Safety 2

Important Safety Instructions

Read the Owner’s Manual and related documentation

carefully before attempting to install or operate the

PENTEK INTELLIDRIVETM

. Make sure that you have a full

knowledge of the equipment, safety information, and

instructions before using this product.

Carefully read and follow all safety instructions in this

manual and on the VFD.

This is the safety-alert. When you see this symbol

on your VFD or in this manual, look for one of the

following signal words and be alert to the potential for

personal injury:

warns about hazards that will cause

serious personal injury, death or major property damage if

ignored.

warns about hazards that cancause

serious personal injury, death or major property damage if

ignored.

warns about hazards that will or can

cause minor personal injury or property damage if ignored.

The word NOTE indicates special instructions which are

important but not related to hazards.

To avoid serious or fatal personal injury and possible

property damage, carefully read and follow the safety

instructions.

Risk of high-voltage electrical shock

from the EMI/RFI Filter if the front cover of the VFD is

open or removed while power is connected to the VFD or

the VFD is running. The front cover of the VFD must be

closed during operation.

• After allowing at least 5 minutes for the EMI/RFI Filter

to discharge and before starting any wiring or

inspection procedures, check for residual voltage with

a voltage tester.

Risk of electrical shock if VFD is

connected to the power wiring before hanging the box.

Always hang the VFD box before connecting the wires to it.

Risk of electrical shock if the VFD is

handled or serviced with wet or damp hands. Always

make sure your hands are dry before working on the VFD.

Perform all operations on the HMI with dry hands.

Risk of electrical shock and hand

injury. Do not reach into or change the cooling fan while

power is on to the VFD.

Risk of electrical shock. Do not touch

the printed circuit board when power is on to the VFD.

Fire hazard if installed with incorrect or

inadequate circuit breaker protection. To make sure of

protection in the event of an internal fault in the VFD,

install the VFD on an independent branch circuit protected

by a circuit breaker (see Table 2, Page 6 for circuit breaker

sizing), with no other appliances on the circuit.

Risk of burns.The drive can become

hot during normal operation. Allow it to cool for 10

minutes after shut-down before handling it to avoid burns.

Risk of electric shock.A means for

disconnection from the supply mains, having a contact

separation in all poles, must be incorporated in the fixed

wiring in accordance with the wiring rules.

Complex equipment. This device is not

intended for use by persons (including children) having

reduced physical, sensory or mental capabilities, or lack of

experience and knowledge.

NOTE: This VFD is classified as Class A EMC/EMI

equipment. It is intended for use in an industrial

environment. There may be potential difficulties ensuring

electromagnetic compatibility in other environments due

to conducted as well as radiated disturbances.

NOTE: The device must be supplied through a Type A

Residual Current Device (RCD) having a rated residual

operating current not exceeding 30 mA.

NOTE: To avoid damage to the drive or problems with the drive:

• Connect the output cables to 3-wire submersible

motors as described in Output Connections, page 7.

Any other order will reverse the motor rotation and

may damage the motor.

• Do not modify the equipment.

• Do not use power factor correction capacitors with this

VFD; they will damage both the motor and the VFD.

• Do not remove any parts unless instructed to do so in

the owner’s manual.

• Do not use a magnetic contactor on the VFD for

frequent starting/stopping of the VFD.

• Do not install or operate the VFD if it is damaged or

parts are missing.

• Before starting a VFD that has been stored for a long

time, always inspect it and test operation.

• Do not carry out a megger (insulation resistance) test

on the control circuit of the VFD.

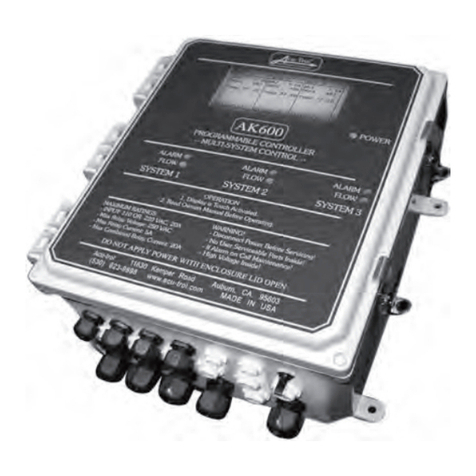

Risk of high-voltage electrical shock

from EMI/RFI Filter inside Drive.

Make all wiring connections, then

close and fasten the cover before

turning on power to Drive.

DO NOT open the box when power is

connected to the Drive.

Before doing any service

or maintenance inside

the Drive:

1. DISCONNECT power.

2. WAIT 5 minutes for

retained voltage to

discharge.

3. Open box.

Before connecting or

disconnecting any wires

inside the Drive:

1. DISCONNECT power.

2. WAIT 5 minutes for

retained voltage to

discharge.

3. Open box.

PID_OM_2014.indd 2 24/02/2014 1:49:52 PM