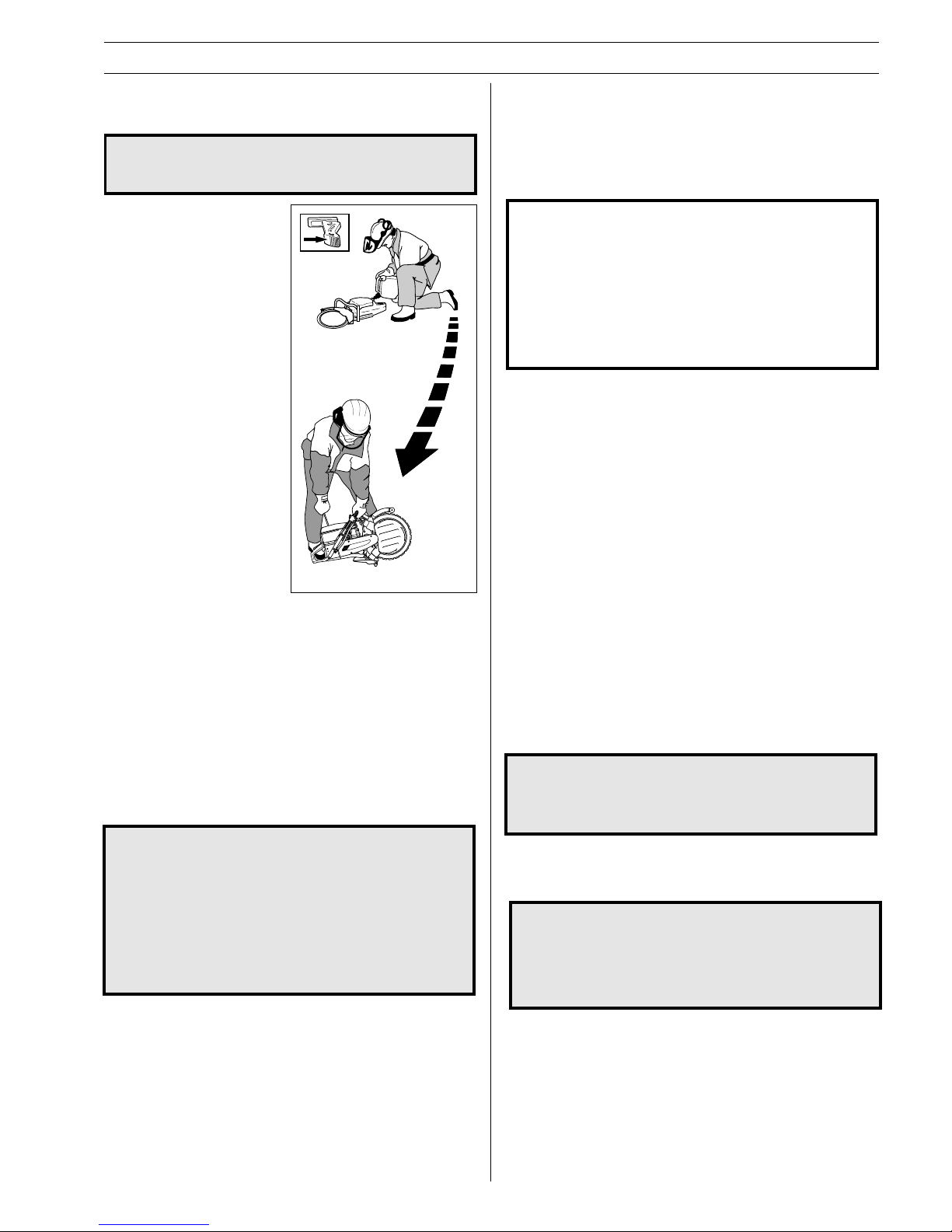

•Move the machine at least 3

m from the filling position

before starting.

•Never start the machine:

a) If you have spilt fuel

on it. Wipe up all

spillage.

b) If you have spilt fuel

on yourself or your

clothes. Change your

clothes.

c) If there is a fuel leak.

Make regular checks for

leakage from the fuel

cap and the fuel supply

pipes.

•Store the power cutter and fuel so that any leakage or fumes

do not risk coming into contact with sparks or naked flames.

For example, electric machines, electric motors, electrical

switches/power switches, heaters or the like.

•When storing fuel, approved containers intended for this

purpose must be used.

•When storing the power cutter for long periods the fuel tank

must be emptied. Contact your local fuel station to find out

how to dispose of excess fuel.

•Use a Partner fuel can with an anti-spill device.

SAFETY INSTRUCTIONS

!

!WARNING! Use a Partner fuel can with an

anti-spill device. Fuel and fuel fumes are

highly flammable. Think of the risks of fire,

explosion and breathing in fumes. Stop the

engine before refuelling. Do not overfill with

fuel. Mop up any spills on the ground or the

machine. If you spill fuel on yourself or your

clothes, change your clothes. Move the

machine at least 3 metres from the refuelling

site before starting.

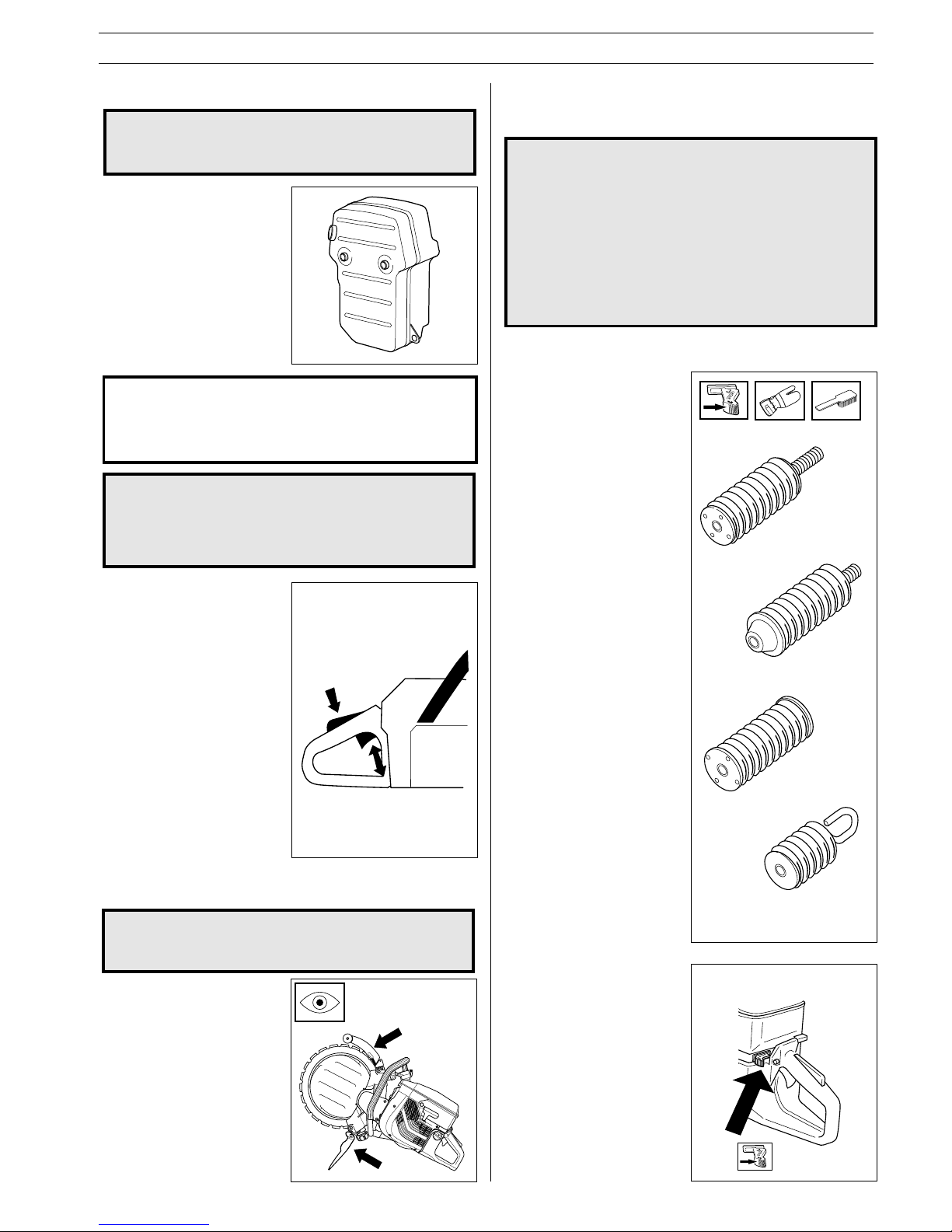

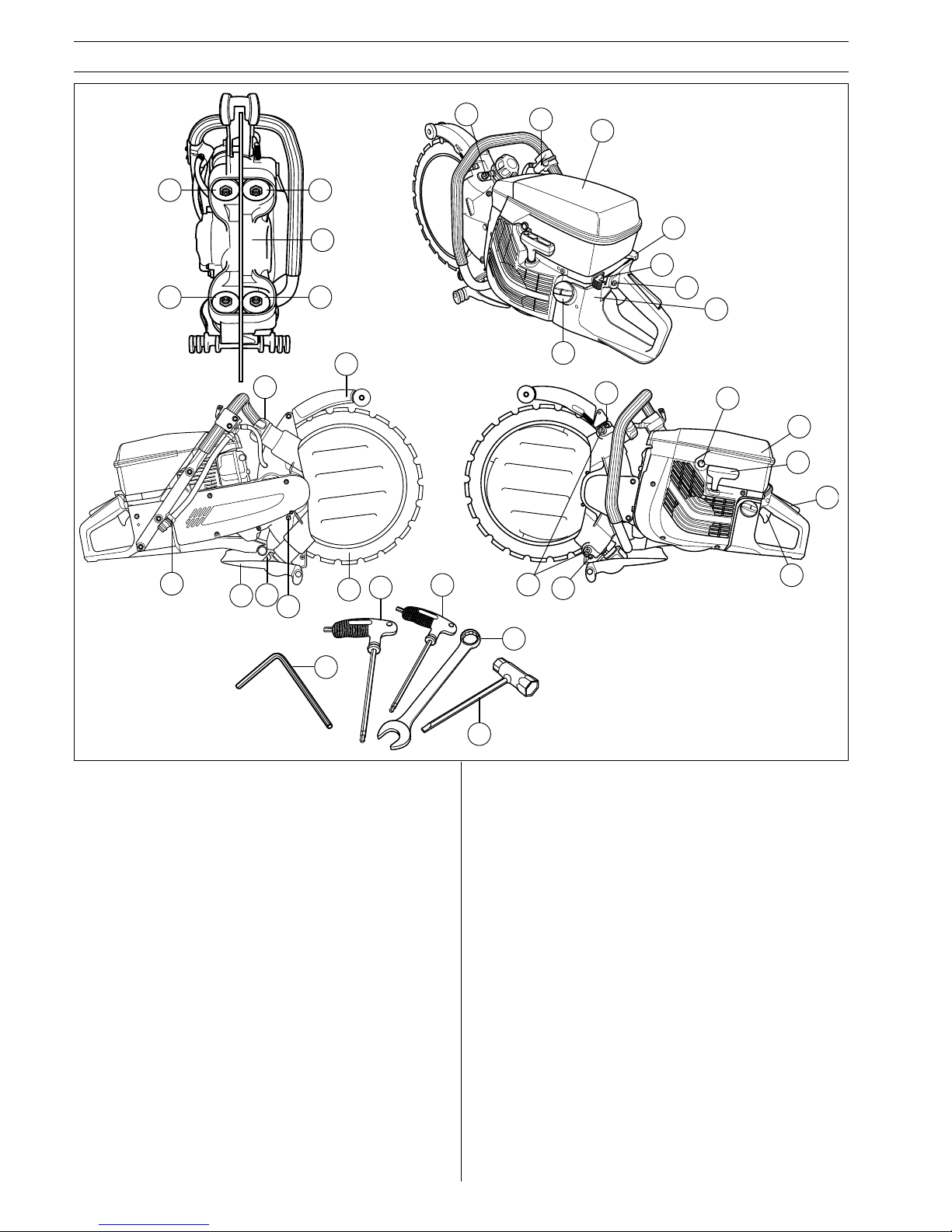

GENERAL WORKING INSTRUCTIONS

This section takes up the basic safety precautions for working

with the power cutter. Follow these general working instructions,

but never use a machine without the possibility of calling for

help in the event of an accident.

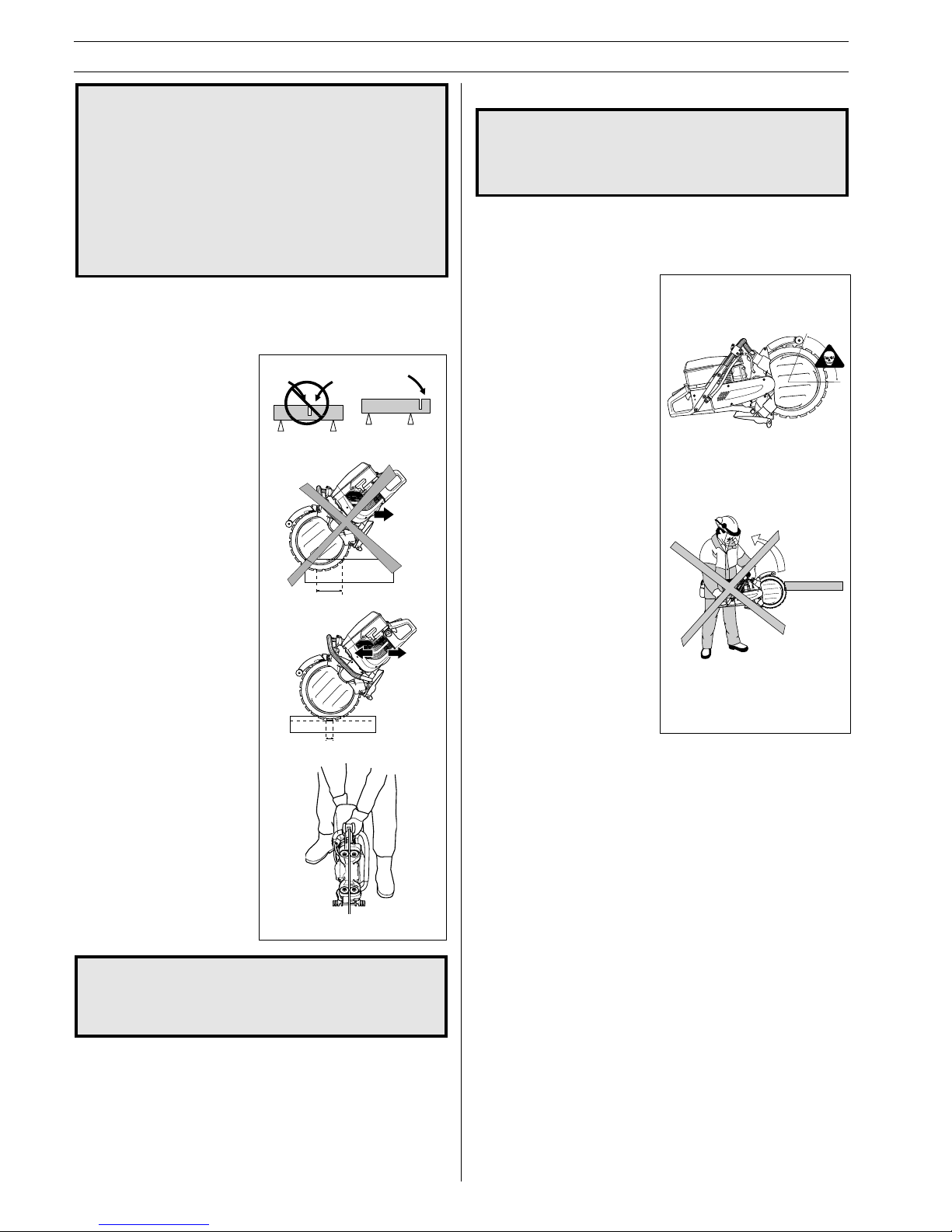

Basic safety precautions

IMPORTANT INFORMATION! Never work with a power

cutter that is defective or incorrectly adjusted. Do not

work with a power cutter that is incomplete or where

assembly has not been carried out in a satisfactory

manner. Check that the cutting blade stops rotating

when the throttle is released. If you encounter a situation

where you are uncertain how to proceed you should ask

an expert.

Avoid all usage which you consider to be beyond your

capability.

•Check that no one is in the immediate vicinity when the

machine is started or while working with the machine to

ensure that people, animals or other things cannot affect your

control of the power cutter.

•Avoid usage in unfavourable weather conditions, for example,

thick fog, heavy rain, strong winds or extreme cold, etc. To

work in bad weather conditions is tiring and can create

dangerous circumstances, e.g. slippery surfaces.

•Never start to work with the power cutter before the working

area is clear and you have a firm foothold. Look out for any

obstacles with unexpected movement. Ensure when cutting

that no material can become loose and fall, causing operating

injury.Take great care when working on sloping ground.

•Make sure clothing and parts of the body do not come into

contact with the cutting blade when the engine is started.

•Maintain a safe distance from the cutting blade when the

engine is running.

•The blade guard should always be fitted when the engine is

running.

•Ensure that the working area is sufficiently illuminated to

create a safe working environment.

•Do not move the power cutter with the blade rotating.

•Make sure that no pipes or electrical cables are routed in the

area to be cut.

WARNING! A safe distance from the power

cutter is 15 metres. You are responsible that

animals and onlookers are not in the working

area. Do not start to work with the power

cutter before the working area is clear and

you have a firm foothold.

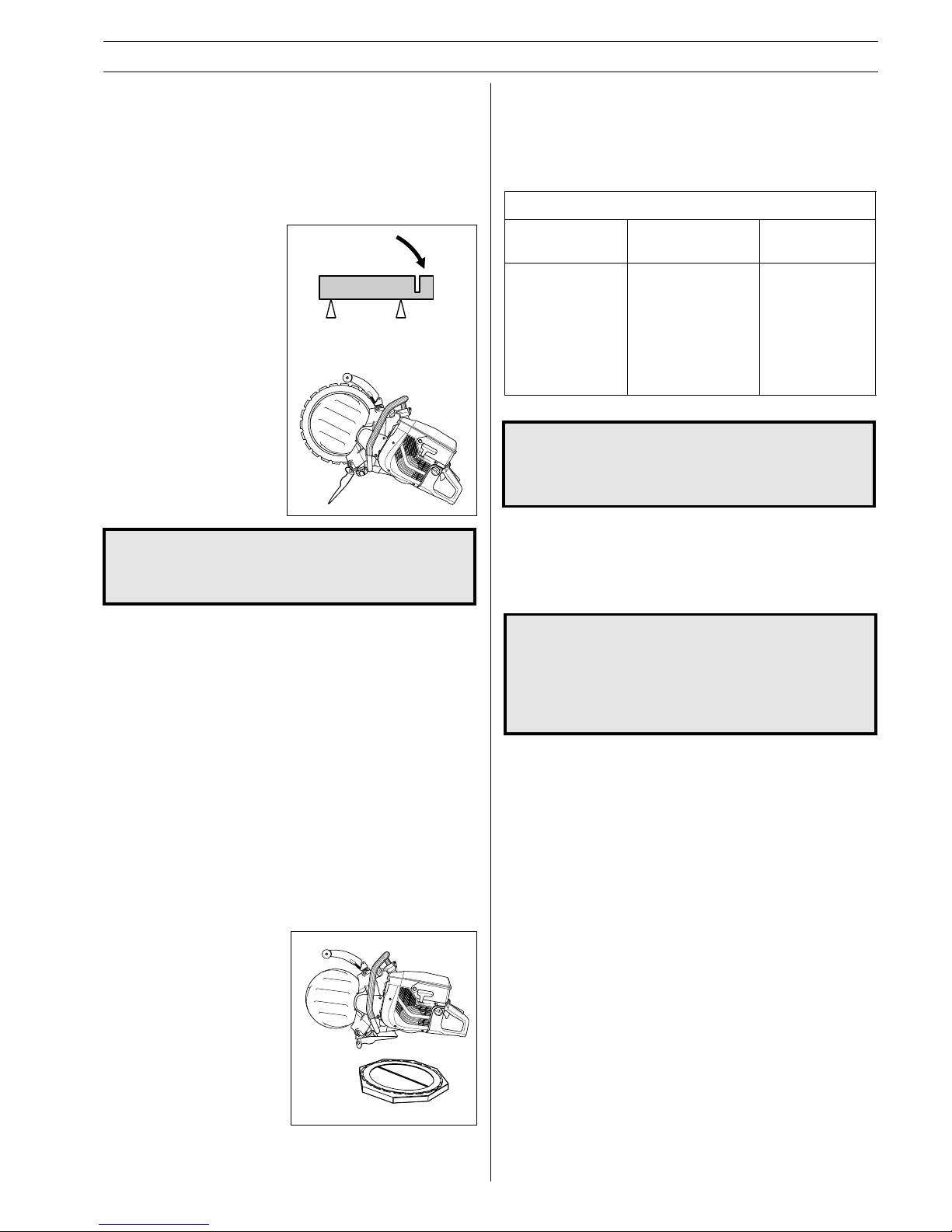

•Start cutting with the engine at full throttle.

•Always hold the power cutter firmly, with both hands. Hold

the machine so that the thumb and fingers grip around the

handle.

Cutting

Only use the machine in areas with good

ventilation. Neglect can result in serious

injury or death. Carbon monoxide in the

exhaust fumes causes suffocation.

!

!

Min 3 m (10ft)