1 / 14

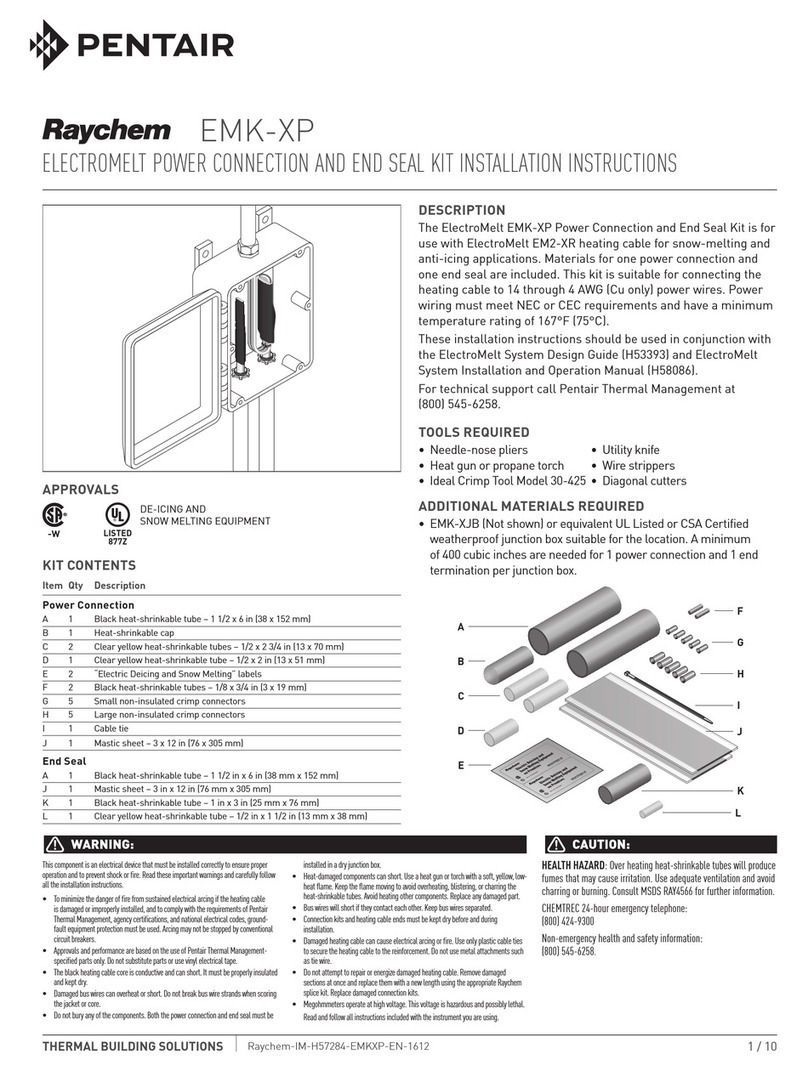

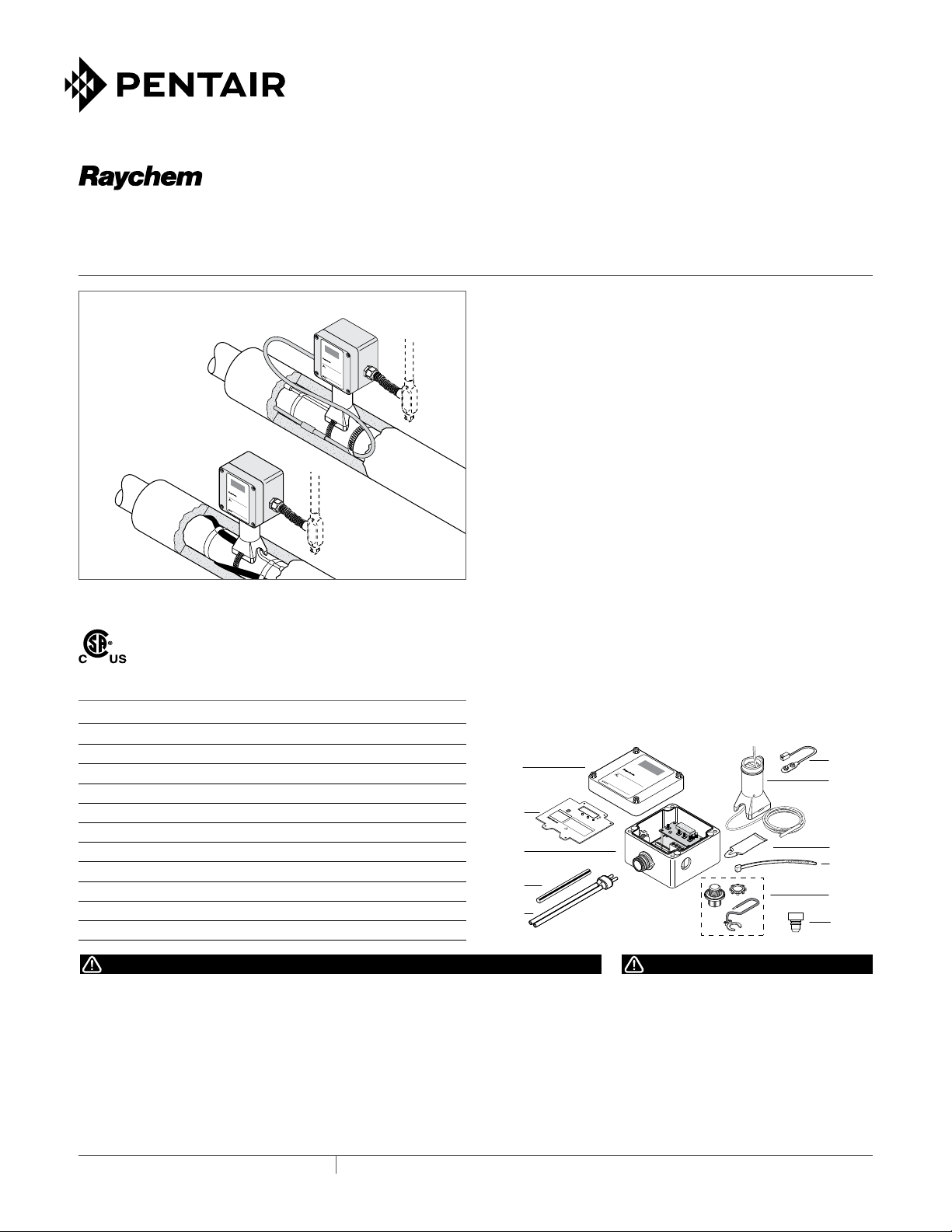

JBS-100-ECP-A

Combination power ConneCtion box and digital eleCtroniC Controller

installation instruCtions

INDUSTRIAL HEAT TRACING SOLUTIONS EN-RaychemJBS100ECPA-IM-H5746305/16

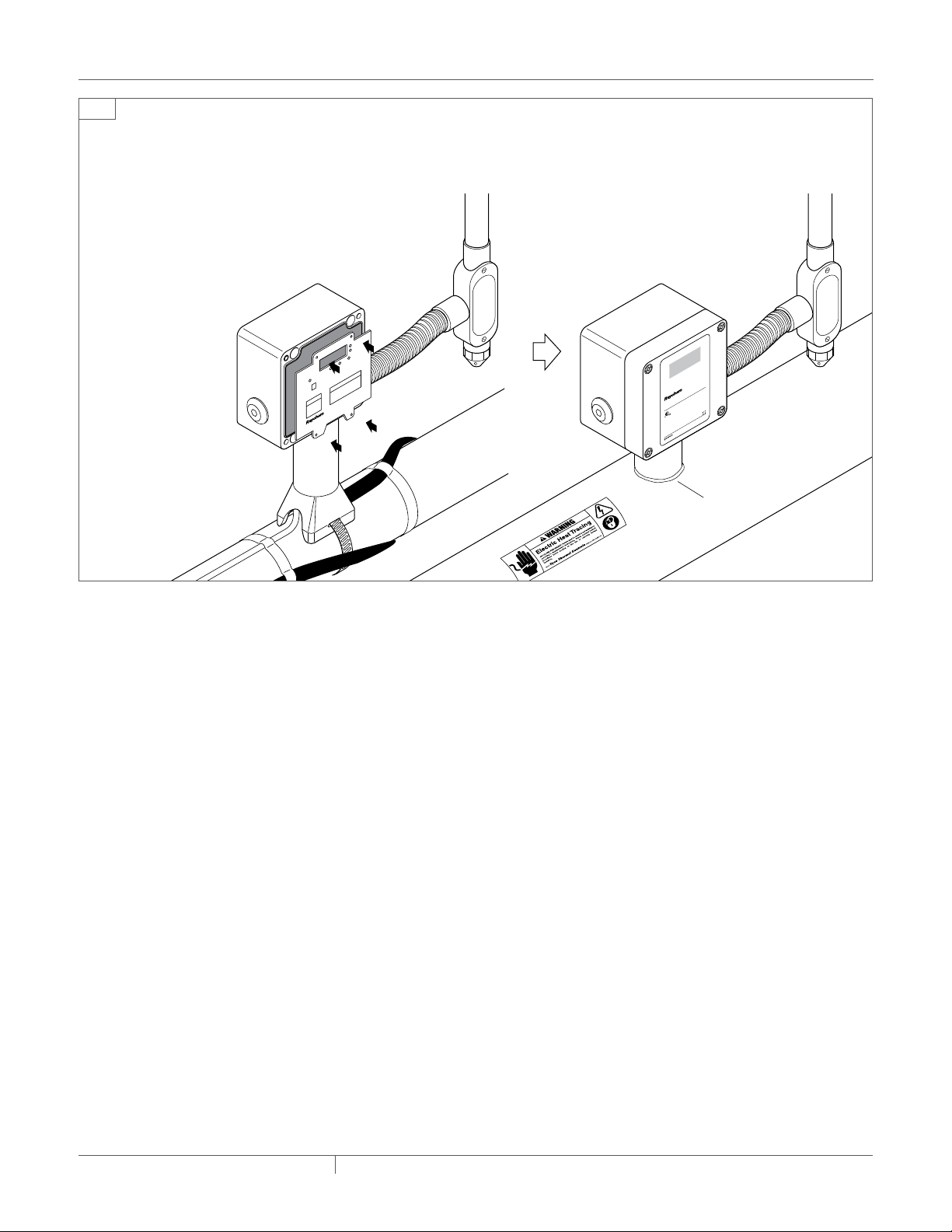

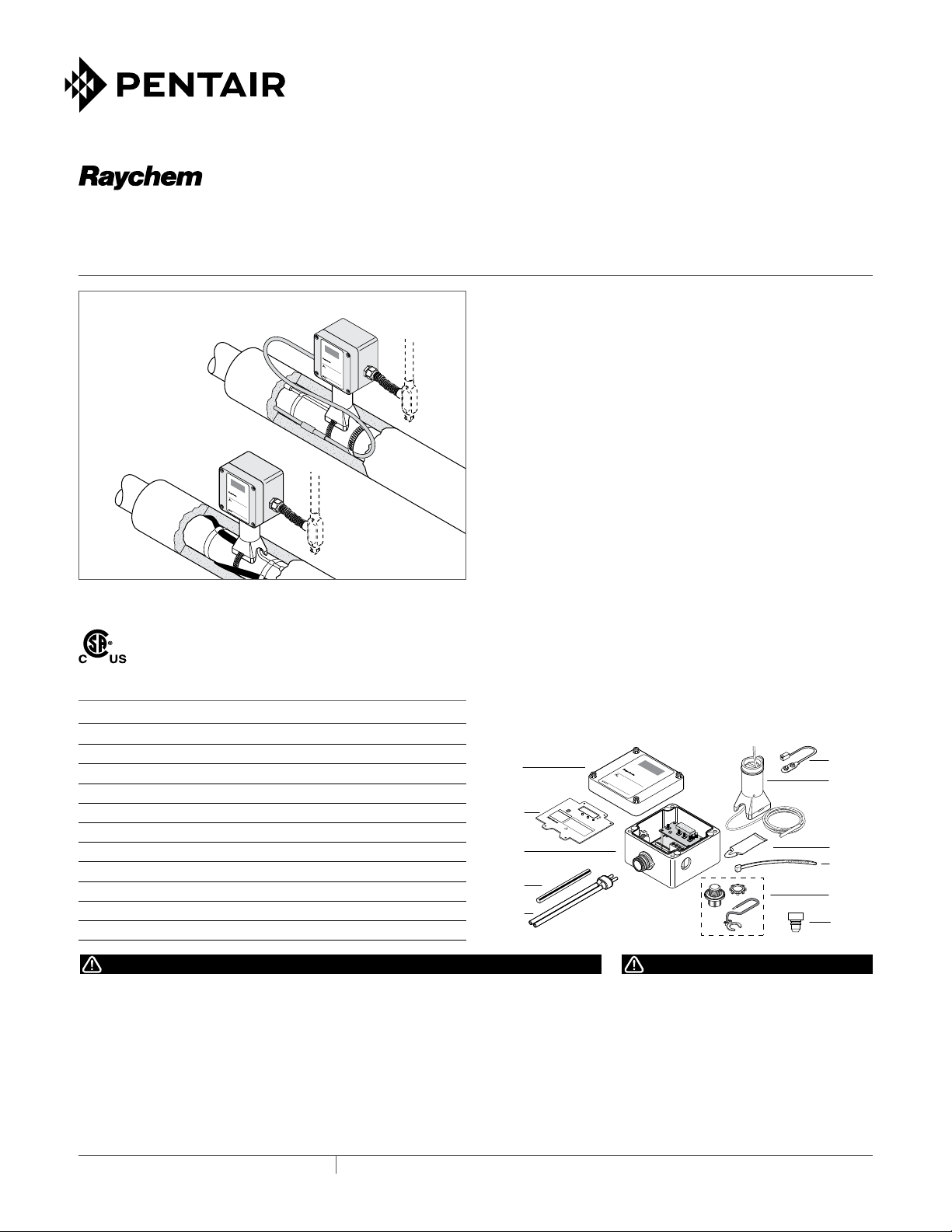

JBS-100-ECP-A with

Pyrotenax MI heating cable

using required MI cable

grounding kit

JBS-100-ECP-A with

Raychem heating cable

Actual

Setpoint

Temperature

JBS-100-ECP-A

Powerconnectionboxand digital electroniccontroller

Type4X

Input: 100-277Vac,50/60 Hz, 30 A

Output: 100-277Vac,30 A

MaximumAmbient: 140˚F(60˚C)

Formaintainingtemperatures up to 425 ˚F (220˚C)

innonhazardouslocations.

Usesupplywires suitable for at least 221˚F (105˚C).

Useonlywith certified Raychem BTV, QTVR, XL-Trace, XTV and VPL

heatingcablesand Raychem type A & D MI heating cables in

nonhazardouslocation.

©2004-2014PentairThermal Management LLC

WWW.PENTAIRTHERMAL.COM

PNP000000173 H57496 05/14

Actual

Setpoint

Temperature

JBS-100-ECP-A

Powerconnectionboxand digital electroniccontroller

Type4X

Input: 100-277Vac,50/60 Hz, 30 A

Output: 100-277Vac,30 A

MaximumAmbient: 140˚F(60˚C)

Formaintainingtemperatures up to 425˚F (220˚C)

innonhazardouslocations.

Usesupplywires suitable for at least 221˚F (105˚C).

Useonlywith certified Raychem BTV, QTVR, XL-Trace, XTV and VPL

heatingcablesand Raychem type A & D MI heating cables in

nonhazardouslocation.

©2004-2014PentairThermal Management LLC

WWW.PENTAIRTHERMAL.COM

PNP000000173 H57496 05/14

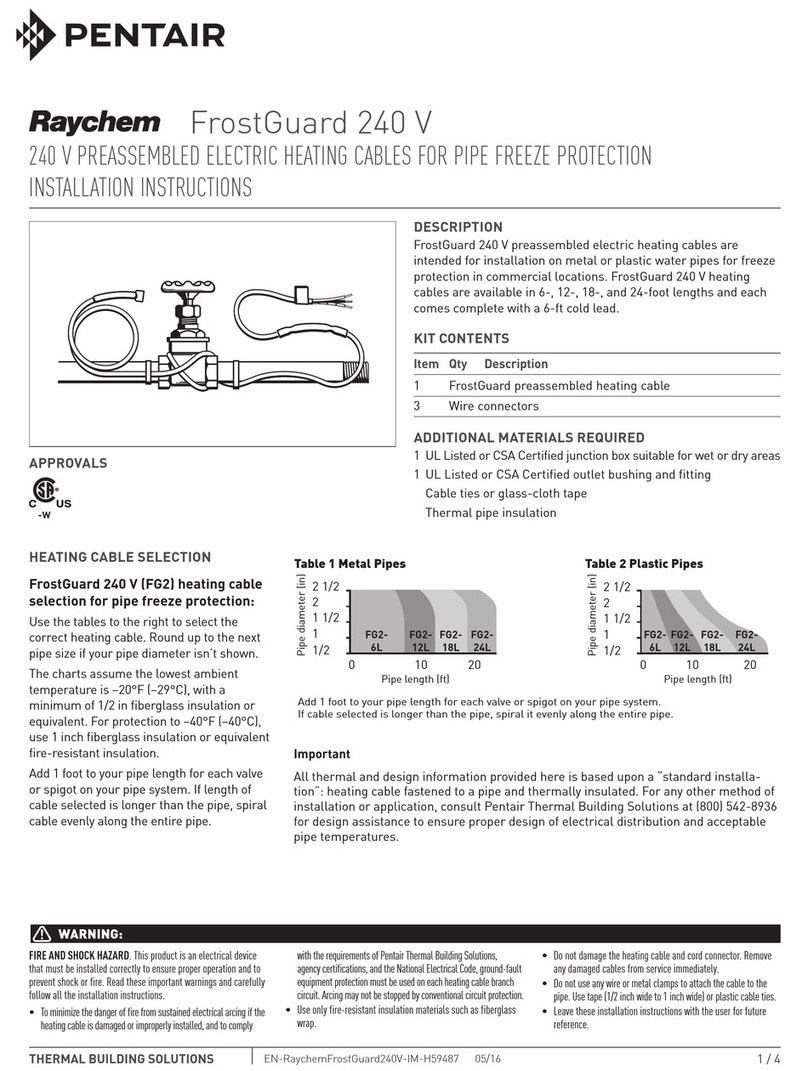

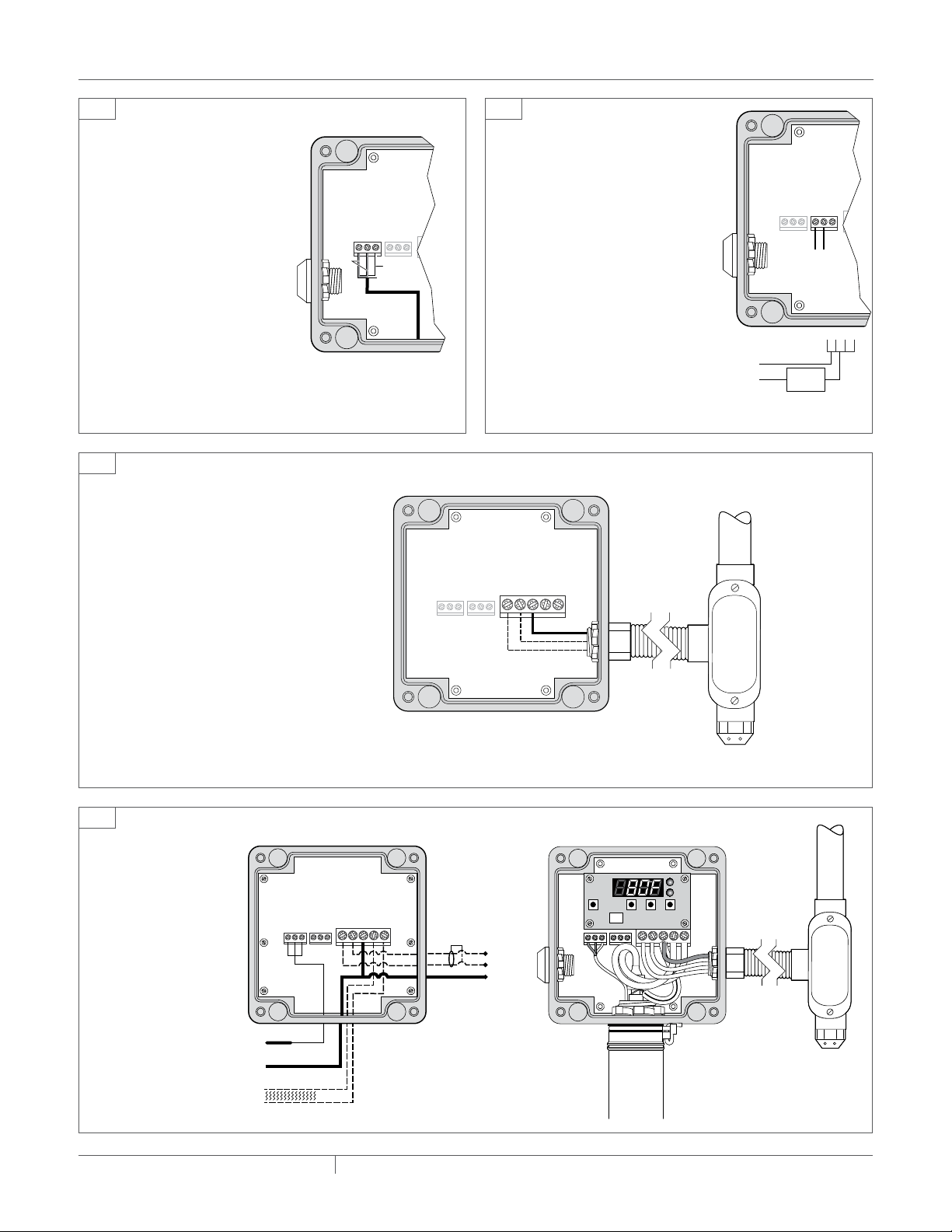

DESCRIPTION

The Raychem JBS-100-ECP-A is an electric heat-tracing power

connection / electronic controller combination housed in a NEMA 4X

rated enclosure. It is designed for use only with Raychem BTV-CR,

XL-Trace, BTV-CT, QTVR-CT, XTV-CT, VPL-CT, KTV-CT, and Pyrotenax

MI heating cables in nonhazardous locations.

These kits may be installed at temperatures as low as −40°F (−40°C).

For easier installation store above freezing until just before installation.

The controller can be programmed to maintain temperatures of 425°F

(220°C). It operates at voltages from 100 to 277 Vac and can switch

current up to 30 Amps.

For technical support call Pentair Industrial Heat Tracing Solutions at

(800)545-6258.

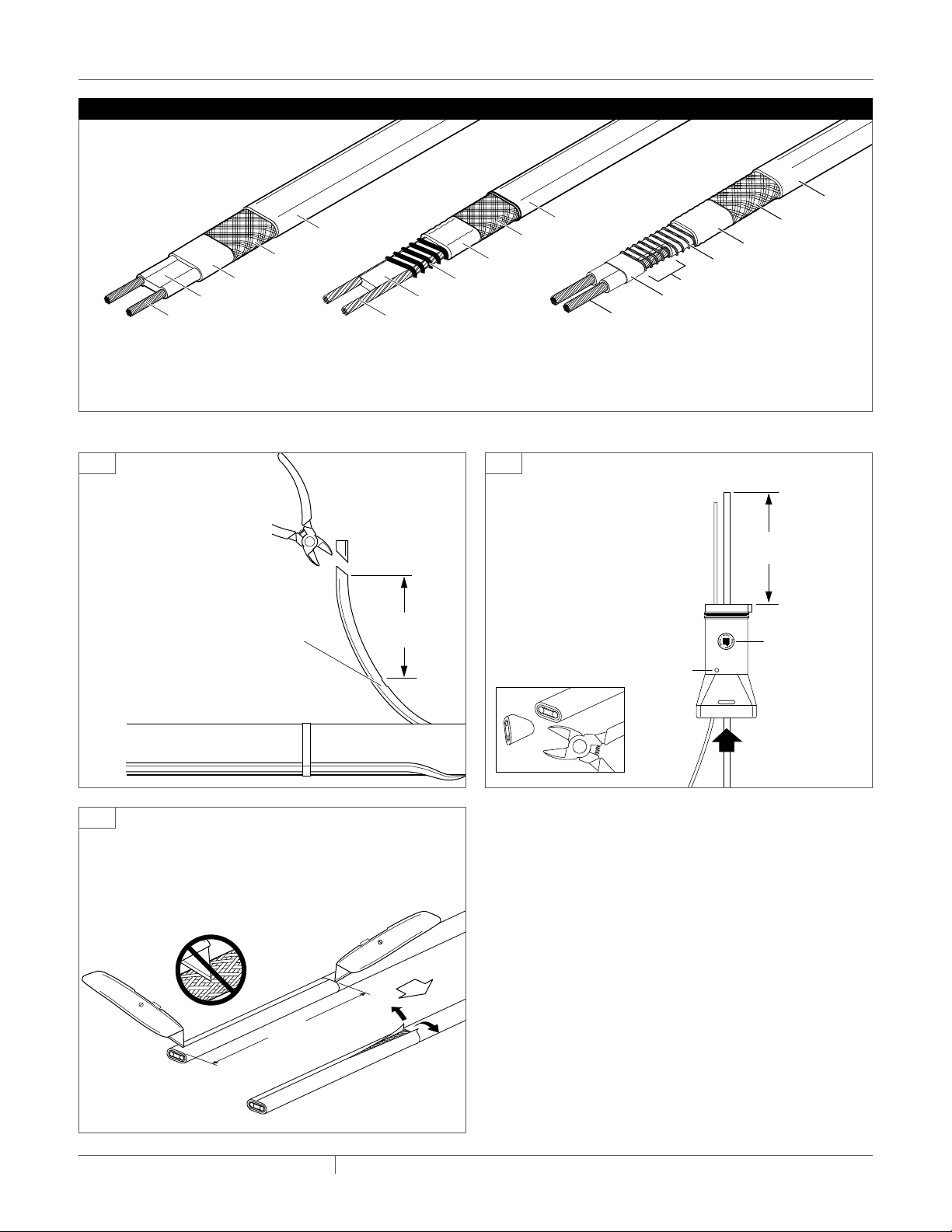

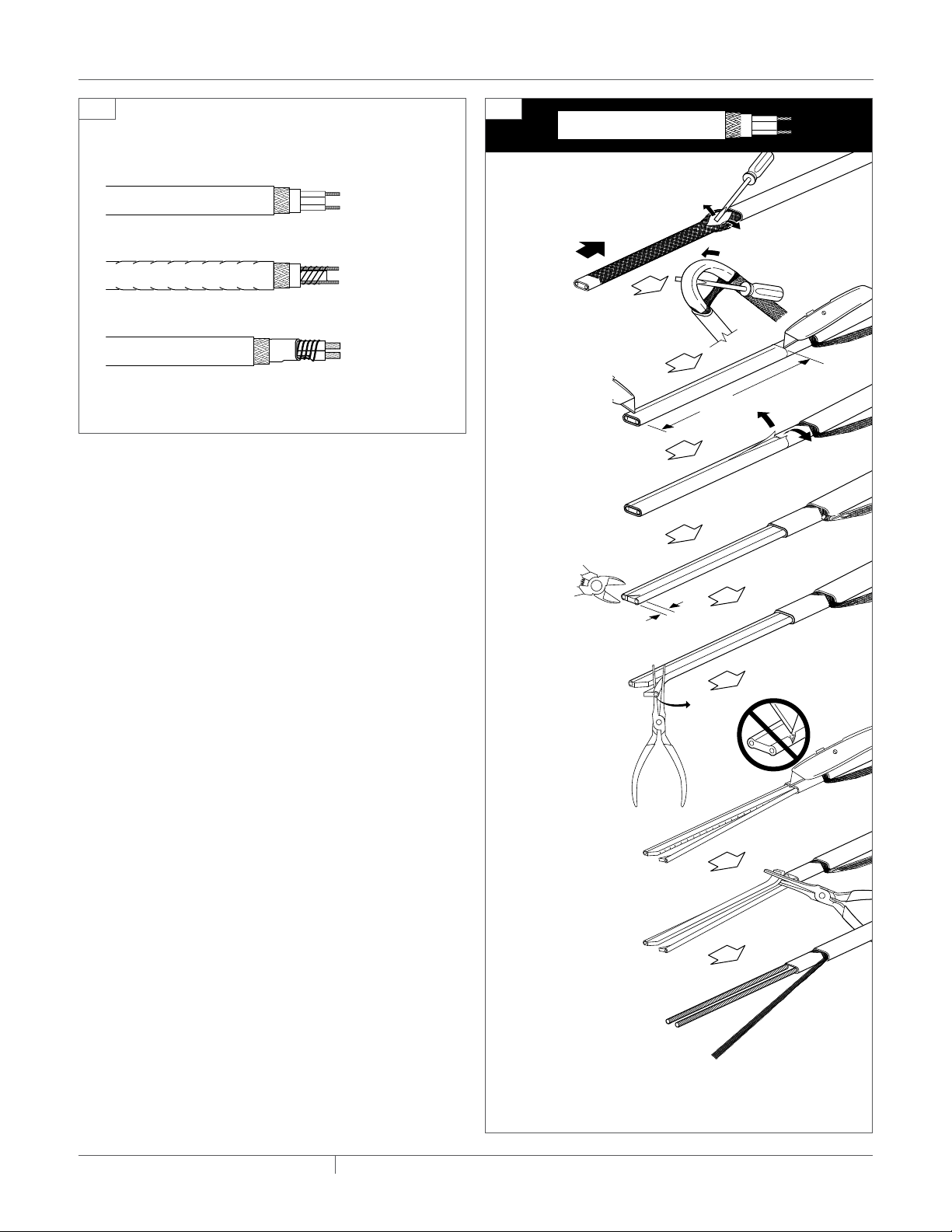

TOOLS REQUIRED

• Wirecutters • Pliersoradjustablewrench

• Utilityknife • Largeslottedscrewdriver

• Needlenosepliers • Smallslottedscrewdriver

• Wirestripper(forVPL-CT)

ADDITIONAL MATERIALS REQUIRED

• Pipestrap

• GT-66orGS-54fiberglasstape

• MIcablegroundingkit(forMIcableinstallations)

CatalogNo:MI-GROUND-KIT

• AT-180aluminumtape

• Smallpipeadapter(for1in(25mm)andsmallerpipes)

Catalog No: JBS-SPA

This component is an electrical device that must be installed

correctly to ensure proper operation and to prevent shock or fire.

Read these important warnings and carefully follow all of the

installation instructions.

• Tominimizethedangeroffirefromsustainedelectricalarcing

if the heating cable is damaged or improperly installed, and to

comply with the requirements of Pentair Industrial Heat Tracing

Solutions, agency certifications, and the National Electrical

Code, ground-fault equipment protection must be used. Arcing

may not be stopped by conventional circuit breakers.

• Componentapprovalsandperformancearebasedontheuseof

Pentair Industrial Heat Tracing Solutions-specified parts only.

Do not use substitute parts or vinyl electrical tape.

• Theblackheatingcablecoreandfibersareconductiveandcan

short. They must be properly insulated and kept dry.

• Damagedbuswirescanoverheatorshort.Donotbreakbuswire

strands when scoring the jacket or core.

• Keepcomponentsandheatingcableendsdrybeforeandduring

installation.

• Useonlyfireresistantinsulationmaterials,suchasfiberglass

wrap or flame-retardant foam.

HealtH Hazard: Prolonged or repeated contact with the

sealant in the core sealer may cause skin irritation. Wash hands

thoroughly. Overheating or burning the sealant will produce

fumes that may cause polymer fume fever. Avoid contamination

of cigarettes or tobacco. Consult MSDS VEN 0058 for further

information.

CHEMTREC 24-hour emergency telephone:

(800) 424-9300

Non-emergency health and safety information:

(800) 545-6258.

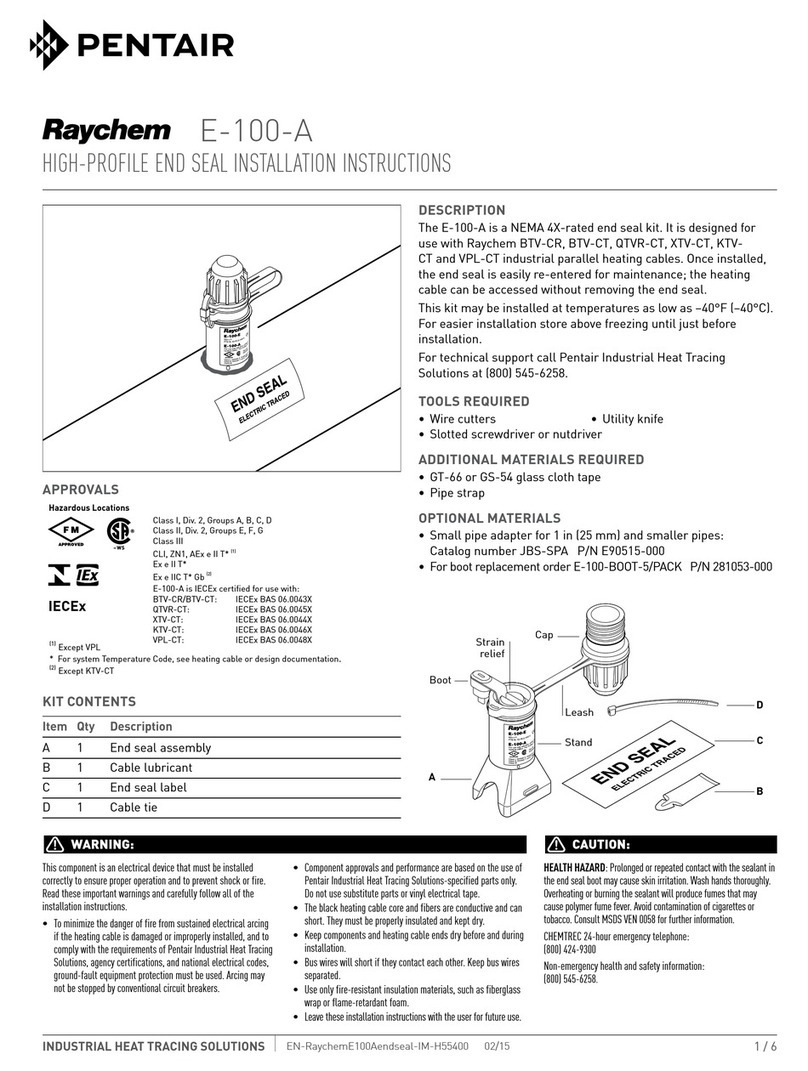

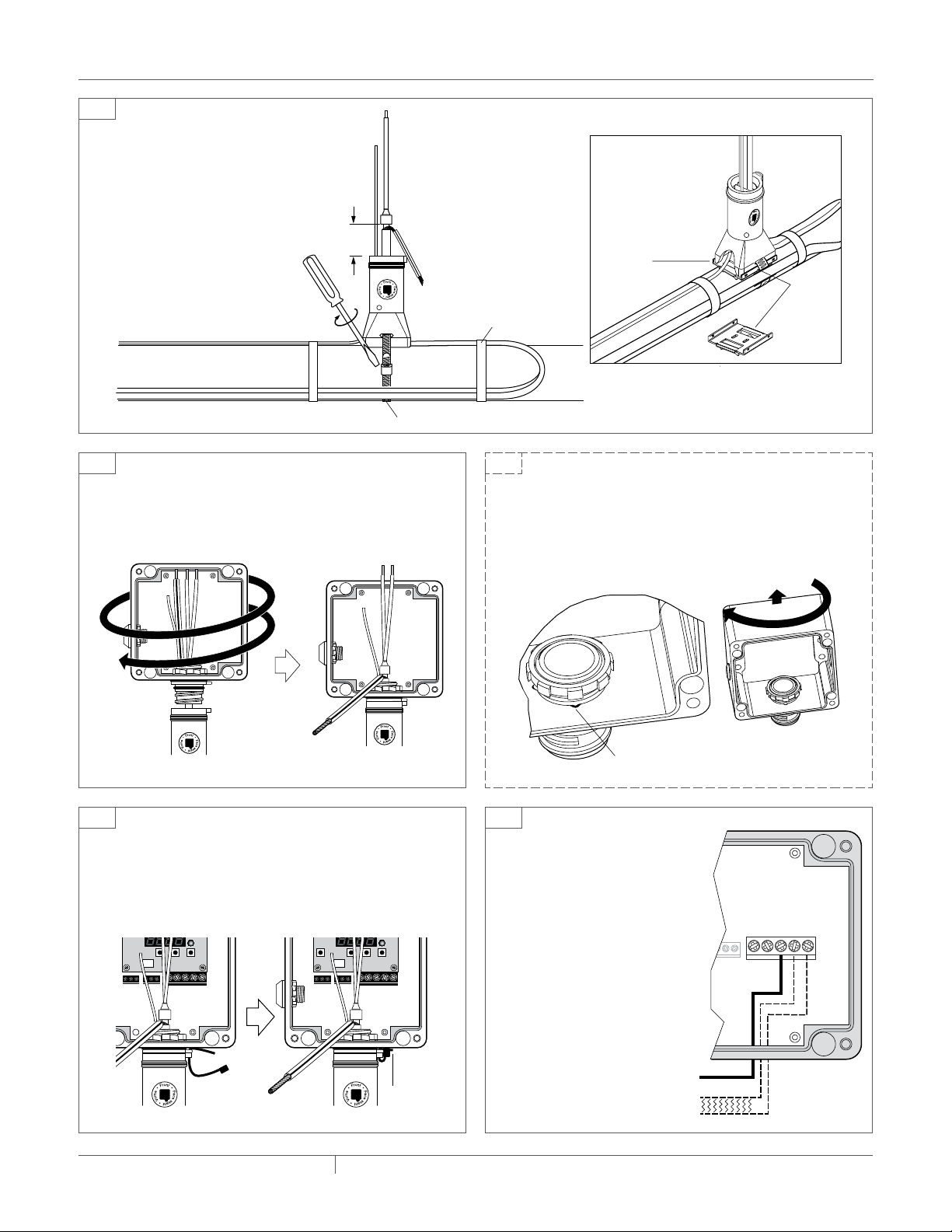

KIT CONTENTS

Item Qty Description

A 1 Lid

B 1 Wirecover

C 1 Box with electronics

D 1 Green/yellowtube

E 1 Core sealer (for use with Raychem heating cables only)

F 1 Battery connector

G 1 StandwithRTD

H 1 Cable lubricant (for use with Raychem heating cables only)

I 1 Cable tie

J 1 MI cable grounding kit (ordered separately; P000000279)

K 1 Plug (for use with MI cable installations only)

APPROVALS

Nonhazardous locations

A

G

F

H

I

B

C

D

EK

J

Actual

Setpoint

Temperature

JBS-100-ECP-A

Powerconnectionbox and digitalelectroniccontroller

Type4X

Input: 100-277Vac, 50/60 Hz, 30 A

Output: 100-277Vac, 30 A

MaximumAmbient: 140˚F (60˚C)

Formaintaining temperatures up to 425˚F (220˚C)

innonhazardous locations.

Usesupply wires suitable for at least 221˚F (105˚C).

Useonly with certified Raychem BTV, QTVR, XL-Trace,XTV and VPL

heatingcables and Raychem type A & D MI heating cables in

nonhazardouslocation.

©2004-2014Pentair Thermal Management LLC

WWW.PENTAIRTHERMAL.COM

PNP000000173 H57496 05/14

Hold 3 Seconds

WARNING

Shock Hazard

ALARMS / ERRORS:

rtd Err = Shorted or Open Sensor

Hi Alr = High Alarm

Lo Alr = Low Alarm

Do not remove cover while energized

Ne pas enlever le couvert tant que le

régulateur est sous tension

TEMPERATURE

Next

MENU

Battery

Connection

Up Down

ACTUAL

SETPOINT

SETTINGS:

1 - *F or *C

2 - Set Point

3 - Dead Band

4 - High Alarm

5 - Low Alarm

JBS-100-EC-A

Digital Thermostat