BARCON LHC/PPC

List of contents

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany (06 21) 7 76-0 • USA (330) 4 25 35 55 • Singapore 7 79 90 91 • Internet http://www.pepperl-fuchs.com

Date of Issue 15.12.2000

2

7 Operation of devices without displays . . . . . . . . . . . . . . . . . . . . . . . . 23

7.1 Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7.2 Key functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

7.3 Calibration with pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

7.3.1 Zero point calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7.3.2 Span calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7.4 Calibration without pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7.4.1 Zero point calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7.4.2 Span calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7.4.3 Mounting correction of the sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.5 Integration time (dampening) adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.6 Reset to default . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

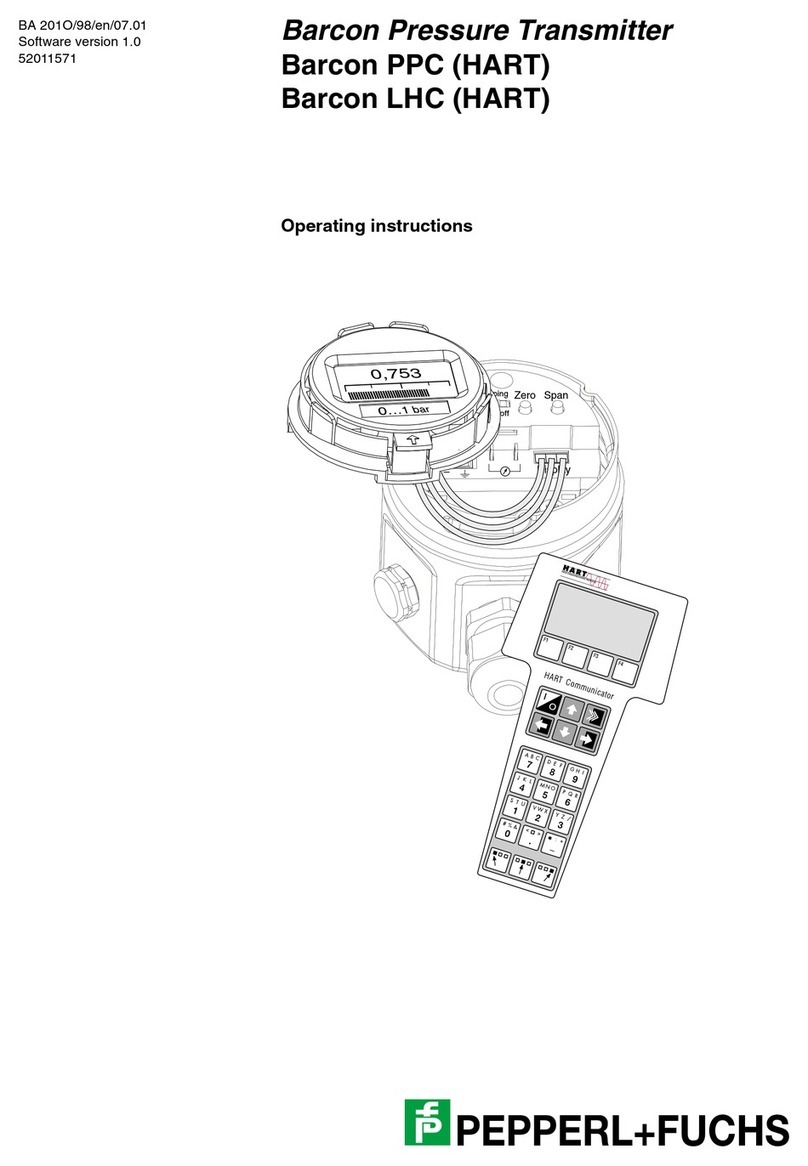

8 Operation of devices with displays . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

8.1 The display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

8.2 Key functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

8.3 The programming mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

8.4 Default data (factory setting) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

8.5 Main menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

8.5.1 Main menu: display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

8.5.2 Main menu: calibration of zero and span (with/without pressure) . . . . . . . . . . . . . .34

8.5.3 Main menu: output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

8.5.4 Main menu: evaluation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

8.5.5 Main menu: language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

8.5.6 Main menu: service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

9 Operation of devices with HART®communication . . . . . . . . . . . . . . 40

9.1 HART®connection options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

9.1.1 Connection HART®Hand-held terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

9.1.2 Connection of the HART®modem for operation via a PC . . . . . . . . . . . . . . . . . . . 41

9.2 Operation via PC using the PACTwareprogram . . . . . . . . . . . . . . . . . . . . . . 43

9.2.1 Register card - Device info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

9.2.2 Register card - Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

9.2.3 Register card - General parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

9.2.4 Register card - Parameter calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

9.2.5 Register card - Parameter output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

9.2.6 Register card - Parameter evaluation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

9.2.7 Menu item - Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

9.2.8 Menu item - Simulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

9.2.9 Menu item - Measuring value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

9.2.10 Menu item - Trend . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

9.2.11 Menu item - Burst mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

9.2.12 Menu item - Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52