1 / 10

EMK-XP

ElEctroMElt PowEr connEction and End SEal Kit inStallation inStructionS

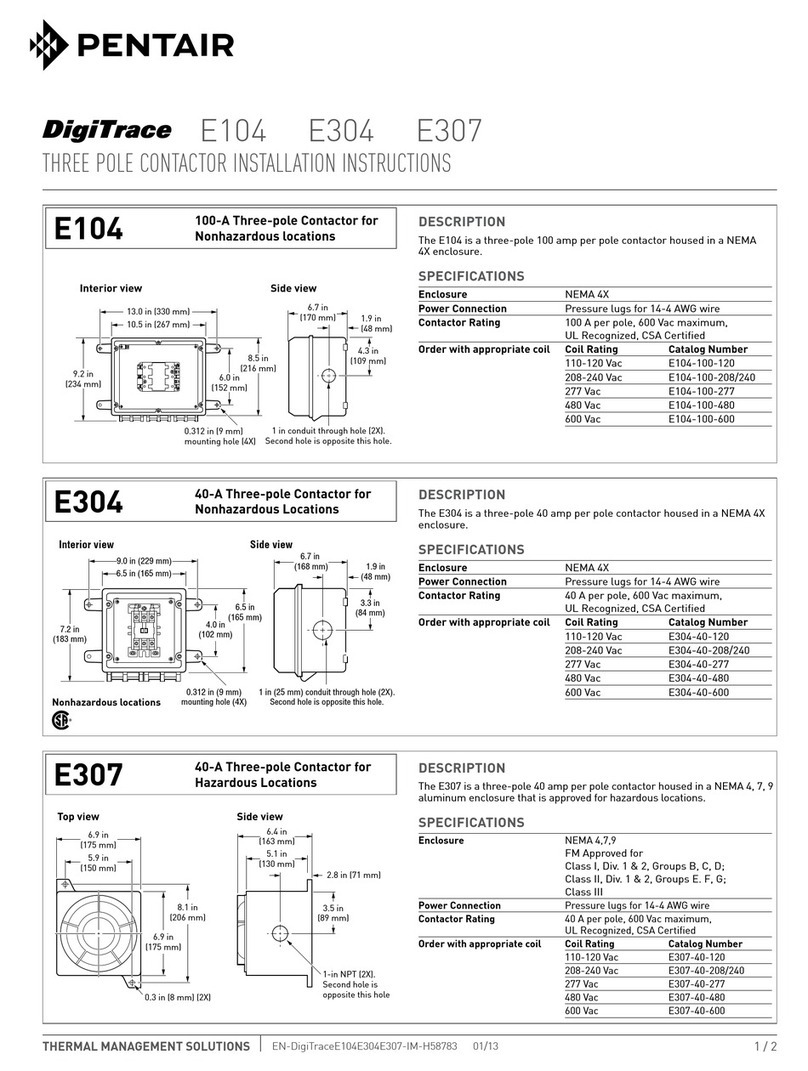

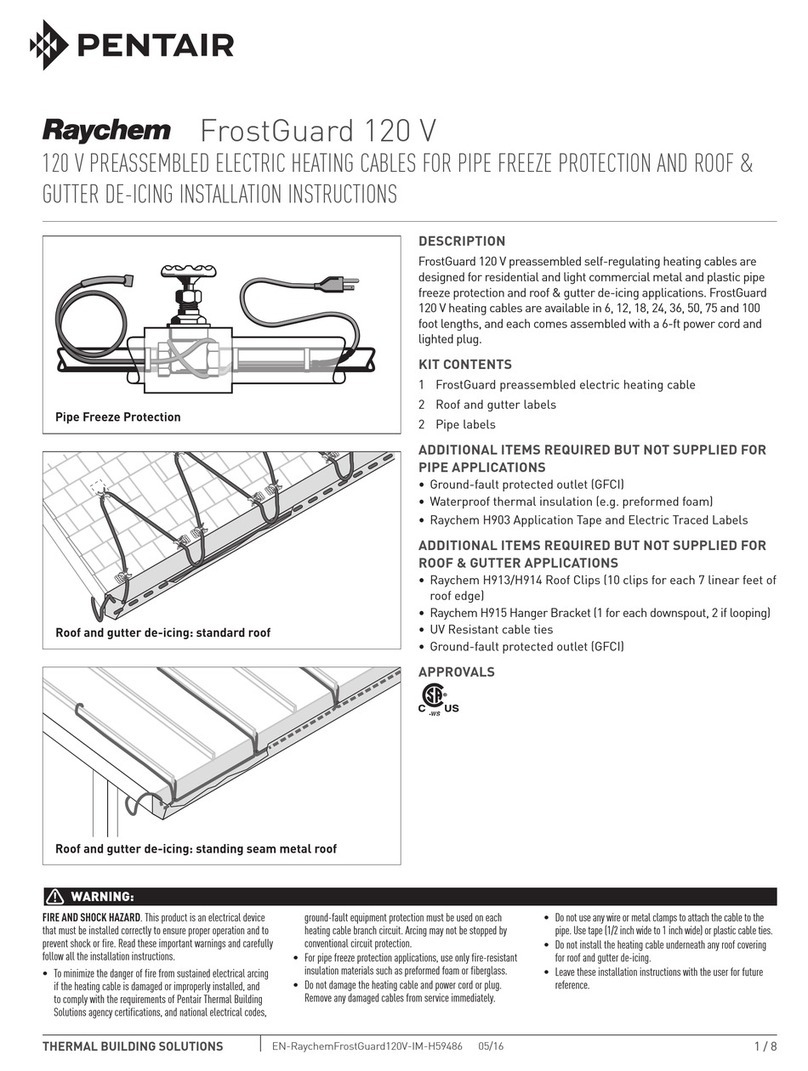

DESCRIPTION

The ElectroMelt EMK-XP Power Connection and End Seal Kit is for

use with ElectroMelt EM2-XR heating cable for snow-melting and

anti-icing applications. Materials for one power connection and

one end seal are included. This kit is suitable for connecting the

heating cable to 14 through 4 AWG (Cu only) power wires. Power

wiring must meet NEC or CEC requirements and have a minimum

temperature rating of 167°F (75°C).

These installation instructions should be used in conjunction with

the ElectroMelt System Design Guide (H53393) and ElectroMelt

System Installation and Operation Manual (H58086).

For technical support call Pentair Thermal Management at

(800)545-6258.

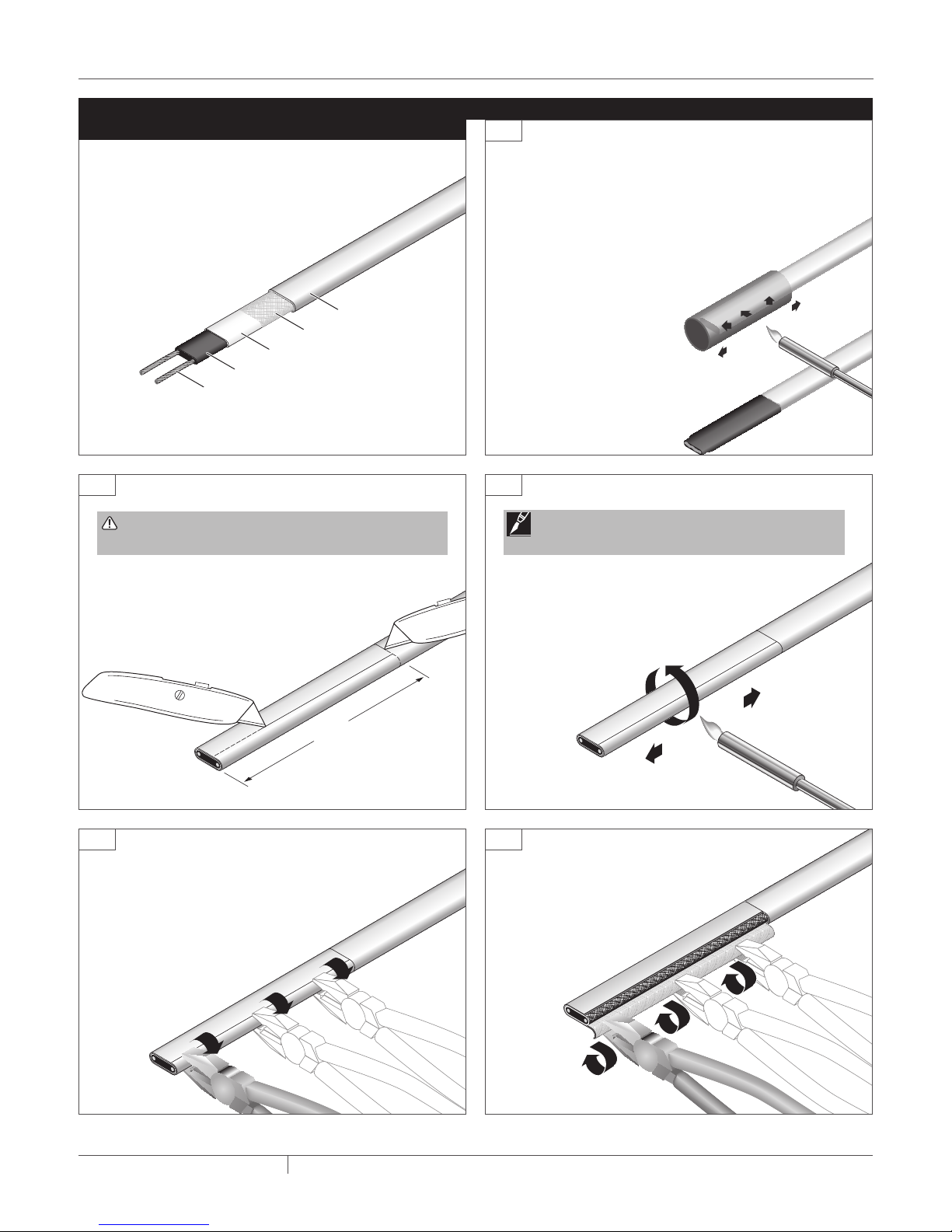

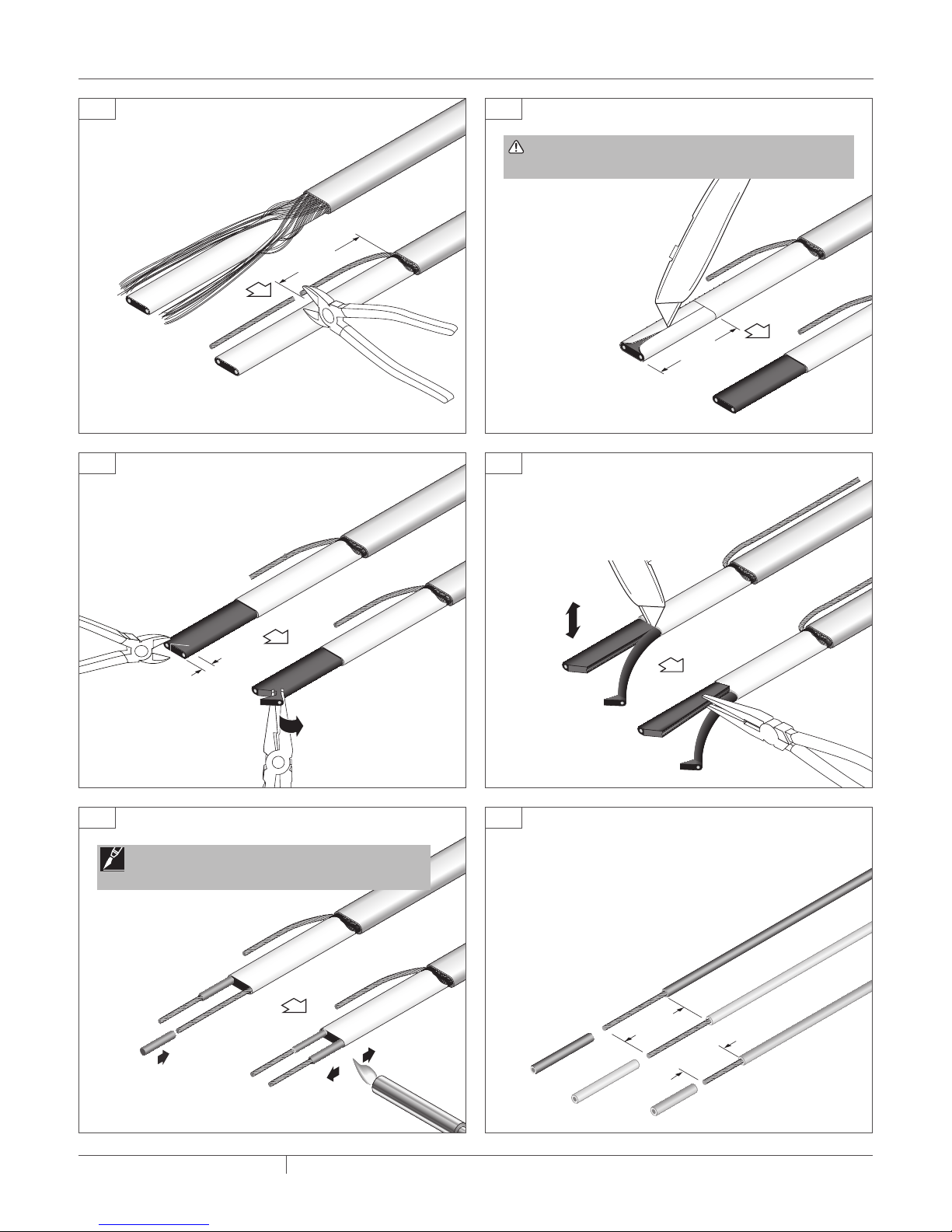

TOOLS REQUIRED

• Needle-nose pliers • Utility knife

• Heat gun or propane torch • Wire strippers

• Ideal Crimp Tool Model 30-425 • Diagonal cutters

ADDITIONAL MATERIALS REQUIRED

• EMK-XJB (Not shown) or equivalent UL Listed or CSA Certified

weatherproof junction box suitable for the location. A minimum

of 400 cubic inches are needed for 1 power connection and 1 end

termination per junction box.

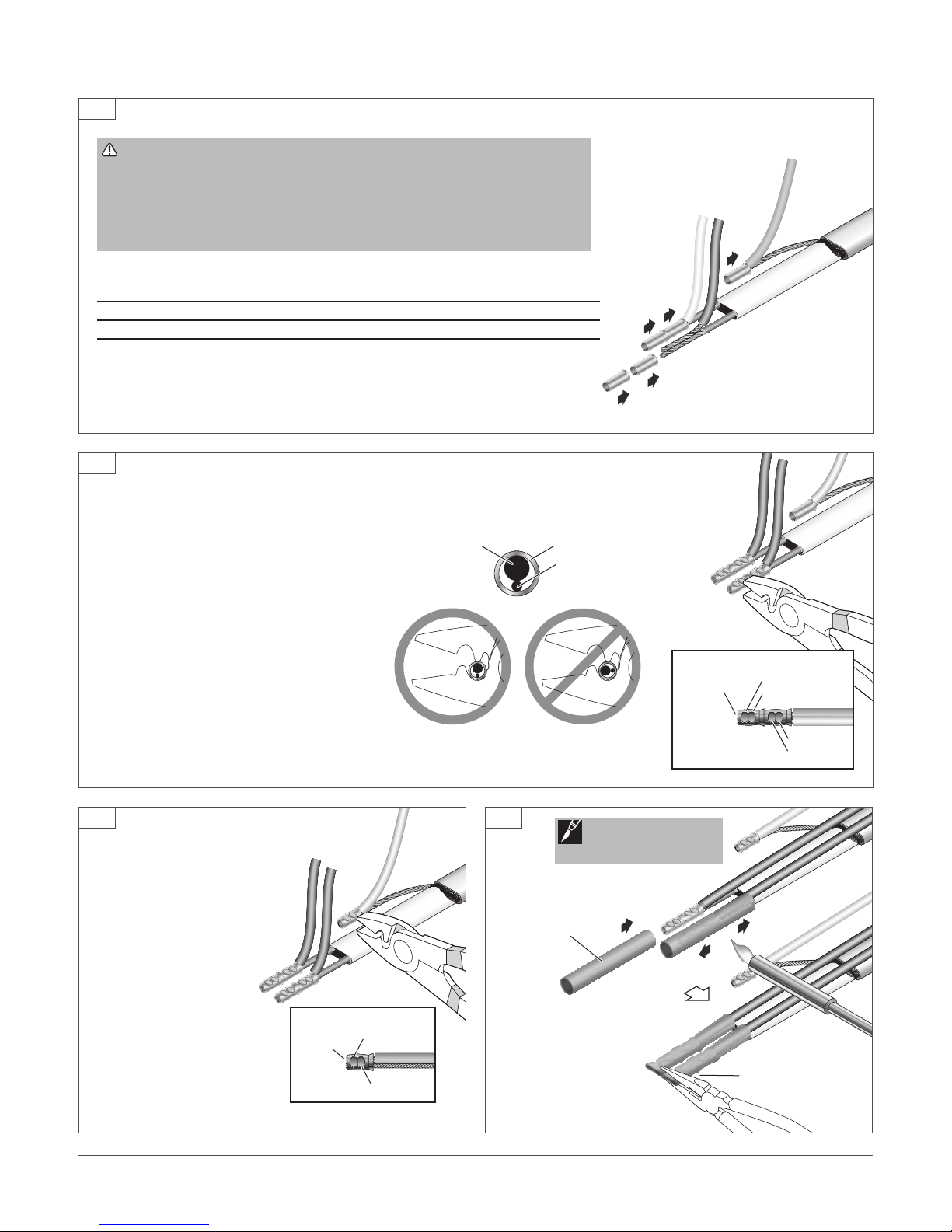

This component is an electrical device that must be installed correctly to ensure proper

operation and to prevent shock or fire. Read these important warnings and carefully follow

all the installation instructions.

• To minimize the danger of fire from sustained electrical arcing if the heating cable

is damaged or improperly installed, and to comply with the requirements of Pentair

Thermal Management, agency certifications, and national electrical codes, ground-

fault equipment protection must be used. Arcing may not be stopped by conventional

circuit breakers.

• Approvals and performance are based on the use of Pentair Thermal Management-

specified parts only. Do not substitute parts or use vinyl electrical tape.

• The black heating cable core is conductive and can short. It must be properly insulated

and kept dry.

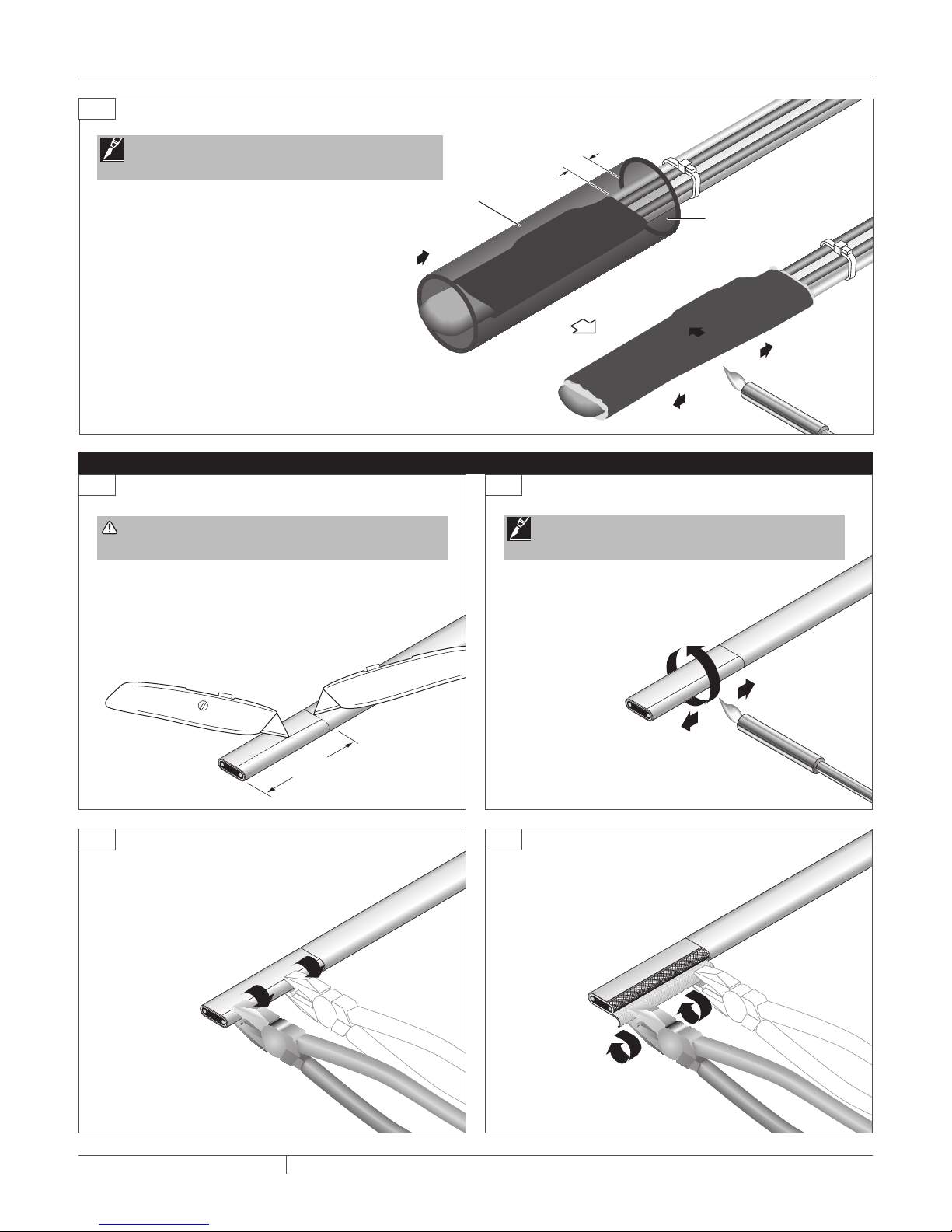

• Damaged bus wires can overheat or short. Do not break bus wire strands when scoring

the jacket or core.

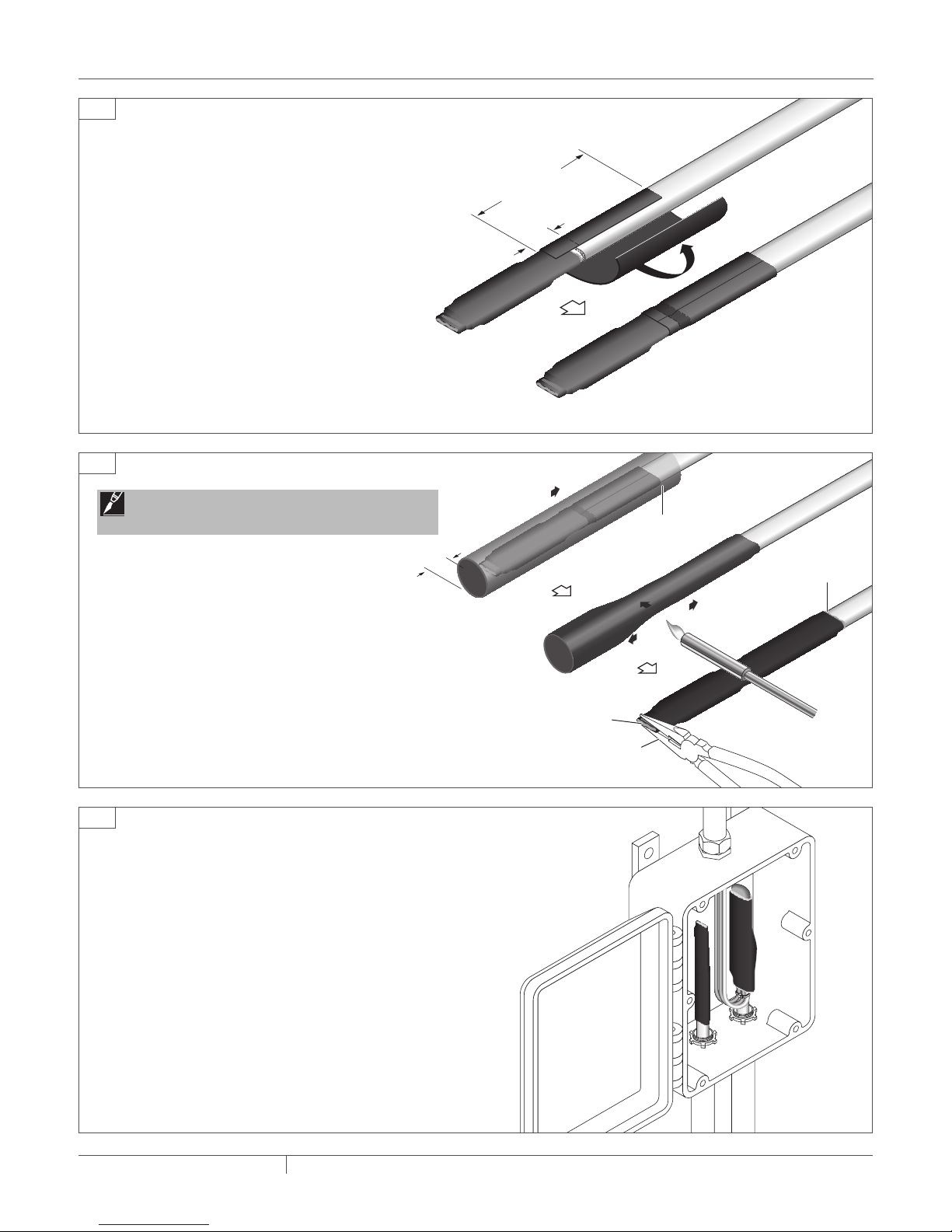

• Do not bury any of the components. Both the power connection and end seal must be

installed in a dry junction box.

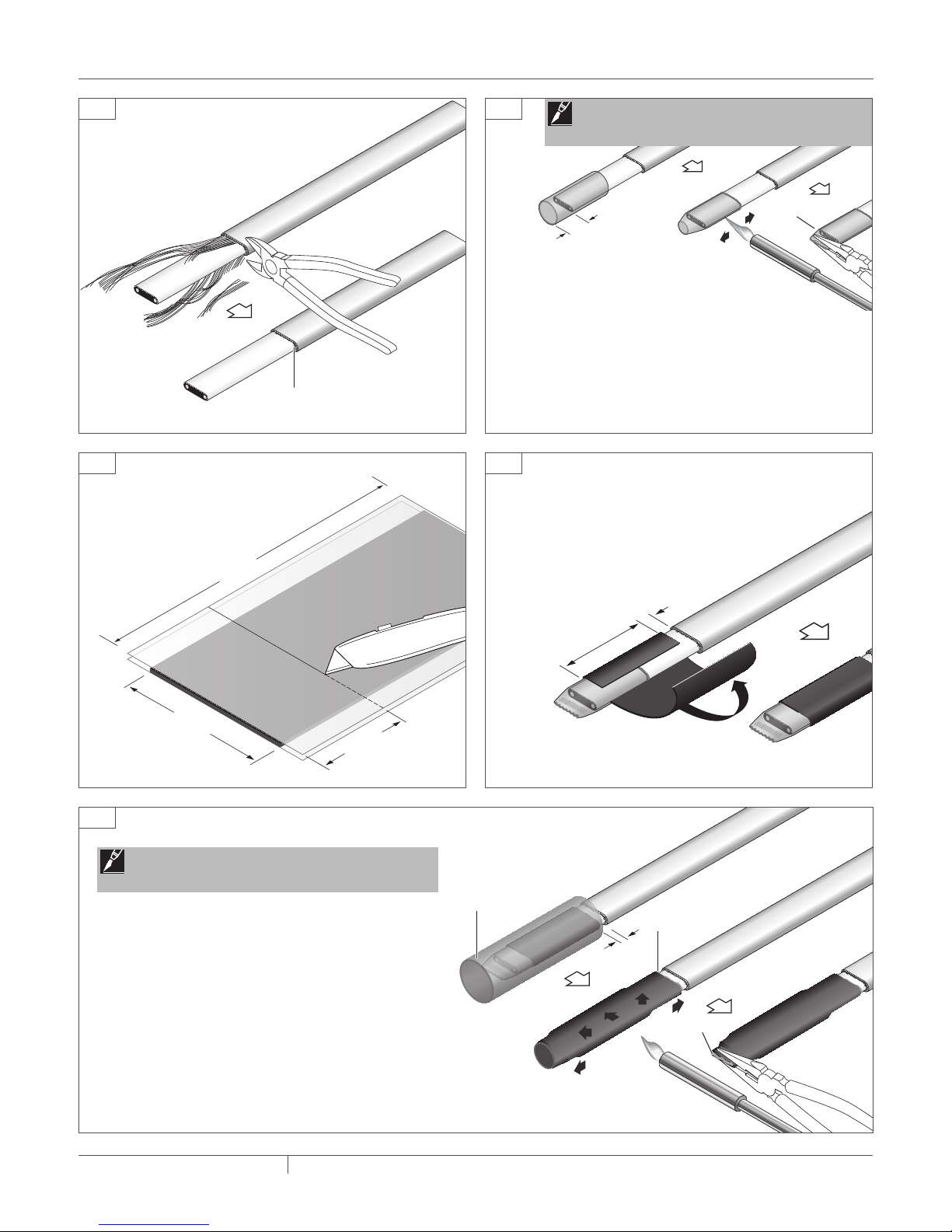

• Heat-damaged components can short. Use a heat gun or torch with a soft, yellow, low-

heat flame. Keep the flame moving to avoid overheating, blistering, or charring the

heat-shrinkable tubes. Avoid heating other components. Replace any damaged part.

• Bus wires will short if they contact each other. Keep bus wires separated.

• Connection kits and heating cable ends must be kept dry before and during

installation.

• Damaged heating cable can cause electrical arcing or fire. Use only plastic cable ties

to secure the heating cable to the reinforcement. Do not use metal attachments such

as tie wire.

• Do not attempt to repair or energize damaged heating cable. Remove damaged

sections at once and replace them with a new length using the appropriate Raychem

splice kit. Replace damaged connection kits.

• Megohmmeters operate at high voltage. This voltage is hazardous and possibly lethal.

Read and follow all instructions included with the instrument you are using.

HealtH Hazard: Over heating heat-shrinkable tubes will produce

fumes that may cause irritation. Use adequate ventilation and avoid

charring or burning. Consult MSDS RAY4566 for further information.

CHEMTREC 24-hour emergency telephone:

(800) 424-9300

Non-emergency health and safety information:

(800) 545-6258.

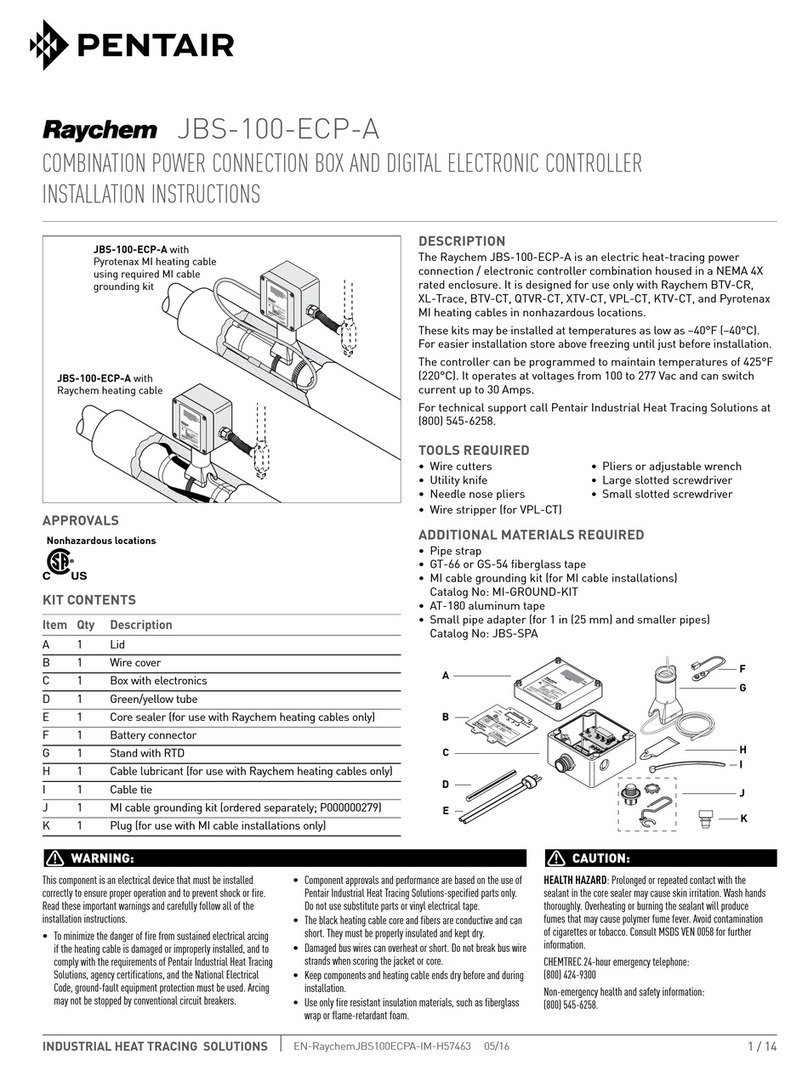

KIT CONTENTS

Item Qty Description

Power Connection

A 1 Black heat-shrinkable tube – 1 1/2 x 6 in (38 x 152 mm)

B 1 Heat-shrinkable cap

C 2 Clear yellow heat-shrinkable tubes – 1/2 x 2 3/4 in (13 x 70 mm)

D 1 Clear yellow heat-shrinkable tube – 1/2 x 2 in (13 x 51 mm)

E 2 “Electric Deicing and Snow Melting” labels

F 2 Black heat-shrinkable tubes – 1/8 x 3/4 in (3 x 19 mm)

G 5 Small non-insulated crimp connectors

H 5 Large non-insulated crimp connectors

I 1 Cable tie

J 1 Mastic sheet – 3 x 12 in (76 x 305 mm)

End Seal

A 1 Black heat-shrinkable tube – 1 1/2 in x 6 in (38 mm x 152 mm)

J 1 Mastic sheet – 3 in x 12 in (76 mm x 305 mm)

K 1 Black heat-shrinkable tube – 1 in x 3 in (25 mm x 76 mm)

L 1 Clear yellow heat-shrinkable tube – 1/2 in x 1 1/2 in (13 mm x 38 mm)

APPROVALS

LISTED

877Z

DE-ICING AND

SNOW MELTING EQUIPMENT

-W

A

B

C

D

E

F

G

H

I

J

K

L

THERMAL BUILDING SOLUTIONS Raychem-IM-H57284-EMKXP-EN-1612