2012-07

4

Safety Manual SIL KCD2-STC-(Ex)1.HC(.SP), HiC2025HC

Introduction

1Introduction

1.1 General Information

This manual contains information for application of the device in functional safety

related loops.

The corresponding data sheets, the operating instructions, the system

description, the Declaration of Conformity, the EC-Type-Examination Certificate,

the Functional Safety Assessment and applicable Certificates (see data sheet)

are integral parts of this document.

The documents mentioned are available from www.pepperl-fuchs.com or by

contacting your local Pepperl+Fuchs representative.

Mounting, installation, commissioning, operation, maintenance and disassembly

of any devices may only be carried out by trained, qualified personnel. The

instruction manual must be read and understood.

When it is not possible to correct faults, the devices must be taken out of service

and action taken to protect against accidental use. Devices should only be

repaired directly by the manufacturer. De-activating or bypassing safety functions

or failure to follow the advice given in this manual (causing disturbances or

impairment of safety functions) may cause damage to property, environment or

persons for which Pepperl+Fuchs GmbH will not be liable.

The devices are developed, manufactured and tested according to the relevant

safety standards. They must only be used for the applications described in the

instructions and with specified environmental conditions, and only in connection

with approved external devices.

1.2 Intended Use

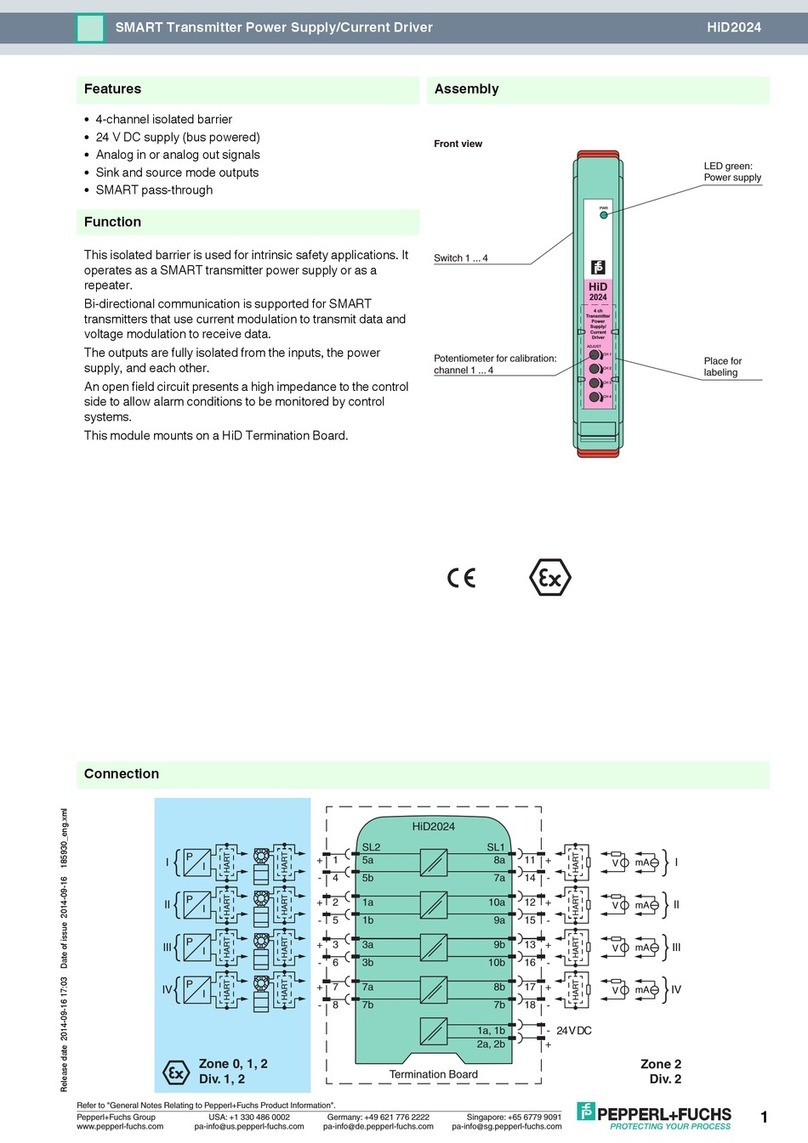

The devices are available as safe area version (KCD2-STC-1.HC(.SP)) where

they can be used as a signal conditioner providing isolation for non-intrinsically

safe applications. Also the devices are available as hazardous area version

(KCD2-STC-Ex1.HC(.SP), HiC2025HC) allowing use as isolated barriers for

intrinsic safety applications.

The device supplies 2-wire transmitters in the field, and can also be used with

current sources.

It transfers the analog input signal to the safe area as an isolated current value.

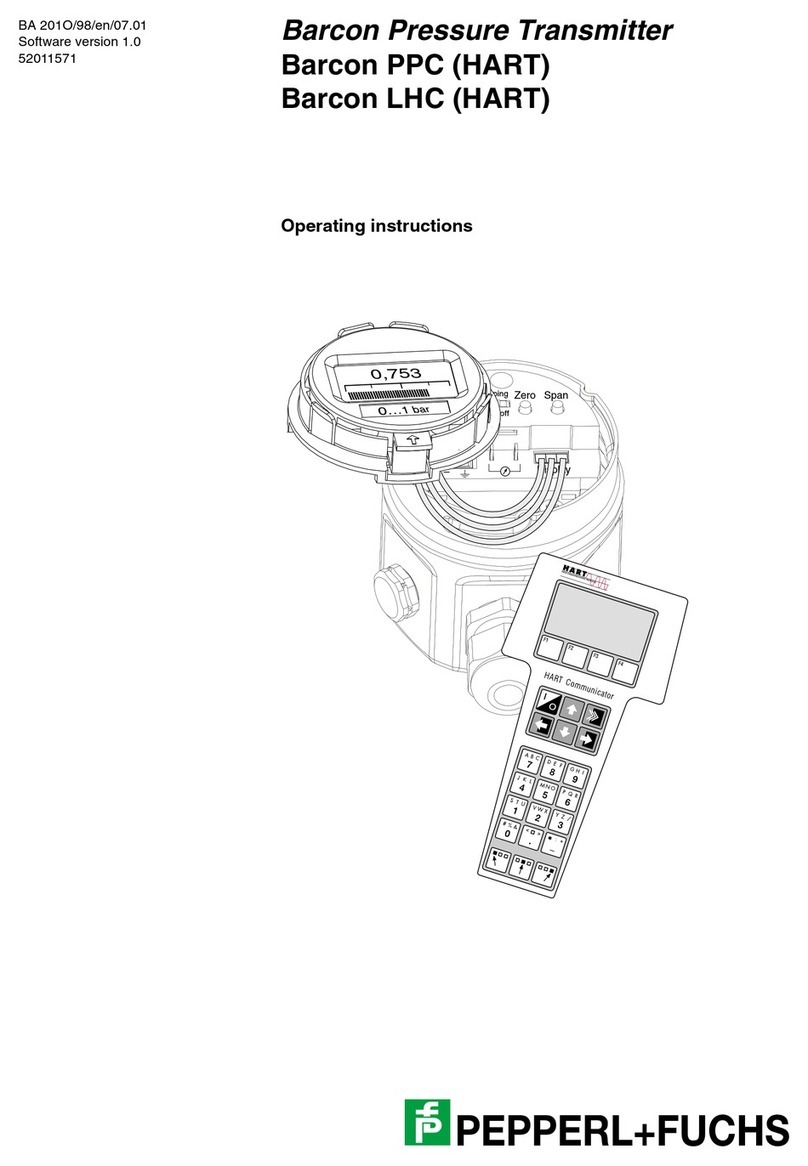

Bi-directional communication is supported for SMART transmitters that use

current modulation to transmit data and voltage modulation to receive data.

The output is selected as a current source, current sink, or voltage source via

DIP switches.

In the KCD2-STC-(Ex)1.HC(.SP) test sockets for the connection of

HART communicators are integrated into the terminals of the device.