AMC-103

4 PEAKTRONICS

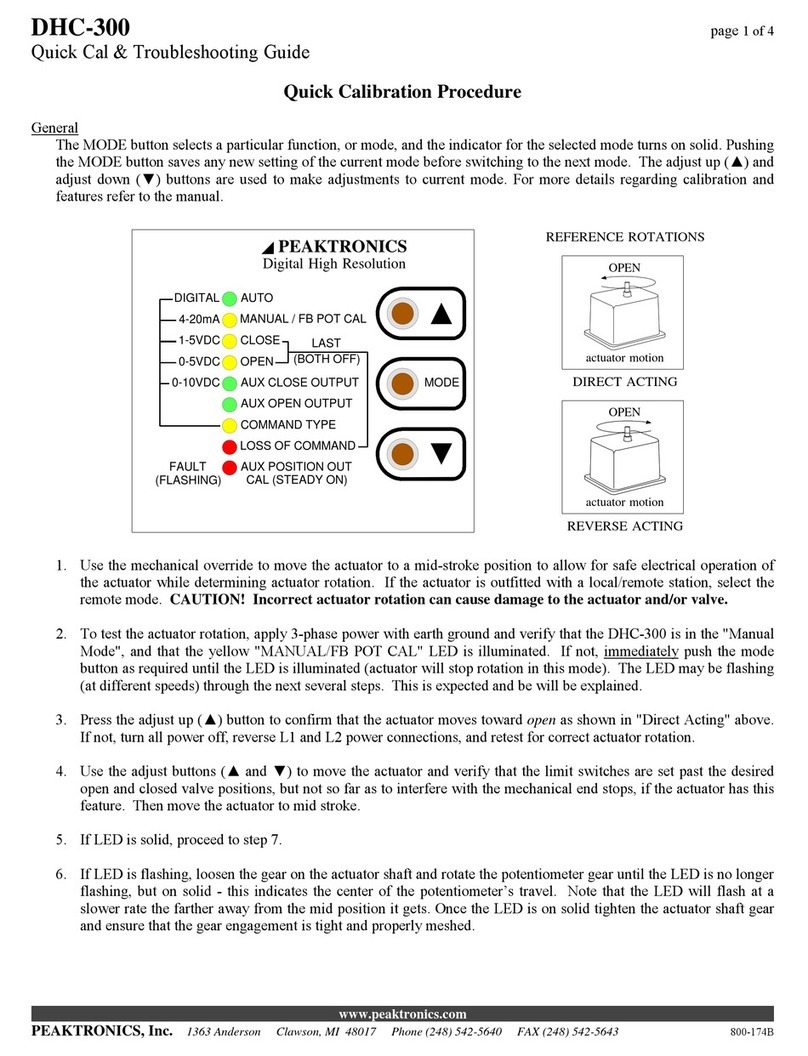

POWER

Power is connected to the terminals marked LINE

and NEUTRAL. The unit does not have an earth ground

connection; earth ground should be connected to the body

of the actuator. The fuse installed on the unit is rated for

maximum output current that can be safely delivered by

the AC outputs. Replacement fuses must not exceed the

maximum rating of 2.5A in order to prevent damage to the

unit. Smaller fuse sizes can be used with smaller motors -

consult the actuator manufacturer for appropriate fuse size

and type.

MOTOR and FEEDBACK POT

The actuator motor and feedback potentiometer are

connected as shown in the block diagram. The OPEN ter-

minal should be connected to the motor winding that moves

the actuator toward the open position, and conversely, the

CLOSED terminal is connected to the winding that moves

the actuator toward the closed position. The COMMON

terminal is the neutral or common wire to the motor wind-

ings. The AMC-103 is suitable for powering most dynamic

brakes used with electric actuators; however, consult the

actuator manufacturer for more information.

The feedback potentiometer wiper must be con-

nected to the WIPER terminal. One end of the potenti-

ometer is connected to the +5V OUT terminal, and the oth-

er is connected to the GND terminal. The potentiometer

should be connected so that when the actuator moves to-

wards the open position, the potentiometer's resistance be-

tween the WIPER and GND terminals will increase. This

can also be measured as a voltage - the voltage between the

WIPER and GND terminals should increase when the actu-

ator moves towards the open position. If the potentiometer

is wired incorrectly, the typical response of the unit will be

to run the actuator to the full open or closed position, re-

gardless of the command signal input, and the correspond-

ing output indicator remains on.

The feedback potentiometer should be mounted to

provide a proper feedback signal through the entire range

between the open and closed positions. For best results,

position the actuator to the midway point between the open

and closed positions; then adjust the feedback potentiome-

ter for approximately 2.5 VDC (or 1/2 of the potenti-

ometer's resistance) between the WIPER and GND termi-

nals.

Since the feedback potentiometer is crucial for

proper operation of the AMC-103, the following items

should be carefully observed:

1 - Potentiometer resistance should be a value from

1K to 10K ohms.

2 - The potentiometer should be a linear taper type.

3 - The potentiometer must be properly wired to pro-

vide the correct feedback signal.

4 - The potentiometer must be properly and securely

mounted in order to provide a reliable feedback

signal.

COMMAND SIGNAL

An appropriate command signal, either 0-5V, 0-

10V, 4-20mA, or 1-5V, should be connected to the appro-

priate terminal (as shown in the Block Diagram) while

using the SIGNAL GND terminal as the return signal

ground. The AMC-103 must be configured for the type of

command signal that is to be used. Jumper plugs JP1 and

JP2 should be properly installed (as shown in the Outline)

prior to operating the unit.

+12V OUT

The +12V OUT terminal provides an auxiliary

+12VDC output that can be used to power a command

input 4-20mA transmitter, or a position feedback transmit-

ter (either 4-20mA or 0-5/10V). Note that only one

transmitter can be powered by the AMC-103. When pow-

ering a 4-20mA transmitter with the +12V OUT, care

should be taken to insure that the total resistance of all

devices connected in the 4-20mA loop does not exceed

300 ohms. See Wiring Diagrams for various applications.

OUTPUT INDICATORS

The AMC-103 has on-board indicators that identi-

fy when one of the motor outputs is turned on. When the

open output is turned on, the red LED indicator will turn

on, and when the close output is turned on the green LED

indicator will turn on (see Outline).

Many actuators are equipped with limit switches

at the open and closed positions that are intended to dis-

connect power to the motor to prevent mechanical dam-

age. For this reason, it is possible that the AMC-103 will

indicate that one of the motor outputs is turned on when

the actuator is not in motion. However, it should be noted

that when the indicator is on, power is applied to the mo-

tor output.