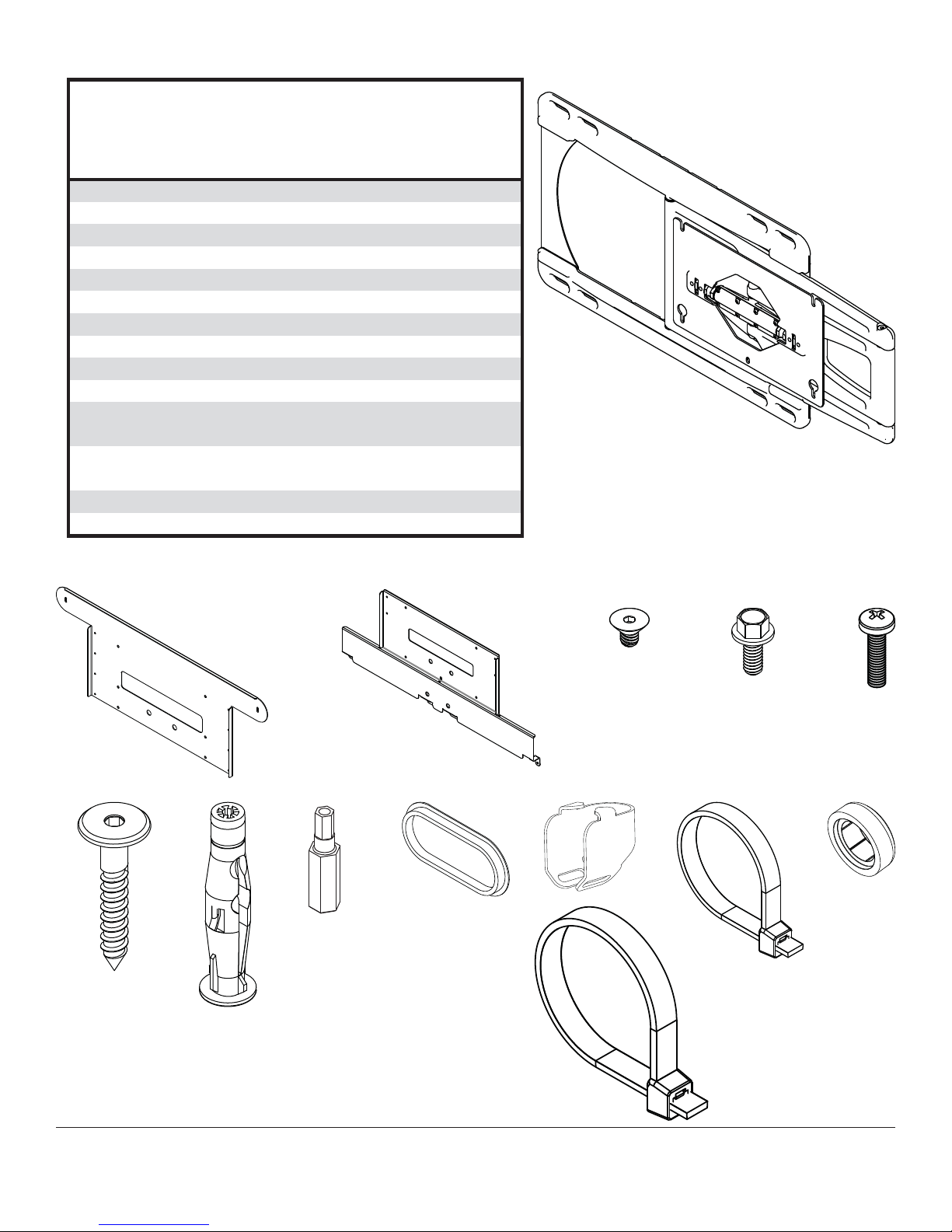

5 of 11 ISSUED: 10-01-10 SHEET #: 095-9354-1

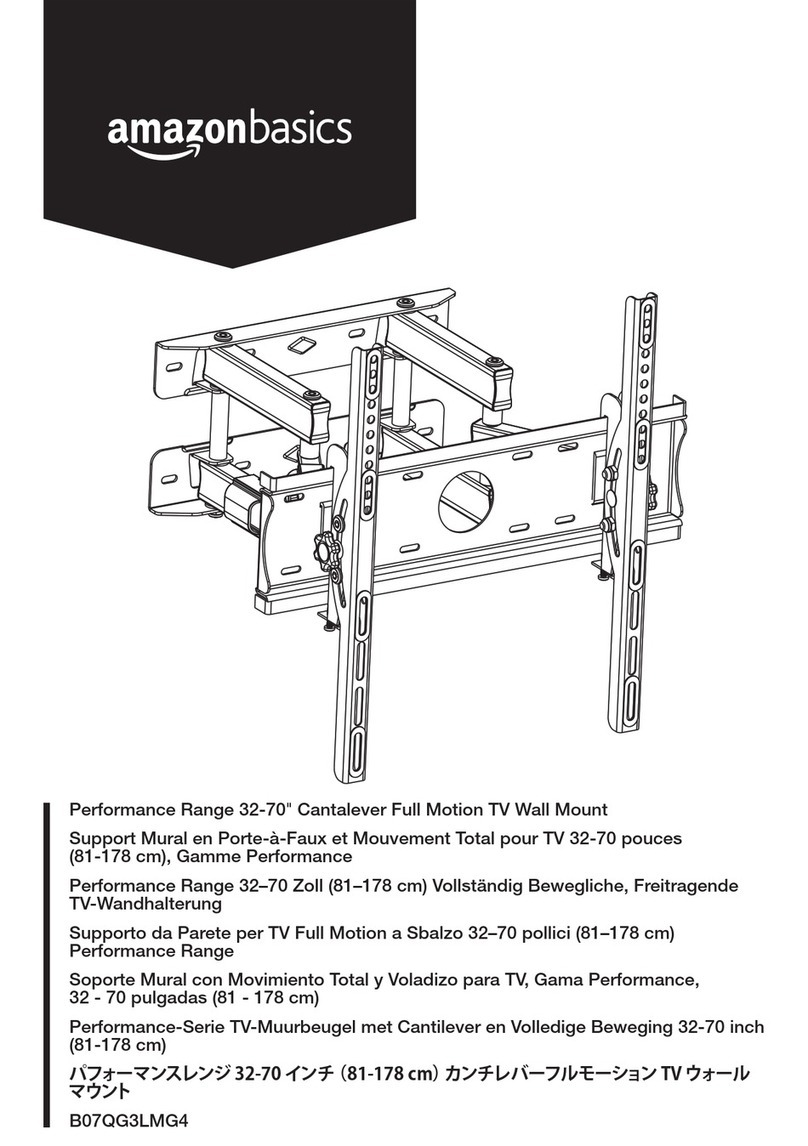

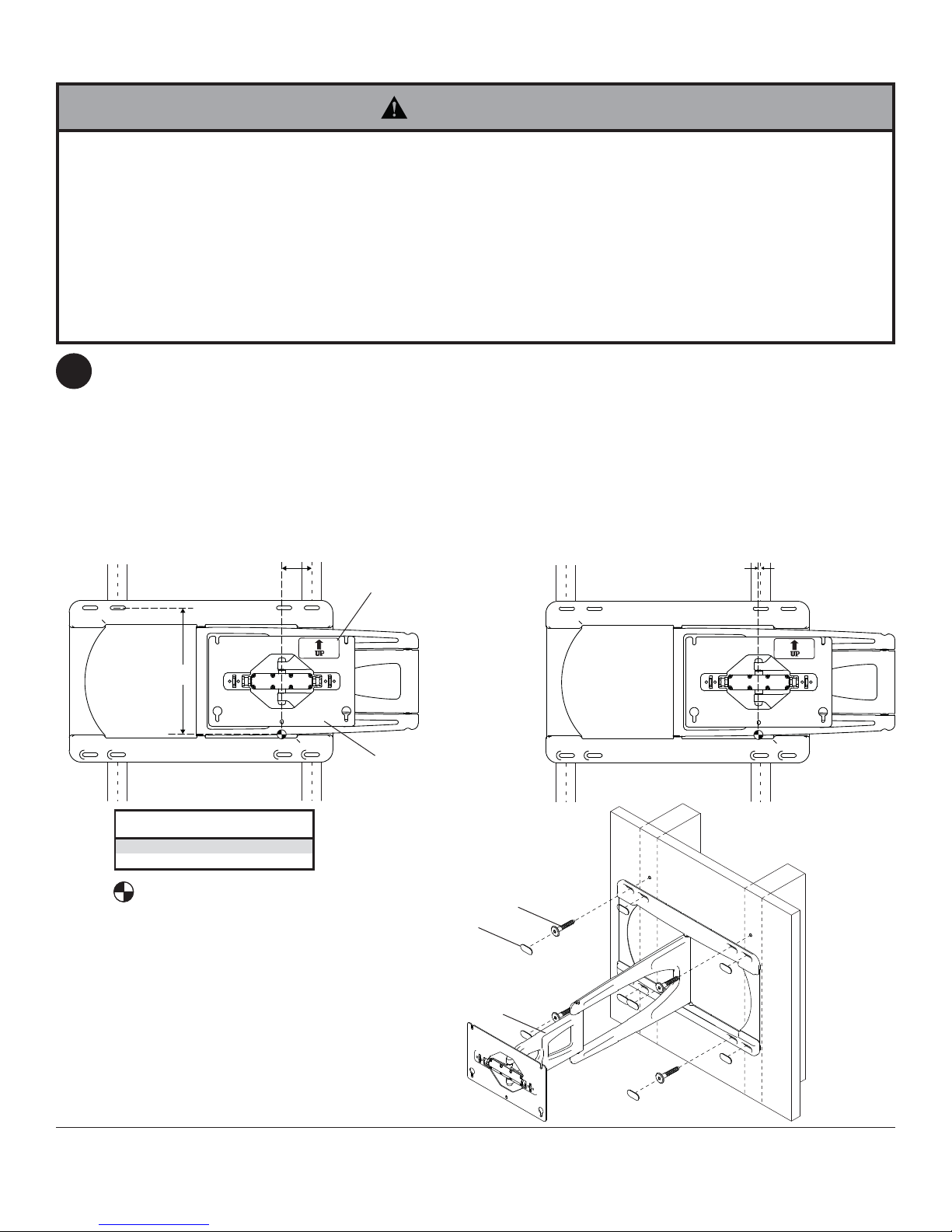

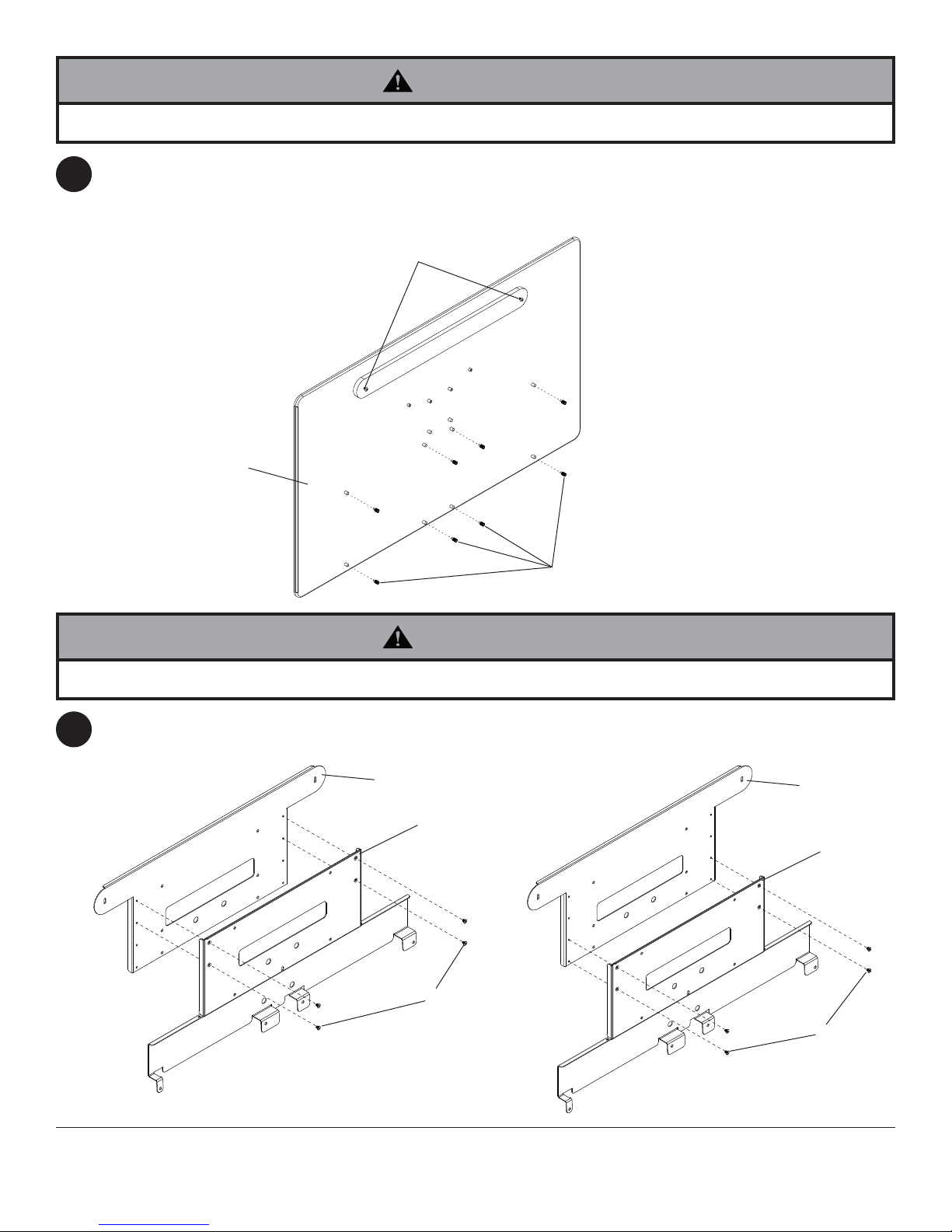

Installation to Solid Concrete or Cinder Block

NOTE: Wall arm assembly (A) must be mounted to

wall using inner mounting holes.

Make sure that wall arm assembly is level and use

wall plate as a template to mark four mounting holes.

Top mounting slot will be X" above the screen center

as shown in figure 1.1 and chart 1 on page 4. Drill four

5/16" (8 mm) dia. holes to a minimum depth of 2.5"

(64 mm). Insert anchors (E) in holes flush with wall as

shown. Place wall arm assembly over anchors and

secure with wood screws (D). Level, then tighten all

fasteners. Insert eight fastener caps (G) into mounting

holes.

NOTE: Be sure arrow of label is pointing up when

mounting wall arm assembly (A) to wall as shown in

figure 1.1.

SOLID CONCRETE

CINDER BLOCK

1

• When installing Peerless wall mounts on cinder block, verify that you have a minimum of 1-3/8" (35 mm) of actual

concrete thickness in the hole to be used for the concrete anchors. Do not drill into mortar joints! Be sure to mount

in a solid part of the block, generally 1" (25 mm) minimum from the side of the block. Cinder block must meet ASTM

C-90 specifications. It is suggested that a standard electric drill on slow setting is used to drill the hole instead of a

hammer drill to avoid breaking out the back of the hole when entering a void or cavity.

• Concrete must be 2000 psi density minimum. Lighter density concrete may not hold concrete anchor.

• Installer must verify that the supporting surface will safely support the combined load of the equipment and all at-

tached hardware and components.

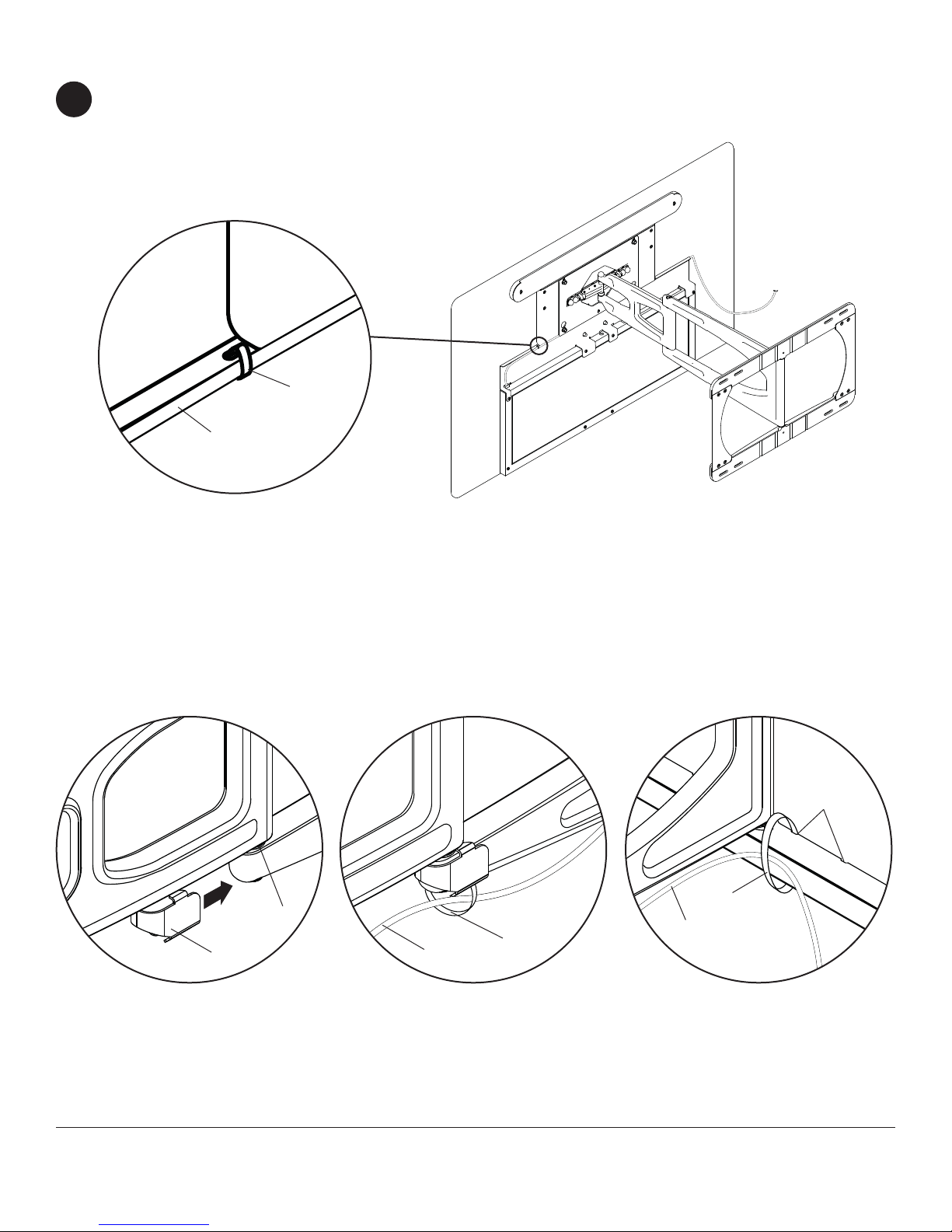

WARNING

• Tighten screws so that wall plate is firmly attached,

but do not overtighten. Overtightening can damage

screws, greatly reducing their holding power.

• Never tighten in excess of 80 in. • lb (9 N.M.).

• Always attach concrete anchors directly to load-

bearing concrete.

• Never attach concrete anchors to concrete covered

with plaster, drywall, or other finishing material.

If mounting to concrete surfaces covered with a

finishing surface is unavoidable (not evaluated by

UL), the finishing surface must be counterbored

as shown below. Be sure concrete anchors do not

pull away from concrete when tightening screws. If

plaster/drywall is thicker than 5/8" (16 mm), custom

fasteners must be supplied by installer (not evaluated

by UL).

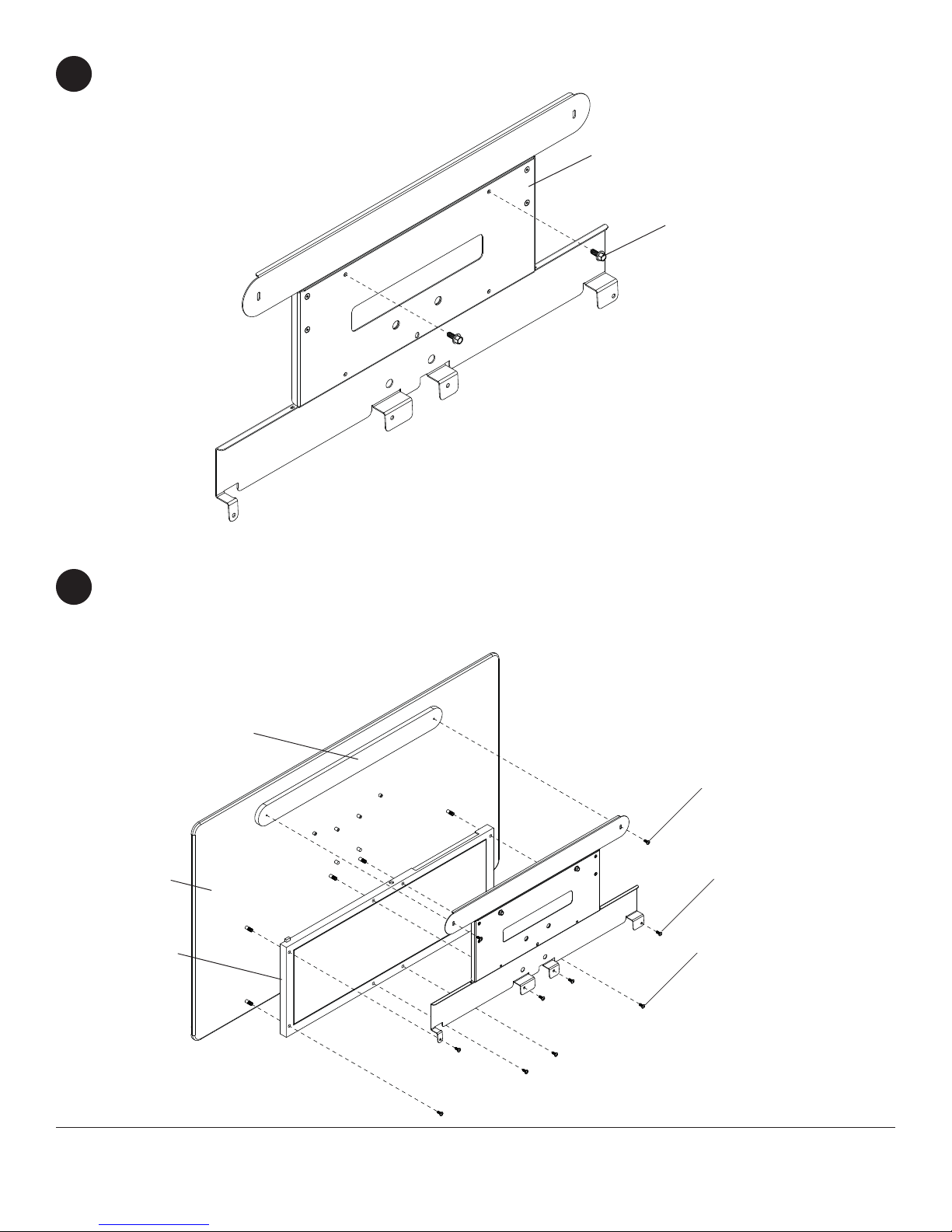

WARNING

CUTAWAY VIEW

INCORRECT CORRECT

wall

plate

wall

plate

plaster/

drywall

plaster/

drywall

concrete concrete

1

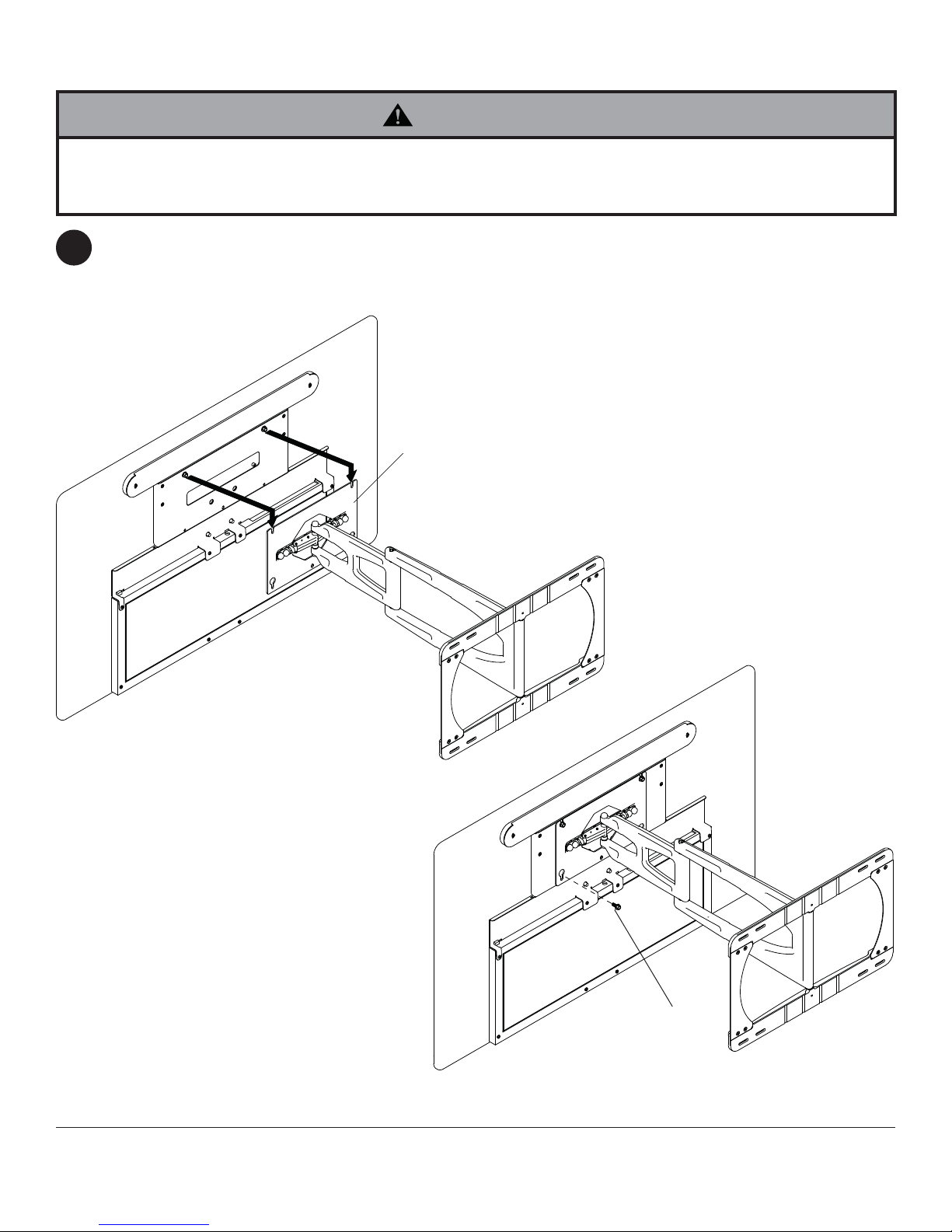

3

2

E

Drill holes and insert anchors (E).

Place plate (A) over anchors (E) and secure with screws (D).

Tighten all fasteners.

A

F

E

D

concrete

surface

A

G

D

E