2021-04

10

Functional Safety HiD2022*, KFD2-STC5-(Ex)*, KFD2-STV5-(Ex)*

Product Description

KFD2-STV5-1-1, KFD2-STV5-2-1

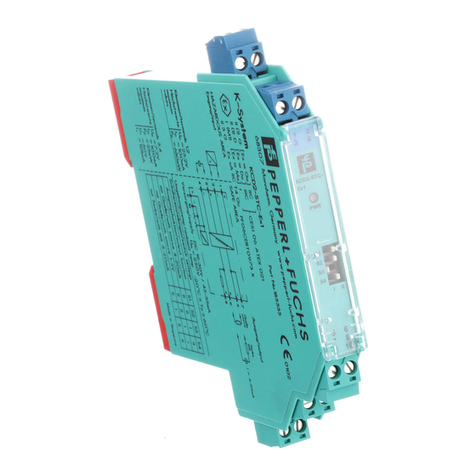

This signal conditioner provides the galvanic isolation between field circuits and control

circuits.

The device supplies 2-wire and 3-wire SMART transmitters, and can also be used

with 2-wire SMART current sources.

It transfers the analog input signal as an isolated current value.

Digital signals may be superimposed on the input signal on the field side or on the control side

and are transferred bi-directionally.

If the HART communication resistance in the loop is too low, the internal resistance can

be used.

Test sockets for the connection of HART communicators are integrated into the terminals

of the device.

KFD2-STV5-Ex1-1, KFD2-STV5-Ex2-1

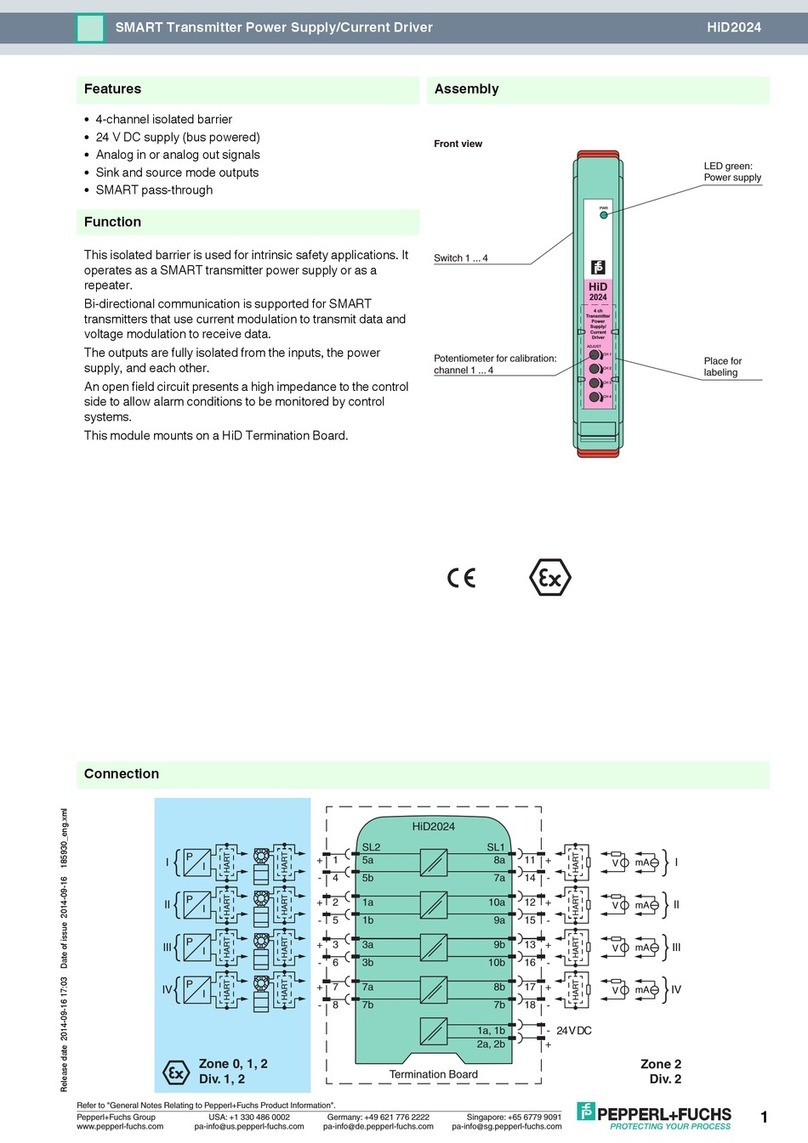

This isolated barrier is used for intrinsic safety applications.

The device supplies 2-wire and 3-wire SMART transmitters, and can also be used

with 2-wire SMART current sources.

The device transfers the analog input signal to the non-hazardous area as an isolated

current value.

Digital signals may be superimposed on the input signal in the hazardous or non-hazardous

area and are transferred bi-directionally.

If the HART communication resistance in the loop is too low, the internal resistance can

be used.

Test sockets for the connection of HART communicators are integrated into the terminals

of the device.

KFD2-STV5-Ex1.2O-1, KFD2-STV5-Ex1.2O-2

This isolated barrier is used for intrinsic safety applications.

The device supplies 2-wire and 3-wire SMART transmitters, and can also be used

with 2-wire SMART current sources.

It transfers the analog input signal to the safe area as two isolated output signals.

Digital signals may be superimposed on the input signal in the hazardous or non-hazardous

area and are transferred bi-directionally.

If the HART communication resistance in the loop is too low, the internal resistance can

be used.

Test sockets for the connection of HART communicators are integrated into the terminals

of the device.

KFD2-STV5-Ex2-1, KFD2-STV5-Ex2-2

This isolated barrier is used for intrinsic safety applications.

The device supplies 2-wire and 3-wire SMART transmitters, and can also be used

with 2-wire SMART current sources.

The device transfers the analog input signal to the non-hazardous area as an isolated

current value.

Digital signals may be superimposed on the input signal in the hazardous or non-hazardous

area and are transferred bi-directionally.

If the HART communication resistance in the loop is too low, the internal resistance can

be used.

Test sockets for the connection of HART communicators are integrated into the terminals

of the device.