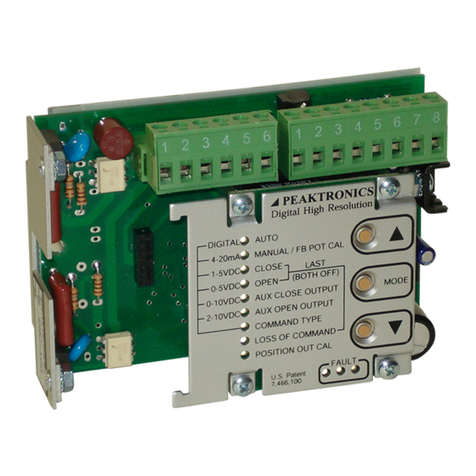

DHC-100

6 U.S. Patent 7,466,100 applies to this product PEAKTRONICS

Upon selecting the CLOSE function, the DHC-

100 will begin moving the actuator to the previously set

closed position; it is not necessary to make an adjustment

if the unit has been previously set to the desired position.

A command signal input of 0V, 1V, 2V, 4mA, or 0% au-

tomatically corresponds to the defined closed position.

OPEN

The OPEN function works the same way as the

CLOSE function with the exception that the adjust buttons

are used to set the desired open position. As with the

CLOSE function, upon selecting the OPEN function, the

actuator will move to the previously set open position.

Once the desired position is set, the DHC-100 will auto-

matically correspond a command signal input of 10V, 5V,

20mA, or 100% to the open position.

AUX CLOSE OUTPUT

The AUX CLOSE OUTPUT function is used to

set an optional output setting that is associated with the

closed position - an appropriate relay option module is

required to use this output. The adjust buttons are used to

set the actuator to a desired position. Whenever the actua-

tor position falls between the defined closed position and

the Aux Close position, the Aux Close Output indicator

will flash. Additionally, the DHC-100 will turn on a relay

output on the optional relay module - the output can be

used to drive an alarm or merely act as an auxiliary limit

switch.

Upon selecting the AUX CLOSE OUTPUT func-

tion, the DHC-100 will begin moving the actuator to the

previously set position. It is not necessary to make an ad-

justment if the unit has been previously set to the desired

position.

AUX OPEN OUTPUT

The AUX OPEN OUTPUT function is used to set

an optional output setting that is associated with the open

position - an appropriate relay option module is required

to use this output. The adjust buttons are used to set the

actuator to a desired position. Whenever the actuator po-

sition falls between the defined open position and the Aux

Open position, the Aux Open Output indicator will flash.

Additionally, the DHC-100 will turn on a relay output on

the optional relay module - the output can be used to drive

an alarm or merely act as an auxiliary limit switch.

Upon selecting the AUX OPEN OUTPUT func-

tion, the DHC-100 will begin moving the actuator to the

previously set position. It is not necessary to make an ad-

justment if the unit has been previously set to the desired

position.

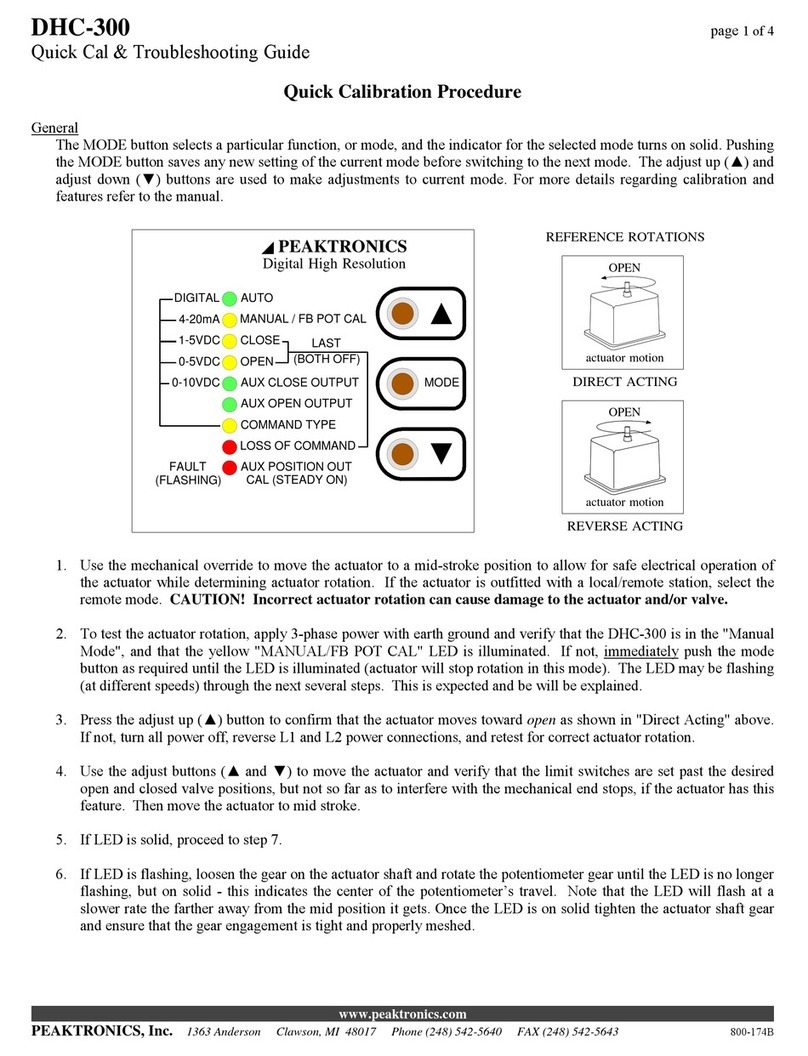

COMMAND TYPE

The COMMAND TYPE function is used to con-

figure the command signal input for either 4-20mA, 1-5V,

0-5V, 0-10V, 2-10V, or Digital so as to match the type of

command signal being used. Upon selecting the COM-

MAND TYPE function, the Command Type indicator will

turn on steady, while the indicator for the selected type

will flash. Use the adjust buttons (▲ or ▼) to select the

desired input type. The selection will be saved when the

MODE button is pressed, which will also advance the unit

to the LOSS OF COMMAND function.

LOSS OF COMMAND

When using 1-5V, 2-10V, 4-20mA, or a Digital

input type for the command signal, the DHC-100 will de-

tect when the command signal is lost or out of range. A

loss of command condition is detected whenever the input

is disconnected, the input becomes less than 0.75V (for 1-

5V input), 1.5V (for 2-10V input) or 3mA, or the input is

connected backwards. An out of range condition is de-

tected whenever the input becomes greater than 5.25V (for

1-5V input), 10.5V (for 2-10V ipnut), or 21mA. If the

DHC-100 detects a loss of the command, a fault will be

indicated (see FAULT INDICATORS), and the actuator

will be moved to one of three preset positions: the open

position, the closed position, or the position last attained

prior to losing the command signal. The LOSS OF

COMMAND function is used to set the desired default

position.

When the LOSS OF COMMAND function is se-

lected, the adjust buttons are used to set the default posi-

tion. The DHC-100 indicates the selected default setting

by flashing the Open function indicator for the open de-

fault position, or it will flash the Close function indicator

for the closed default position. When neither indicator is

on, then the "last position" default is selected.

When a 0-5V or 0-10V command signal is used, a

loss of command signal cannot be reliably detected.

Therefore, if the unit is configured for a 0-5V or 0-10V

command signal (see COMMAND TYPE), the MODE

button will not select the LOSS OF COMMAND function.

However, the DHC-100 can detect when a 0-5V or 0-10V

command signal is out of range (i.e., greater than 5.25V or

greater than 10.5V) or connected backwards. When an

out of range condition is detected for a 0-5V or 0-10V in-

put, the motor is turned off (leaving the actuator in its "last