PENTAIR® EVERPURE® ENDURANCE HIGH-FLOW WATER FILTRATION SYSTEMS INSTALLATION, OPERATION & MAINTENANCE GUIDE • 3

5. Secure the pretreatment bracket with the head to the desired

location. Use the screw holes from the previous step for mounting.

6. Use a section of 3/4" I.D. tubing to reconnect the pretreatment

outlet to the inlet of the manifold. The pretreatment outlet cannot

be more than 25 feet from the manifold. The tubing should have

clamps at each end with no sharp bends or kinks.

NOTE:Use tubing that is opaque and suitable for use with

beverages.

7. Mount the manifold using four (4) screws in the bracket mounting

holes.

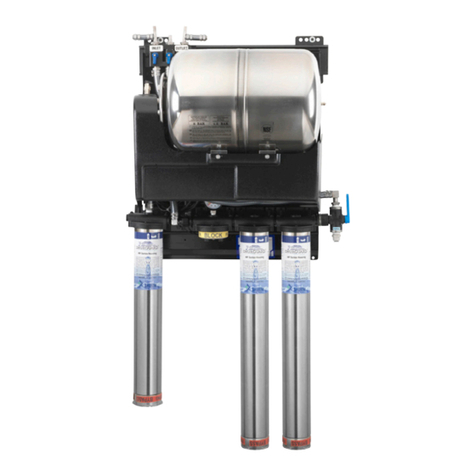

8. Connect the treated water outlet port to the equipment being

served (Figure 2).

Figure 2

Flush Valve

3/8" Barb

Treated Water Outlet

3/4" NPT

Scale Inhibitor Outlet 1/2" Barb

Untreated Water Inlet

3/4" NPT

9. Connect the untreated water to the inlet tting on the

pretreatment head (Figure 2).

10. Attach 3/8" I.D. tubing to the ush valve tting (Figure 2). Run the

other end of the tubing to a drain.

NOTE: Some plumbing codes require an air gap at the drain

termination.

11. The 2SR-BW does not have a shut off valve. Attach 1/2" I.D.

tubing to the outlet barb of the 2SR-BW head. Route the other

end of the tubing to the equipment being served. Both ends of

the tubing should be clamped to the hose barb.

12. Turn off the ow valves for the inlet, ush and scale inhibitor

cartridge (2SR-BW) (Figure 2).

13. Check to be sure the O-ring on the pretreatment housing is

suciently lubricated. Use a good grade of silicone lubricant,

if needed. Unwrap the pretreatment cartridge. Position the

pretreatment cartridge on guide seat in the bottom of the bowl.

Then thread the bowl into the head by hand. Use a sump wrench

to lightly tighten the bowl onto the head. This bowl can be

tightened further if leaks occur later. The two O-rings at the top

of the cartridge will t snuggly into the head.

NOTE:To install the carbon lter and scale inhibitor cartridges,

align the cartridge lug with the label, push upward and

rotate to the right (cw) until rotation stops.

14. Install only genuine Pentair Everpure carbon lter cartridge(s)

into the lter head(s) following directions on the SEN

cartridge label or as shown in the Cartridge Change Procedure

illustrations. Install the scale inhibitor cartridge (2SR-BW).

CAUTION: Unused manifold ports must be plugged. Any ports

that are not plugged will leak.

15. Open the ush valve then turn on the inlet water. Open the valve

on the pretreatment head. Water will ush to the drain at full

force. Allow the system to ush for ve (5) minutes. This will set

the ltering media and purge any air.

16. After ushing, close the ushing valve. The pressure gauge will

show the system pressure when the cartridges are new.

17. Open the valve for the scale inhibitor cartridge. The Endurance

High Flow system is now ready for use.

FLUSHING

For maximum life, all carbon lter cartridges must be ushed for

ve minutes at full ow before use. FLUSH ALL CARTRIDGES AFTER

EACH CARTRIDGE CHANGE.

If the new cartridges have been adequately ushed and the

pressure gauge needle registers inadequate pressure; you may be

experiencing insucient water pressure or some restriction may

exist in the inlet water line. In either case, the water pressure needs

to be improved to achieve optimum lter life.

If the system is switched off for more than 48 hours, ush for at

least two (2) minutes.

CARTRIDGE CHANGE DETERMINATION

Replace all lter cartridges annually, when capacity is reached or

when water pressure or ow to equipment becomes inadequate. All

cartridges on multiple cartridge systems should be changed at the

same time.

The system pressure gauge provides a quick, simple means of

determining when the lter cartridge(s) should be checked. It is

installed on the system outlet manifold. The gauge can be used

to monitor both dynamic (owing) and static (line) pressure. The

cartridge(s) should be changed when the pressure gauge is in the

red area while the equipment is in operation, and the needle shows

adequate line pressure between cycles. Observe the needle during

the next equipment on cycle. If the needle registers adequate

pressure, it can be assumed that the temporary low-pressure

condition was caused by a brief power failure or other incoming

pressure disruption. If the low pressure condition is not due to an

external condition, check/change the pretreatment lter rst. If the

low pressure condition is still not corrected, change the SEN carbon

lter cartridges.