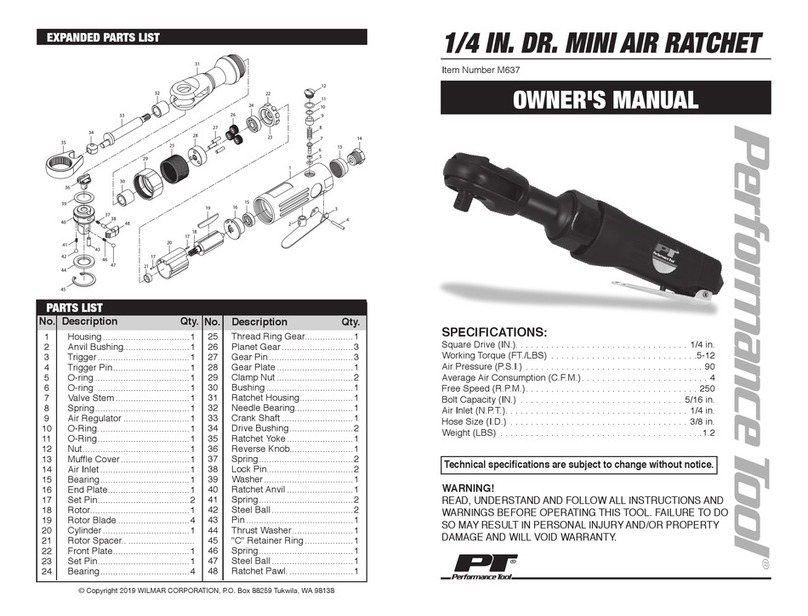

1. This air ratchet is designed to speed productivity, not for high torque applications such

as head bolts, lug nuts, etc. DO NOT USE THIS RATCHET UNDER POWER TO

BREAK FASTENERS LOOSE. Loosen fasteners by hand without depressing throttle.

Once loose, depress throttle to speed fasteners in or out. Always perform final torque

tightening by hand.

2. Use only impact sockets designed for impact wrenches.

3. This ratchet is rated to 5/16" USS bolt size. Rating will decrease for U-Bolts, Long Cap

Screws, Spring Fasteners and rusted or corroded fasteners. All of these factors absorb

power and reduce torque capability.

4. Always use approved eye and ear protection when using air powered tools. If

raising dust/debris, wear a suitable mask. Do not wear loose clothing or jewelry.

5. Always operate tool a safe distance from yourself and others in the work area. Keep

footing and balance at all times.

6. Make sure work piece is secure to allow safe operation of the tool with both hands. Do

not hold the work piece in your hand, lap or against any part of your body.

7. Make sure trigger is in the “off” position before connecting or disconnecting the

tool from air source. Disconnect tool from air source before changing

accessories, performing service and when not in use.

8. Follow air source manufacturer's directions for connection of regulators, filters and other

accessories to air source. Do not install quick couplers directly at tool air inlet. This

causes inlet failure due to excess weight and vibration. Use a whip hose between tool

and quick couplers.

9. DO NOT OVERLOAD! Do not force tool. Match tool capacity to work load requirement.

Use tool within its rated capacity and only for its designated purpose. Overloading air

tools will cause premature wear and/or permanent damage of internal and

external drive parts and will void warranty.

10. Inspect hoses and fittings for wear and damage prior to using tool. Do not carry or drag

tool by the air hose. Keep air hose free from obstruction, twisting and binding.

1. This air ratchet is designed to speed productivity, not for high torque applications such

as head bolts, lug nuts, etc. DO NOT USE THIS RATCHET UNDER POWER TO

BREAK FASTENERS LOOSE. Loosen fasteners by hand without depressing throttle.

Once loose, depress throttle to speed fasteners in or out. Always perform final torque

tightening by hand.

2. This ratchet is rated to 5/16” USS bolt size. Rating will decrease for U-Bolts, Long Cap

Screws, Spring Fasteners and rusted or corroded fasteners. All of these factors absorb

power and reduce torque capability.

3. Use the simplest socket to wrench hook-up. Any additional extensions, u-joints or

adaptors will absorb power and reduce torque capability.

4. Forward/Reverse Lever. Select “F” for Forward (Clockwise) or “R” for Reverse (Counter-

clockwise) operation. Do not attempt to change direction while tool is running.

5. If fastener bogs, slows or binds the tool, use a larger size ratchet tool with a higher

torque rating. Overloading this tool will cause premature wear and/or permanent

damage to internal and external drive parts and will void warranty.

IMPORTANT SAFETY INFORMATION

OPERATION

Clean air of correct air pressure is recommended for the power supply for this tool. A

maximum of 90 PSI at the tool is recommended for most air tools of this class. Check

specifications section for recommended pressure. (Depending on length of air hose and

other circumstances, air pressure at compressor may need to be increased to 100 PSI to

ensure 90 PSI at the tool.)

Water in the air hose and compressor tank contributes to reduced performance and

damage of the air tool. Drain the air tank and filters before each use and as necessary to

keep the air supply dry.

Hose length over 25’ causes loss in line pressure. Increase hose I.D. or increase

compressor pressure to compensate for the pressure loss. Use an in-line pressure

regulator with gauge if air inlet pressure is critical.

AIR SOURCE

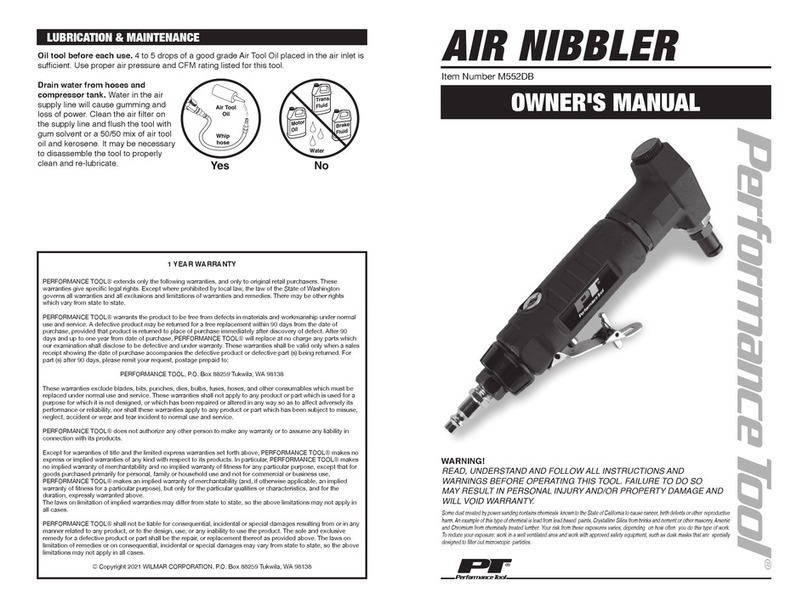

Oil tool before each use. 4 to 5 drops of a good grade Air Tool Oil placed in the air inlet is

sufficient. Use proper air pressure and CFM rating listed for this tool.

Drain water from hoses and compressor tank. Water in the air supply line will cause

gumming and loss of power. Clean the air filter on the supply line and flush the tool with

gum solvent or a 50/50 mix of air tool oil and kerosene. It may be necessary to

disassemble the tool to properly clean and re-lubricate.

LUBRICATION & MAINTENANCE

Forward/Reverse Lever

Air Inlet

Trigger

INSUFFICIENT POWER:

Probable Cause Solution

Dirty or clogged air passages......... Flush and lubricate tool, drain air tank and supply line

Insufficient air supply...................... Increase line pressure, Make sure compressor

matches tool's air pressure and consumption needs

Air leakage...................................... Use PTFE tape at all fittings and joints. Check tool for

worn or damaged O-rings & seals.

Worn/damaged wear & tear parts... Replace as necessary.

Tool matching ................................. Be sure you are using a tool suited for the torque

requirements of the job at hand.

TROUBLESHOOTING

Motor

Oil

Trans.

Fluid

Brake

Fluid

Water

Whip

hose

Air Tool

Oil

YesNo

Check out the collection of air tools & compressors we offer.