CALCAL

PC RCPC RC

GAUSSGAUSS

D PD P

R

RR

aa

RRRRRR

zz

qq

tt

¡À¡À

20um20um

¡À¡À

40um40um 80um80um

¡À

umum

uinuin

2.5mm2.5mm

0.8mm0.8mm

0.25mm0.25mm

3.19

3.20

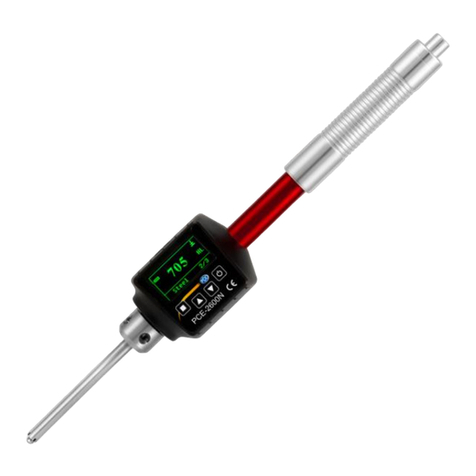

Fig. 3.5

3.23

3.21

3.22

3.24

3.25

3.26

3.19 Filter

3.20 Calibration

3.21 Measurement

3.22 Position pointer

3.23 Browsing

3.24 Memory

3.25 Parameters

3.26 Battery

3.3installation and unloading of sensor

Toinstall, hold the main part of the sensor by hand,

push it into connection sheath at the bottom of the

pull it out.

a.The probe of the sensor is the main part of this

instrument and requires close attention

not be touched in order to avoid damage which can

affect measurement results.

c. Connection of the sensor should be reliable during

installation.

b. During installation and unloading, the probe should

of sensor or the root of protective sheath andslowly

push to the end ofsheath. To unload, hold the main part

5

3.29

3.28

3.27

3.27 Unit

3.28 Cutoff

3.29 Ranges

instrument as shown in Figure 3.4 and then slightly

8

Length, please see the table in 10.7on page 15.

E. To check if the profile filter selected is right. if not,

or key.

F. To check if the measurement unit selected is right.

To switch between the metric system and the

British system. To quit, just press the any key other

than key or key.

G. To clear the surface of the part to be measured;

H. Refer to Figure 3.7 and Figure 3.8 to place the

surface to be measured. Adjust

I. Refer to Figure 3.8: the sliding trail of the sensor

must be vertical to the direction of process line of the

measured surface.

J. Adjustable leg and sheath of sensor

Instrument correctly, stable and reliably on the

the bottom surface of the instrument, the sheath of sensor

complete measurement (as shown in 3.9).

if not, depressing the key and not releasing it till

starting depressing key . and then pressing or

'UNIT' on the Display. It takes about 8 seconds from

and not releasing it till 'FILT'

on the Display . It takes about 4 seconds from starting

Depressing . and then pressing key or key

to cycle between RC,PC-RC,Gauss,D-P or vice

versa. To quit, just press the any key other than key

depressing the

and adjustable leg can be used for auxiliary support to

When the measured surface of the part is smaller than

DEL

MENU

DEL

MENU

READ

SAVE

SAVE

READ

READ

READ

DEL

MENU

DEL

MENU

SAVE

SAVE

After preparations is done, just press Start key to measure

probe stop sliding and move backward. The measurement

result shows on the display after the probe stop moving.

4.2 Measuring

4.2.1 Save the measurement results to the tester for

later use

4.2.2 How to browse the different parameters

In state, you can browse different parameters.

The corresponding parameter and its value show on

the display once depressing the key

4.2.3 Delete the measurement results

to automatically. On the other hand, the new

measurement results will replace the old ones if

pressing the Start key in state.

5.HOW TO BROWSE THE MEMORIZED DATA

No matter in state or state, you can browse

the memorized data by depressing the key . The

browsing state is marked in on display. When in

the key or key . The serial number of the group

depressing the key . Then the symbol changes

state, you can browse different groups by depressing

10

After measuring, you will see the original becomes

the key .

Then the symbol M changes to M

if measuring conditions are not to be changed. Firstly,

you will see the on the display and the probe is

moving forward and sampling. Then you will see the

the M . in such a state, you can save this group of

results including Ra,Rz,Rq,Rt and measurement

conditions to the memory of the tester by depressing

automatically while the number of memorized groups

increases 1.

In state, you can delete this group of results by

SAVE

RaRz...

DEL

MENU

READ

READ

SAVE

MM

M

R

R

M

M

M

M

M

---

7

measurement, preparations have to be made and checked.

to select.For the recommended cutoff

4.MEASURING PROCEDURES

4.1 Preparations for measurement

A. Switch onto test ifthe battery voltageis normal.

B. The instrument automatically restores conditions

of the lastmeasurement before it is turned off since

these conditions are automatically stored.

Meanwhile, the secondline of 2 digits on display

C. To check ifthe range selectedis right. ifnot,

depress the key to select.

D. To check ifthe cutoff length selected isright. if not,

shows the groups stored in the memory. Before taking

depress the key

Part while charging.

B. The meanings of battery indicators are:

Indicates normal voltage and measurement can be

carried out;

should be charged as soon as possible;

A. Layout of connection lines shouldn t affect measuring

The black part inside prompt shows capacity of

Battery; Indicates too-low voltage and battery

charging so that it is not necessary to turn it off. The

indicates that batteryis full.

C. Relative highnoises of thepower source canaffect

measurement to weaksignal to someextent when

battery is being charged;

D. The instrument needs to monitor the process of

instrument will turnon automatically evenwhen

switched off.

RANGE

CUTOFF