EN-TraceTekTT1100OHP-IM-H5826301/15

THERMAL BUILDING &

INDUSTRIAL HEAT TRACING SOLUTIONS

1 / 8

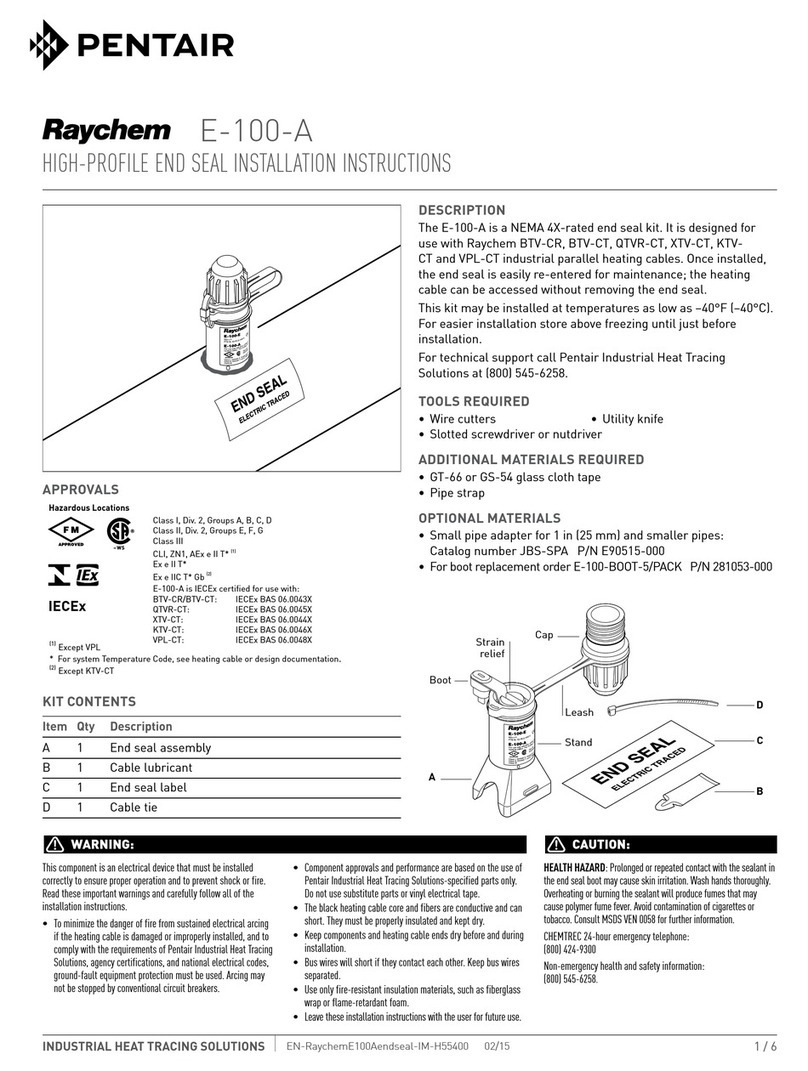

DESCRIPTION

These Instructions explain the proper procedures for installing and

testing TraceTek TT1100-OHP sensing cables. TT1100-OHP sensing

cables are primarily intended for use on overhead piping to detect a water

leak originating from a small pin hole or crack in the pipe. The wicking

action of the absorptive synthetic fiber outerbraid on the TT1100-OHP

cable can catch and hold a small drip or trickle of water– to ensure

sufficient wetted length to generate a leak alarm. TT1100-OHP can also

be used on floors, in drip pans, in sumps and trenches and similar flat

surface applications, however TT1000 standard water detection cable may

be better suited to flat surfaces.

Important Notes

When used to monitor suspended or rack mounted pipe, TT1100-OHP

sensing cables must be attached to the pipe at the lowest point where

any water leak is most likely to drip from the pipe system. This will be the

6 o’clock position on horizontal piping but other mounting locations and

techniques may be necessary if site conditions are unusual. In particular,

special consideration should be given to pipe supports, couplings, “T’s”,

valves and other fittings. It is the responsibility of the installer to position

the cable such that any leak will drip onto the cable.

The sensor cable cannot stop a leak. In some installations the materials

or structures beneath the pipe system may be so critical or valuable,

that a drip tray system should be considered in addition to the sensor

cable installation. TT1100-OHP is intended to alert the user that a pipe or

system is leaking but it cannot prevent collateral damage if the leak is not

contained and repaired immediately.

GENERAL NOTES: DO’S AND DON’TS:

TOOLS REQUIRED

Wire cutters Used to cut off tie wrap ends

TT-PTB-1000

(PN 486437-000)

Portable Test Box, battery powered instrument

designed for testing and troubleshooting TraceTek

systems

Digital multimeter Can be used as an alternative or supplement to the

PTB. Meter must have 20 MΩ range

TT-MAPPING CAP-PC

(PN P000000872)

Used to simulate leaks at connector points during

commissioning and mapping process

Extra TT-MLC-PC

(PN 683262-000)

Leader cable. Used with the ohmmeter to make

easier connections to the sensor cable for resistance

measurements

Extra TT-MET-PC

(PN 169905-000)

End termination. Used during installation or trouble

shooting to temporarily isolate a sub-section of sen-

sor cable for resistance measurements

ADDITIONAL MATERIALS REQUIRED

Tie wraps Supplied by installer and sized to go around the pipe

and sensor cable. Base quantity on one tie wrap per

foot (0.3 m) for horizontal run with extra wraps at

fittings.

Rags and appropriate

cleaner

Use to wipe and clean bottom and side surfaces of

pipe prior to cable installation.

OPTIONAL MATERIALS

TT-MBC-PC

(PN 847529-000)

Branch connector used to connect and branch "T"

lines

TT-MJC-xx-PC This jumper cable is available in various pre-cut and

terminated lengths

TT-1100-OHP-CK-PC-M/F

(PN P000001186)

Connector kit used during field connections of

TT1100-OHP bulk cable

DO:

•Storethecableinitsoriginalcontainerinaclean,dryareauntilreadytoinstall.

•Cleanthepipesurfacewherethecablewillbeinstalled.

•Schedulethesensorcableinstallationaslateaspossibleintheconstructionscheduletoavoidrisk

ofdamageorcontaminationbyothercontractorsorconstructiontasks.

•Removecablefromthepipeifanythreadcutting,welding,solderingorsimilarpipefittingworkwill

beperformed.

DON’T:

•Dragthecablethroughwater,paint,solvents,oilorothercontaminants.

•Installdamagedorcontaminatedsensingcable.

•Allowthecabletobecomewetorcontaminatedafterinstallation.

•Exceedthemaximumpullingforceof100kg(220lb).

•Usethecableasaropeforliftingorsecuringanyobject.

•Allowtoolsorheavyobjectstofalloncable.

•Exceed3300ft(1000m)sensorcablecircuitlength

TT1100-OHP

Water SenSing Cable for SuSpended pipe inStallation inStruCtionS

TRACETEK