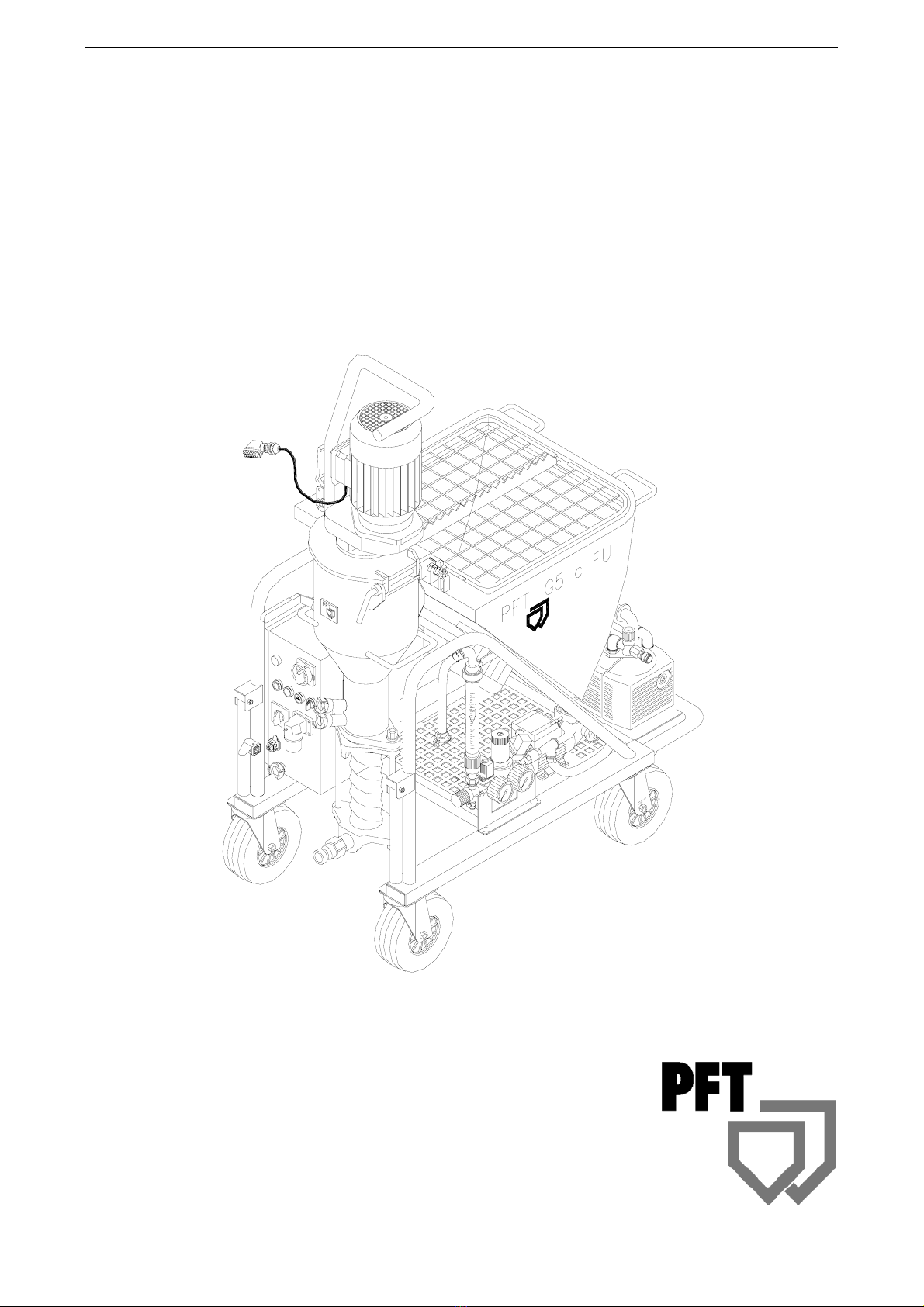

PFT G 5 c FU 230V Operating Manual Issued: 09.2007

Knauf PFT GmbH & Co. KG

4

Dear PFT customer

Congratulations on your purchase. You have made a wise choice as you clearly value the quality

that comes with a brand name product from a reputable company.

The PFT G 5 c FU mixer pump uses state-of-the-art technology. It was functionally designed to be

a reliable aid under rough construction site conditions.

This operating manual should always be stored and kept at hand at the site where the machine is

used. It contains information on the various functions of the machine. Study the operating manual

thoroughly before starting the machine, as we accept no liability for accidents or damage to the

machine caused by incorrect operation.

The PFT G 5 c FU mixer pump will prove to be a trustworthy aid providing it is operated correctly

and handled with care.

It is prohibited to forward this document, even excerpts, without our written authorisation. All

technical specifications, diagrams etc. are subject to copyright law. All rights, errors and

modifications are reserved.

Initial inspection after delivery:

An important task of all technicians delivering the PFT G 5 c FU is the inspection of the machine

settings at the end of the first work phase. The factory settings may change during the initial cycle.

If these changes are not corrected in time, immediately after run-in, problems may arise during

operation.

Following receipt of the PFT G 5 c FU mixer pump and training in regard to it, i.e. after about two

hours of operation, the technician must always carry out the following checks / make the following

settings:

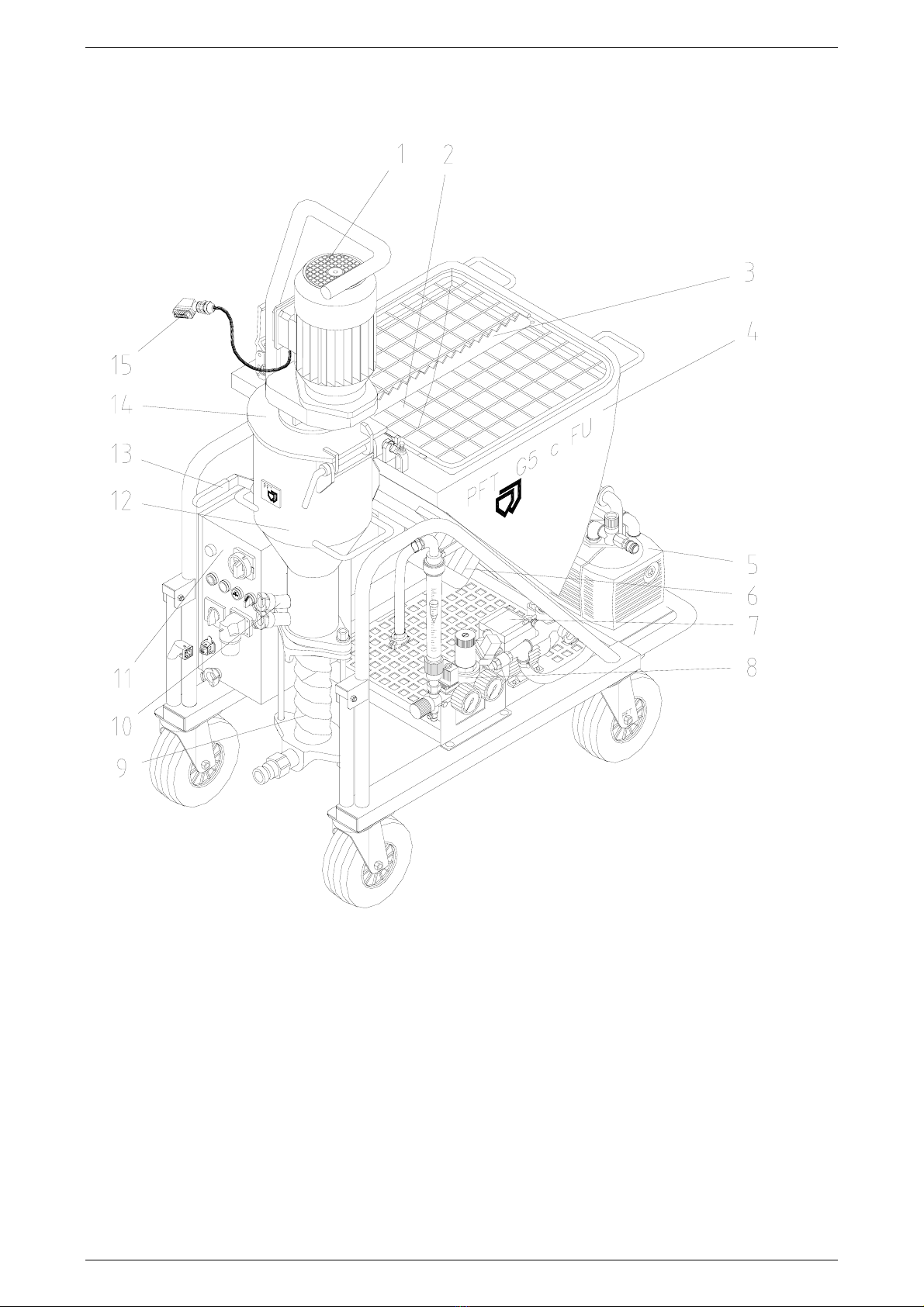

1) Water pressure switch

2) Pump pressure, backpressure

3) Air pressure switch

4) Pressure reducer

It is prohibited to forward this document, even excerpts, without our written authorisation. All technical

specifications, diagrams etc. are subject to copyright law. All rights, errors and modifications are reserved.

© by Knauf PFT GmbH & Co. KG