TUNING THE BOTTOM SNARE.

The bottom snare wire should be fixed securely in place between the snare strainer lever and the butt end by either snare

cords or plastic ties.

The snare wires should be positioned so that when they are raised up to the bottom head, they sit in a central position

between the snare bed / rim of the drum.

Please ensure that the top snare is in the off position.

1. Raise the bottom snare lever so that the snare wires are raised against the snare head.

2. Turn the adjusting thumbscrew on the snare lever to raise (clockwise) or lower (anti-clockwise) the snare wires until the

desired sound is reached (by tapping the drum with a stick when making adjustments, you should be able to hear the

change in snare sound until the required sound is reached). The thumbscrew also stretches the snare wire across the

snare head and caution should be taken to not over tension the snare wires. This will not only cause damage to the

snare wires but also affect the tone of the drum (A large percentage of time, a dull tone or an over- ring on the drum is

caused by under/over tensioning the snare heads and wires)

CHECK FREQUENTLY THAT THE HEAD IS EVENLY TENSIONED BY LOOKING ACROSS THE COUNTER HOOP.

ANY DISCREPANCIES WILL BE INDICATED BY THE HOOP BEING DISTORTED. THIS IS RECTIFIED BY ADJUST-

ING THE ROD TENSION AT THE POINT WHERE THE HOOP IS DISTORTED.

SIDE DRUM - INTERNAL & EXTERNAL SNARE MODEL

TENSIONING & TUNING

TENSIONING THE TOP (BATTER) HEAD

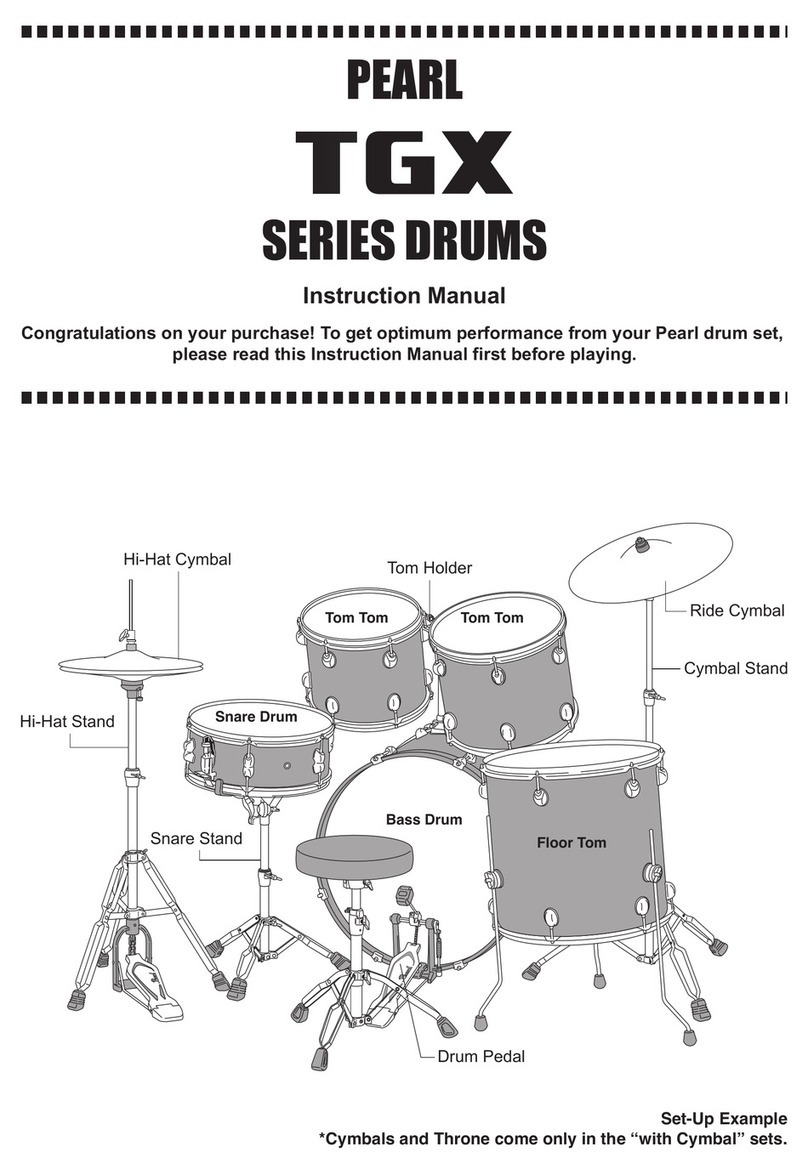

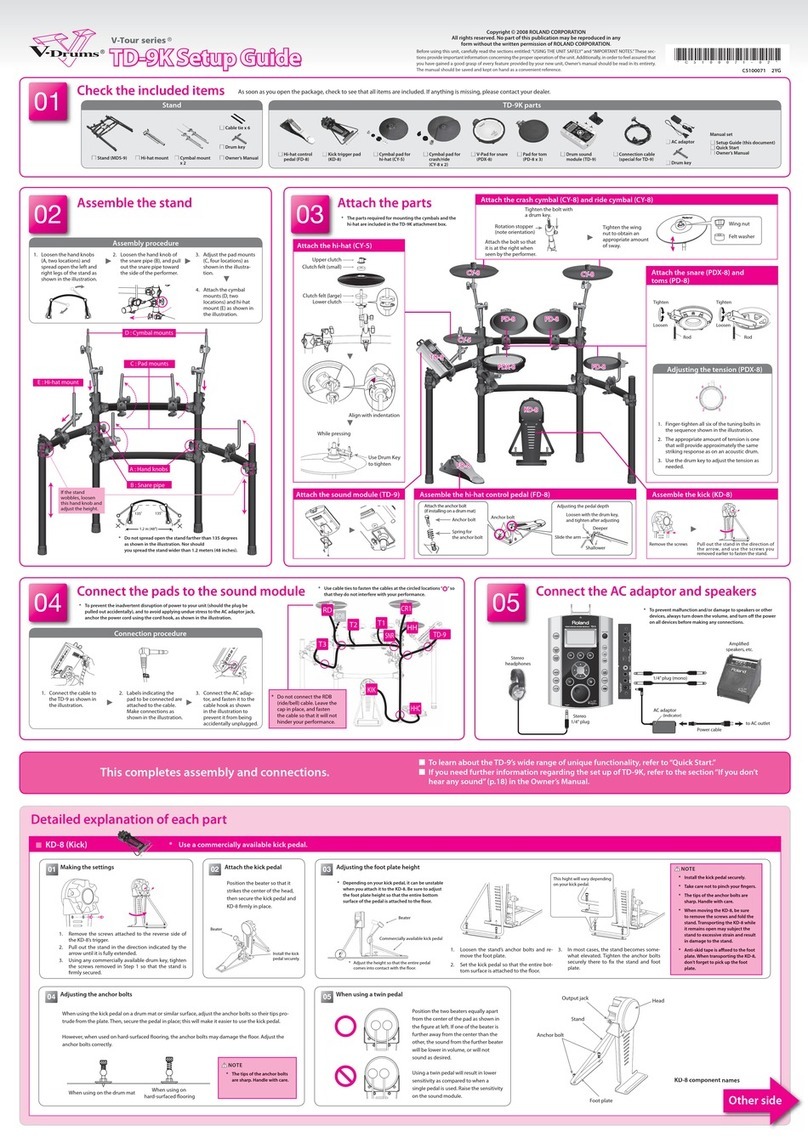

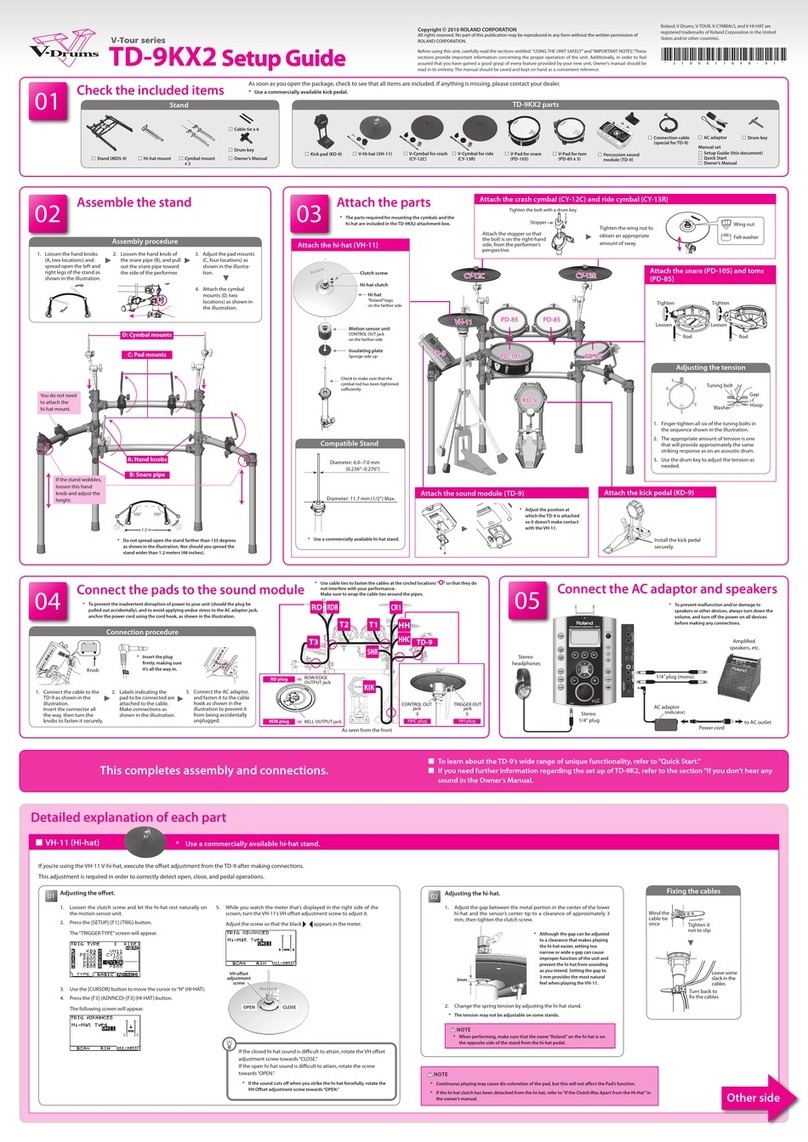

1. Place the drum (the right way up) on a stand, hard surface or preferably wear it in the playing position.

2. Make sure the snares are set to the OFF position.

3. Number the tension bolts 1 to 8.

4. There are no specific guide lines for how tight the top head needs to be as this is down to the individual player to

decide depending on how high or low they want their drum to be pitched. If the top head is at the required tension then

please move to the secion ‘tuning the snares’, if not move to step 5.

5. Starting at tension bolt number 1. Using the drum key provided, turn the tension bolt clockwise, a ¼ of a turn.

6. Repeat step at tension bolt number 5

7. Repeat step at tension bolt number 6

8. Repeat step at tension bolt number 2

9. Repeat step at tension bolt number 3

10. Repeat step at tension bolt number 7

11. Repeat step at tension bolt number 8

12. Repeat step at tension bolt number 4

13. Repeat steps 4 to 11 until the required tension is reached. By tapping the drum at each stage, you should be able to

hear the pitch of the drum getting higher as the bolts are tightened.

Warning

Under no circumstances should these Viscount drums be tensioned too high.

Over tensioning will invalidate any manufacturer’s or suppliers’ guarantees.

You are still entitled to your statutory rights under the Sale of Goods Act 1979.