LOTUS XS 230 V horizontal continuous mixer / Part 2 Overview, operation and service

Table of contents

Table of contents

1 General information................................... 5

1.1 Information regarding the operating

manual.............................................. 5

1.2 Division............................................. 5

1.3 Keep the manual for future refer-

ence.................................................. 5

1.4 Display of safety and warning

notices.............................................. 6

1.5 Name plate....................................... 6

1.6 EC Declaration of Conformity........... 7

1.7 Quality Control sticker...................... 8

1.8 Intended use.................................... 8

1.8.1 Purpose of fitting block..................... 8

1.8.2 Purpose of flowmeter....................... 9

1.8.3 Purpose of solenoid valve................ 9

2 Technical data............................................. 10

2.1 General information.......................... 10

2.2 Connection values of water.............. 11

2.3 Operating conditions........................ 11

2.4 Sound power level............................ 11

2.5 Vibrations.......................................... 11

3 Transport, packing and storage................ 12

3.1 Safety instructions for transport........ 12

3.2 Transport inspection......................... 13

3.3 Packaging......................................... 13

3.4 Transport in individual parts............. 14

3.5 Transporting a running machine....... 14

4 Description.................................................. 15

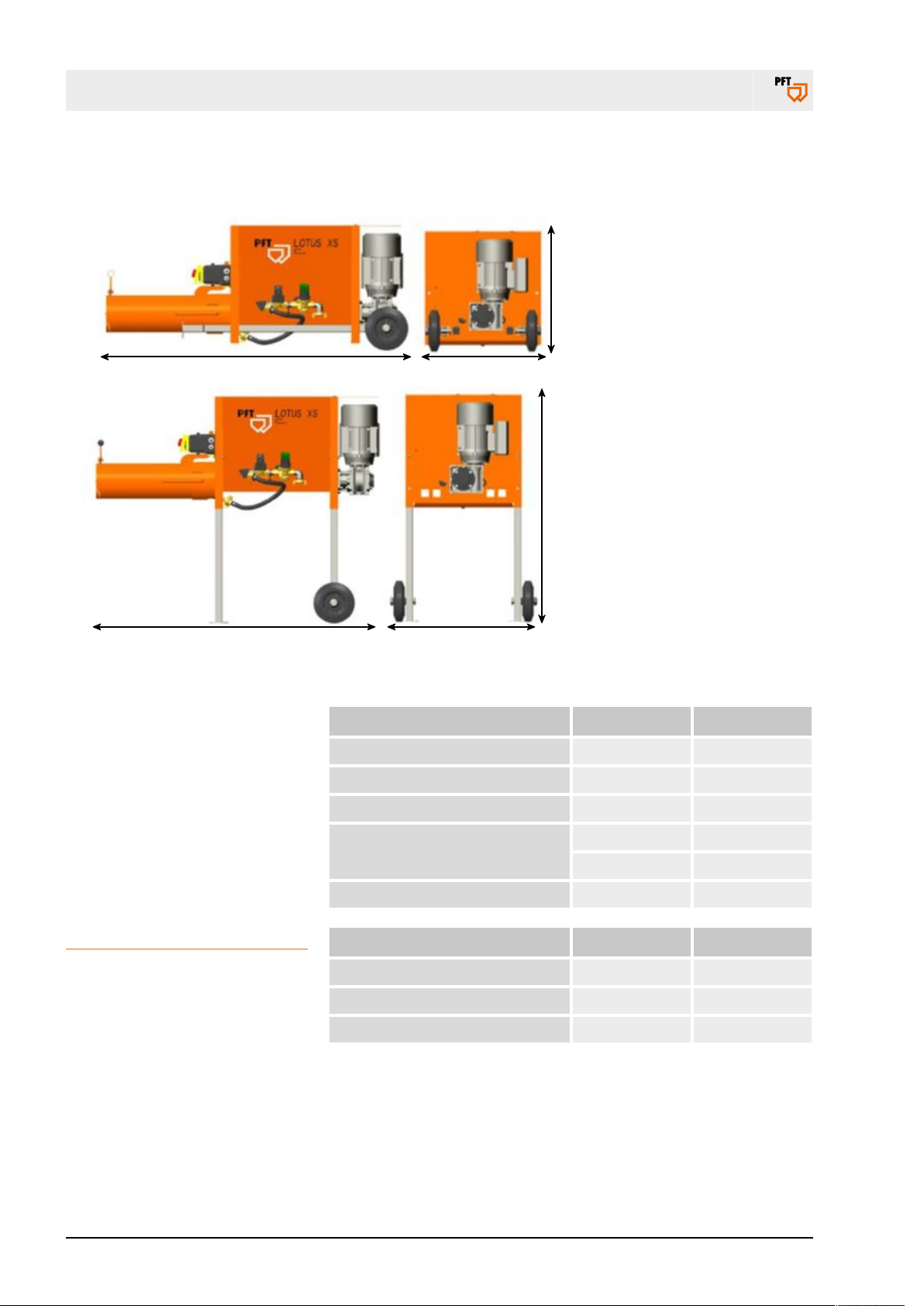

4.1 Overview........................................... 15

4.2 Brief description of the Lotus XS...... 16

4.3 Fields of application......................... 16

4.4 Description of assemblies................ 16

4.4.1 Material hopper with frame............... 17

4.4.2 Mixing tube....................................... 17

4.4.3 Mixing shaft...................................... 18

4.4.4 Water manifold................................. 18

4.5 Connections...................................... 19

4.6 Accessories...................................... 20

5 Operation..................................................... 24

5.1 Safety............................................... 24

5.1.1 Safety rules...................................... 24

5.1.2 Hazardous dusts.............................. 25

5.2 Inspection by machine operator....... 25

5.3 Preparing the machine..................... 25

5.3.1 Risk of injury due to rotating dosing

shaft.................................................. 25

5.3.2 Positioning machine......................... 26

5.3.3 Connecting the power supply........... 26

5.3.4 Connecting the water supply............ 27

5.3.5 Setting pressure reducer.................. 28

5.3.6 Setting the water quantity................. 29

5.3.7 Feeding dry material to the machine 29

5.4 Shutdown in case of emergency...... 29

5.5 Putting the machine into operation... 30

5.5.1 Feeding material to the machine...... 30

5.6 Applying mortar................................ 31

5.7 Interruption of work.......................... 31

5.8 Switching off the machine................ 31

5.9 Action in case of power failure......... 32

5.10 Measures in case of risk of frost....... 32

5.11 Measures to be taken in case of

water outage.................................... 33

5.12 Ending work / cleaning the machine. 33

5.12.1 Cleaning........................................... 33

5.12.2 Secure against restarting................. 33

5.12.3 Removing the mixing tube................ 33

5.12.4 Cleaning the material hopper........... 35

5.12.5 Cleaning the dosing shaft................. 35

5.13 Reaction in the event of faults.......... 36

5.13.1 Safety............................................... 36

5.13.2 Faults................................................ 36

5.13.3 Table of faults................................... 37

6 Maintenance................................................ 38

6.1 Safety............................................... 38

6.1.1 Remove connection cable................ 39

6.2 Environmental protection.................. 39

6.3 Maintenance plan............................. 40

6.4 Maintenance work............................ 40

6.4.1 Implementation by a service techni-

cian................................................... 40

6.4.2 Strainer screen in the water inlet...... 41

6.5 Actions after completed mainte-

nance................................................ 41

6.6 Periodic inspection/expert inspec-

tion.................................................... 41

6.7 Spare parts lists............................... 42

6.8 Accessories...................................... 42

7 Disassembly................................................ 43

7.1 Safety............................................... 43

7.2 Disassembly..................................... 44

page 3 / 48