012-03175E

4

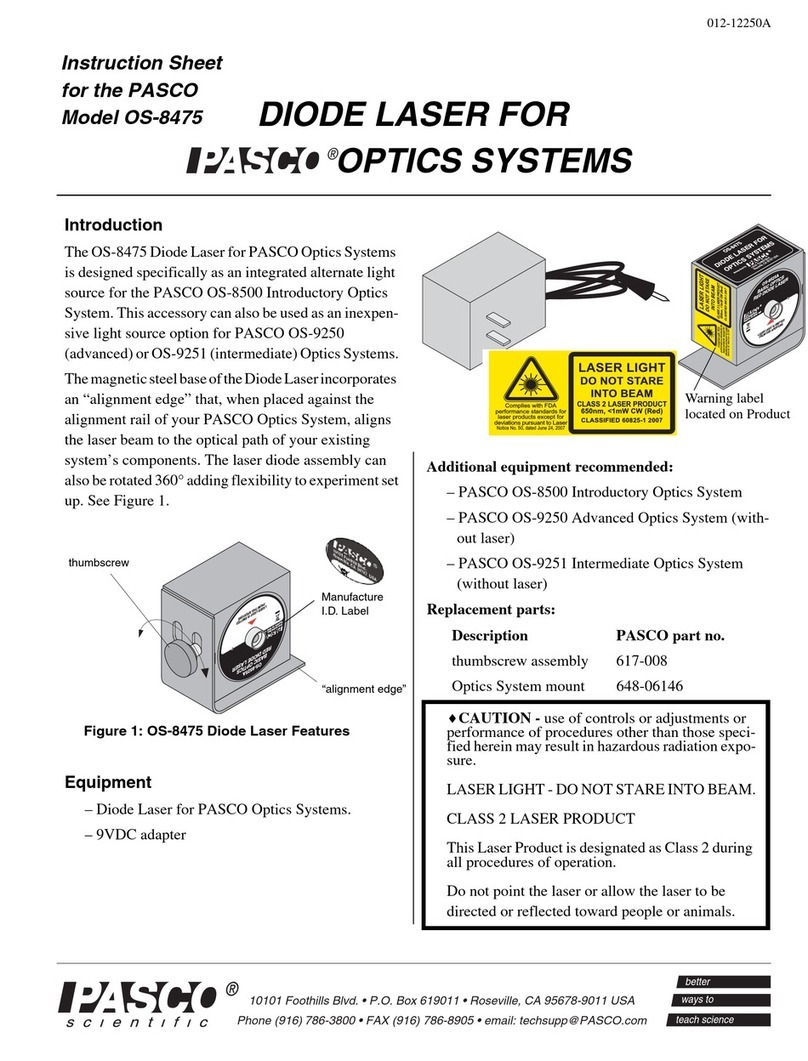

To measure the total capacitance:

①Turn on the Electrometer and zero the meter. Clip

the test lead of the probe to the inside cylinder of

your ice pail and the ground lead to the outside cyl-

inder (see Figure 4).

②Use a DC power supply or a statically charged ob-

ject to charge your proof plane.

③Place the proof plane inside the inner cylinder of the

ice pail and adjust the FUNCTION switch to get a

meter reading near full scale. (For convenience, you

may want to touch the proof plane to the inside of

the ice pail and then remove the proof plane. The

effect on the voltage reading should be negligible.)

Record the voltage as Ve. Do not discharge the

Electrometer.

④Take a capacitor of known capacitance, Ck. Ground

the leads of the capacitor to be sure it is fully dis-

charged, then connect the capacitor between the in-

ner and outer cylinder of the ice pail. With the

proof plane still inside the ice pail, record the meter

reading as Vk.

⑤The capacitance of the Electrometer, Ce, can now be

calculated as: Ce = CkVk/(Ve-Vk).

ä

EXPLANATION: This measurement is

shown schematically in Figure 3. First the

Electometer is charged with an unknown charge

Q, that must satisfy the equation Q = CeVe, where

Ceis the total capacitance of the system and Veis

the Electrometer reading. Then the second

capacitor is connected in parallel with the capaci-

tance of the Electrometer. The total capacitance

is now Ce+ Ck. The charge Q has not changed,

but now satisfies the equation Q =

(Ce+ Ck)Vk, where Vkis the new Electrometer

reading. Combining the two equations gives,

CeVe= (Ce+ Ck)Vk, or Ce= CkVk/(Ve -Vk).

If you want to use the Electrometer with a different set

of test leads, or a different ice pail, or even a different

proof plane, the capacitance may be different, and you

will need to repeat the above procedure to measure the

new capacitance.

ä

NOTE: The capacitance of the Electrometer

is 30-35 pf. With the test probe, the total capaci-

tance is approximately 150 pf. For best results,

measure the total capacitance.

Measuring Charge by Contact

Charges can also be measured by contact. You’ll find, for

example, that if you touch the charged proof plane to the

inside cylinder of the ice pail, the Electrometer reading will

generally remain relatively unchanged. This is because the

total capacitance is only negligibly affected by the proof

plane. This may not always be the case, however.

In general, contact measurements can be carried out in

much the same way as inductive measurements using

the ice pail. Touch the object with the test probe,

record the voltage V, and use Q = CV to calculate the

charge. However, if you suspect the object for which

you are measuring the charge appreciably affects the

total capacitance of the system, you will need to

remeasure the capacitance as described above.

Measuring Voltage

Voltage can be measured as with any voltmeter.

Connect the leads to the circuit, set the range (3, 10,

30, or 100 volts full scale), and read the voltage on the

meter.

Measuring Current

The Electrometer can be used for indirect current

measurements in many situations, though it is no

substitute for a good ammeter. Connect the Electrom-

eter leads across a known resistance in the circuit and

measure the voltage. Use Ohm’s law (Voltage =

Current x Resistance) to determine the current. The

effect of the Electrometer on the circuit will be negli-

gible in most circuits due to its exceedingly high input

impedance. However, the voltage drop across the

resistor must be within the voltage range of the Elec-

trometer.

If it is not convenient to hook the Electrometer across a

known resistance in the circuit, a precision resistor can

be connected between the input leads of the Electrom-

eter. The circuit can then be broken, as for connection

to a standard ammeter, and connected in series with the

precision resistor. Again, measure the voltage across

this resistor and calculate the current. (The problem

with this technique is that the resistance must be high

enough so the voltage drop is easily measured, but low

enough so it doesn't significantly affect the current

through the circuit.)

Using a Projection Meter

The OUTPUT connectors on the ES-9054B Electrom-

eter provide an output signal for driving a projection

meter, oscilloscope, or other monitoring device. The

output is proportional to meter deflection (within 10%)

with a

±3.6 VDC output corresponding to a full scale deflec-

tion. (The OUTPUT voltage depends only on meter

deflection. It is independent of the range setting of the

FUNCTION switch.)