3

VERUS®850 Premium Efficient Aquaculture Duty Pump Installation and User’s Guide

VERUS®850 Premium Efficient Aquaculture Duty Pump Installation and User’s Guide

Mechanical Installation (Continued)

7. Placethepumpinitsnallocationandensure

that the mating anges of the suction and

dischargepipingareinlineandparalleltothe

angesonthepump.Resolveanyproblems

withmisalignmentbeforeboltingtheanges

tothepump.

8. Thepumpmaybesecuredtoboltsburiedin

theconcretebyusingtheholesontheoutside

ofthemotorsupports.

9. Ensure that the ange gasket is properly

positionedbetweenthesuctionangeofthe

pumpandtheangeofthesuctionpiping.

Useonlyhighqualityrubber,fulldiameter

angegasketswithholesfortheboltstopass

through.Itmaybenecessarytoholdthegasket

inplacewitheithersiliconeortwoorthree

dropsofacyanoacrylate(superglue)material.

Donotuseanyothergreaseorglueasthey

maycontainchemicalsthatcouldattackthe

plasticmaterial.Installtheangeboltshand

tightonthesuctionsideofthepump.

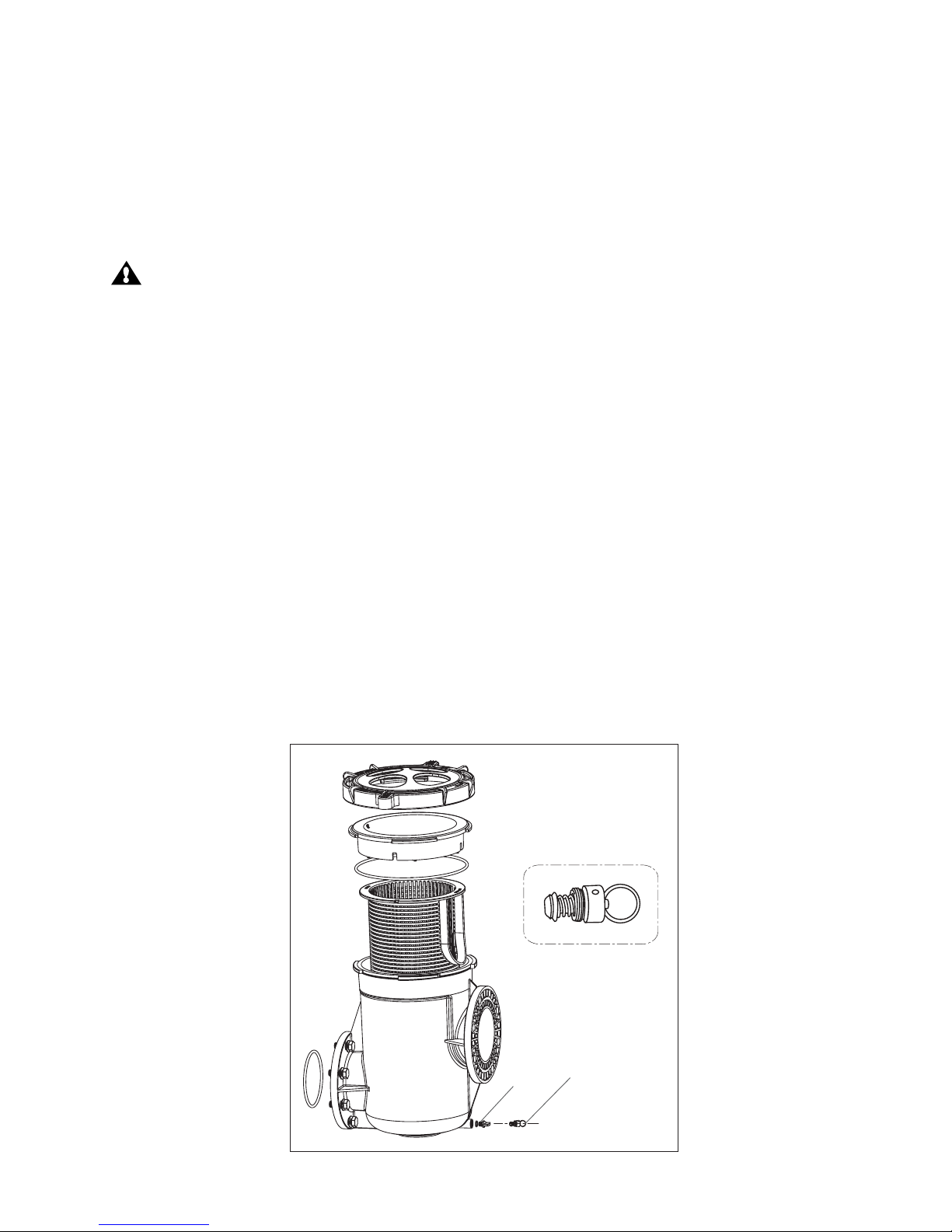

* INCLUDED WITH STRAINER POT

HEX NUT M20 x 25 (5/8-11)

P/N 356788 *

P/N 356789 *

P/N 356766 *

(5/8" ID X 1-5/16") MIN OD

FLAT WASHER

(6" ANSI CLASS 150) FLANGE

SUCTION CONNECTIONWITH

STRAINER POT

70 DURO NITRILE OR EPDM

3.2 mm (1/8") THICK GASKET

22.1 mm (5/8" ID X 1-5/16") MIN OD

FLAT WASHER

HEX HEAD CAP SCREW

M20 x 25, 80 mm (5/8-11 X 3-1/4") LG

Optional accessory flange kit

70 DURO NITRILE OR EPDM

3.2 mm (1/8") THICK GASKET

6" ANSI CLASS 150 FLANGE

SUCTION CONNECTIONWITHOUT

STRAINER POT

22.1 mm (5/8") ID X 44 mm (1-5/16") MIN OD

FLAT WASHER

HEX HEAD CAP SCREW

5/8-11 X 2-1/4" LG

Figure 1.

CAUTION — Some off the shelf, non-Pentair, 6” flange adapters will not work with pump without the strainer pot. Note

the tabs on the flange on the left, (Figure 3). These tabs will interfere with the strainer pot alignment

lip on the housing. This lip is used to locate the strainer pot on models that are so equipped. Please

contact Pentair for a replacement flange adapter kit (Pentair P/N 357212).

CAUTION — Use large diameter flat washers between the hex nut and the pump flanges to properly distribute the

clamping forces on the flange. Tighten the flanges to 20 ft.-lb. (27.1 newton/meters) unless otherwise

specified by the flange manufacturer. If it is not possible to use a torque wrench then care should be

taken not to over tighten the flange bolts. Failure to follow the above instructions can result in damage

to the pump flange.

10. Properlyinserttheangegasketonthedischargeportofthepump.Installtheangeboltshandtightonthe

dischargeangeconnection.

11. Inspectboththesuctionandangeconnectiontoensurealignmentremainsacceptable.Takeanycorrective

actionbeforetighteningtheangeboltstotherequiredtorque.

CAUTION — Suction and discharge piping must be supported by an appropriate system of supports or hangers.

Inadequately supported pipe can cause excessive loads to be transmitted to the pump resulting in a

structural failure of the pump that could result in flooding and property damage.

Flange kit part numbers (available separately)

• P/N 357259: FLANGE 2.5 INCH SCHEDULE-80 WITH GASKET AND S/S HARDWARE (QTY. 1)

• P/N 357260: FLANGE 5 INCH SCHEDULE-80 WITH GASKET AND S/S HARDWARE (QTY. 1)

• P/N 357261: FLANGE 3 INCH SCHEDULE-80 WITH GASKET AND S/S HARDWARE (QTY. 1)

• P/N 357262: FLANGE 4 INCH SCHEDULE-80 WITH GASKET AND S/S HARDWARE (QTY. 1)

• P/N 357263: FLANGE 6 INCH SCHEDULE-80 WITH GASKET AND S/S HARDWARE (QTY. 1)

• P/N 357212: FLANGE 6 INCH SCHEDULE-80 WITH GASKET AND S/S HARDWARE WITHOUT POT (QTY. 1)

OPTIONAL STRAINER POT ASSEMBLY (P/N 347013)

SUCTION CONNECTION WITH

STRAINER POT ASSEMBLY AND

OPTIONAL FLANGE KIT

SUCTION CONNECTION WITHOUT

OPTIONAL STRAINER POT ASSEMBLY

Figure 2.

Figure 3.

TABS