2

General Information

Attention:

This manual contains important

information for the safe use of this

product. Read completely and do not

throw away.

Reasonable care and safe methods

should be practiced. Check local codes

and requirements before installation.

Unpacking Pump:

When unpacking unit, check for damage.

Claims for damage must be made at

the receiving end through the delivery

carrier. Damage cannot be processed

from the factory.

WARNING: Before handling these

pumps and controls, always

disconnect the power first. Do not

smoke or use sparkable electrical

devices or flames in a septic

(gaseous) or possible septic sump.

CALIFORNIA PROPOSITION 65 WARNING:

This product and

related accessories contain

chemicals known to the State of

California to cause cancer, birth

defects or other reproductiveharm.

Pumps in Storage or Not Operating:

Pumps with silicon/carbide seals

must have impellers manually rotated

(6 revolutions) after setting non-

operational for 3 months or longer and

prior to electrical start-up.

Pumps with tungsten carbide seals

must have impellers manually rotated

(6 revolutions) after setting non-

operational for 3 weeks or longer and

prior to electrical start-up.

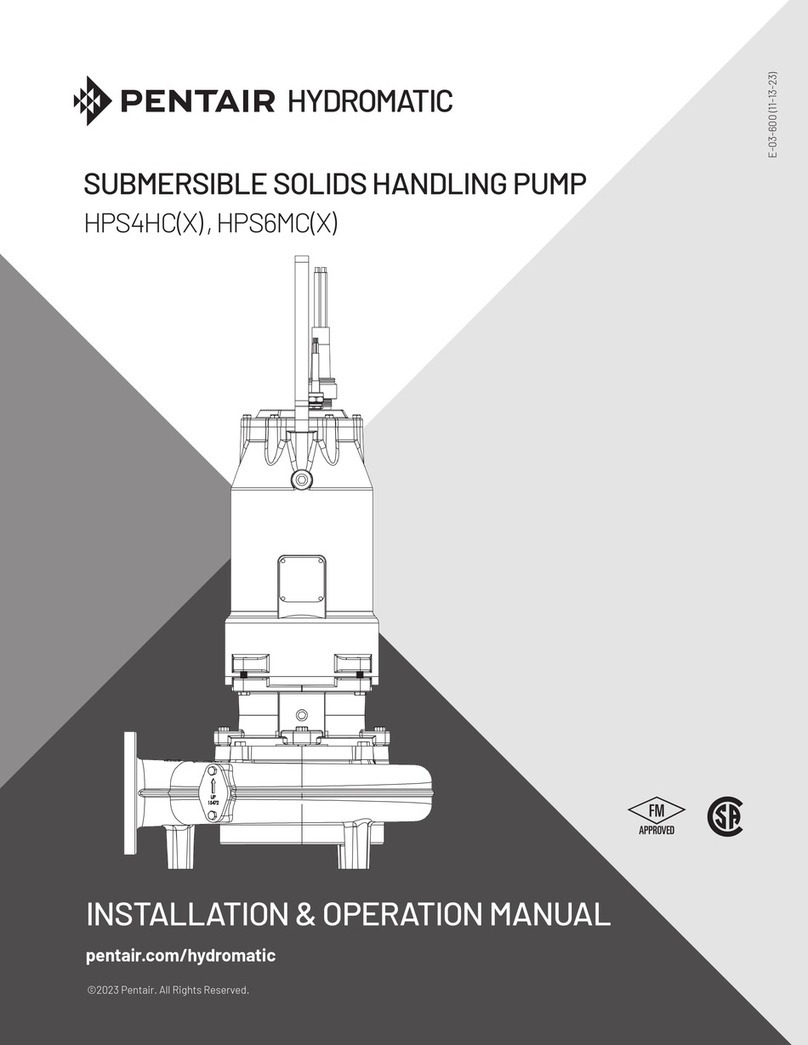

Seal Failure Probes:

All hazardous location submersible

pumps have two factory installed

moisture detectors (seal failure

probes). They are in a normally open

series circuit in the seal chamber.

Under normal operating conditions,

the circuit remains open. If the lower

seal leaks and moisture enters this

chamber, the moisture would settle to

the bottom of the chamber and will

complete the circuit between the

moisture detectors.

This circuit must be connected to a

sensing unit and signaling device. This

is supplied in a Hydromatic®built control

panel.

NOTE: Failure to install such a device

negates all warranties by Hydromatic.

Heat Sensors:

All motors in this family have heat

sensors on or embedded in the motor

winding to detect excessive heat.

This prevents damage to the motor.

If sensor trips due to excessive

winding temperature, the starter in

the panel breaks power to the pump.

Once the sensor resets, the starter is

automatically reset for FM for continued

operation of the pump. This circuitry is

supplied in a Hydromatic control panel.

The sensors are set to trip at 130°C.

NOTE: Failure to install such circuitry

would negate FM approvals and all

warranties by Hydromatic.

Power Cords:

The power cord and heat sensor seal

failure cord are potted into the cord

cap. The cords must not be spliced.

NOTE: Each cable has a green lead.

This is the ground wire and must

be grounded properly per NEC and/

or local codes. Cords should be

inspected for abnormal wear and

replaced accordingly.

Overload Heaters:

If the Hydromatic electrical panel is not

used, starters with 3 leg overload relay

must be supplied on 3 phase pumps.

Each leg is to have an identical heater

sized in accordance with the nameplate

amps on the motor housing. The amp

draw on these submersible motors is

slightly higher than a corresponding

horsepower surface motor, so heaters

must be sized by the nameplate rating.

Capacitor start single phase pumps

have a run and start winding that draws

different currents. To adequately

protect these windings with the

appropriate heaters, consult the

factory.

NOTE: The red lead is always the

start winding of a pump using single

phase.

Pump Installation

Installing Sump Level Controls Float

Controls:

In either simplex, duplex or triplex

systems the lower or turn-off control

is to be set to maintain a minimum level

in the sump. This level shall be no more

than 3-1/4" from the top of the motor

housing down to the surface of the

sewage.

The second or turn-on control is set

above the lower turn-off control. The

exact distance between the two floats

must be a compromise between a

frequent pumping cycle (10 starts per

hour max.) to control septicity, solids

and a slower cycle for energy economy.

This distance should be determined by

the engineer or consulting engineer,

depending on the conditions of

the application.

Installing Pump in Sump:

Before installing the pump in the

sump, lay it on its side and rotate

impeller. Impeller may be slightly

stuck due to factory test water.

The impeller should turn freely.

Do not connect the power until

after this test.

Clean all debris from sump and connect

pump to piping. A check valve must

be installed on each pump. A gate or

plug valve in each pump discharge is

highly recommended. This valve should

be installed on the discharge side of the

check valve so if necessary to service

the check valve, the line pressure can

be cut off. Single pump systems are

sometimes installed without a check

valve where it is desirable to self-drain

the discharge line to prevent freezing.

This can be done only with short

discharge lines; otherwise water will

return to the sump and cause short

cycling of the pump.

Making Electrical Connections:

All electrical wiring must be in

accordance with local codes, and only

competent electricians should make

the installations. Complete wiring

diagrams are glued to the inside

cover of the panel. All wires should be

checked for grounds with an ohmmeter

or Megger® after the connections are

made.