PFT LOT S XL light 400 V Overview – Operation – Spare Parts Lists

Contents

2017-01-16

3

1

EC Declaration of Conformity ..................... 5

2

Testing .......................................................... 6

2.1 Testing by machine operator ................... 6

2.2 Periodic inspection ................................... 6

3

General information ..................................... 7

3.1 Information regarding the operating

manual ................................................. 7

3.2 Keep the manual for later use.................. 7

3.3 Layout ...................................................... 7

3.4 Spare part lists ......................................... 7

4

Technical data .............................................. 8

4.1 General specifications ............................. 8

4.2 Connected load ........................................ 8

4.3 Connection values for water .................... 9

4.4 Operating requirements ........................... 9

4.5 Sound power level ................................... 9

4.6 Vibrations ................................................. 9

5

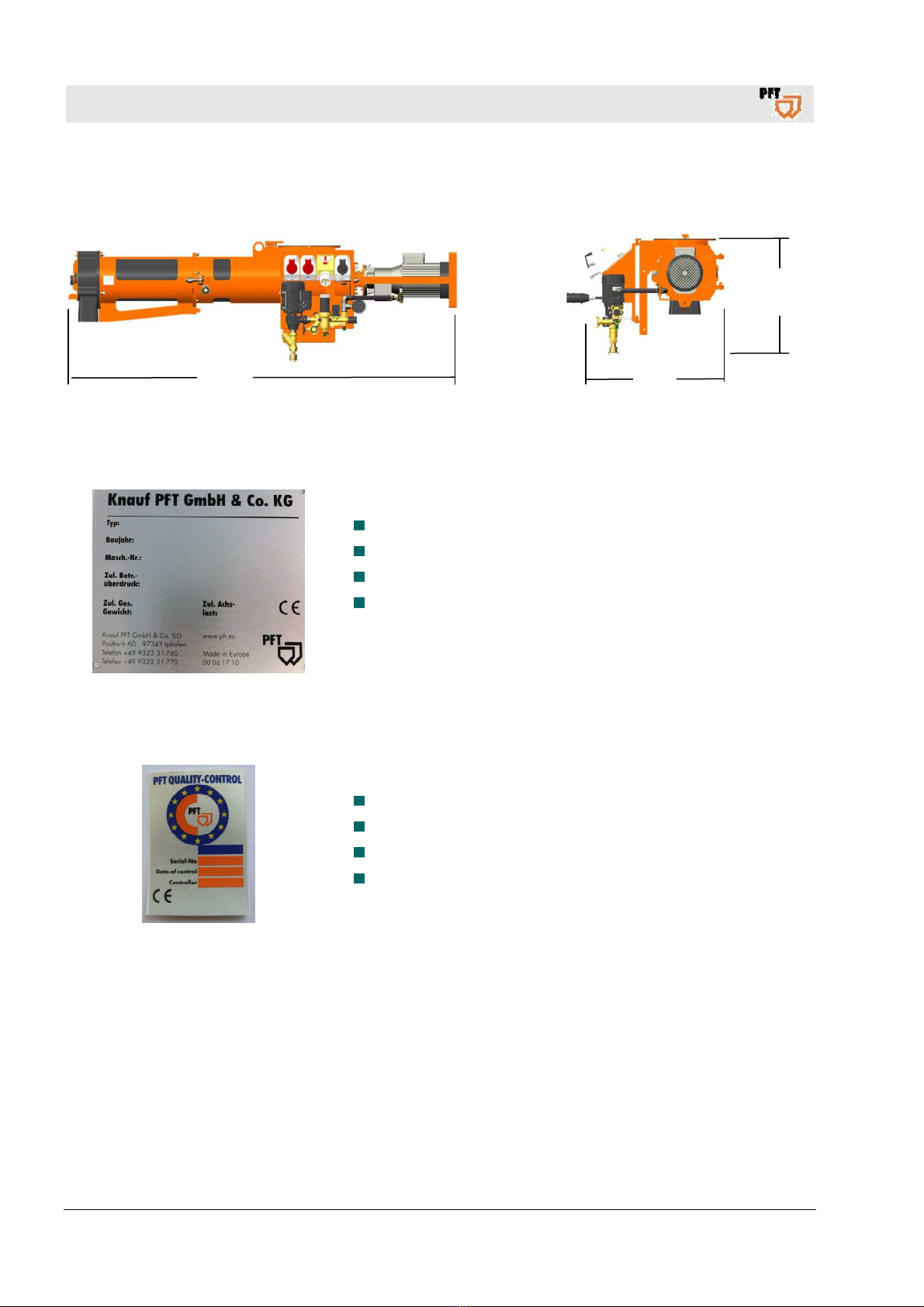

Dimension sheet for Lotus XL .................. 10

5.1 Type plate .............................................. 10

6

Quality control sticker ............................... 10

7

Design of LOTUS XL .................................. 11

7.1 Overview of LOT S XL silo light 400 V . 11

7.2 Overview of LOT S XL silo light 400 V

with water pump ................................ 12

8

Su assem lies ........................................... 13

8.1 Gear motor ............................................. 13

8.2 Middle body ............................................ 13

8.3 Mixing shaft / dosing shaft ..................... 13

8.4 Mixing tube with outlet ........................... 13

9

Description of su assem lies .................. 14

9.1 Overview of control unit without water

pump .................................................. 14

9.2 Overview of control unit with water

pump .................................................. 14

10

Connections ............................................... 15

10.1 Electrical connection ............................ 15

10.2 Water connection ................................. 15

11

Accessories ................................................ 16

11.1 Necessary accessories ........................ 16

11.2 Recommended accessories ................. 16

12

Brief description ......................................... 17

13

Material ........................................................ 18

13.1 Areas of application .............................. 18

14

Safety regulations ...................................... 19

15

Transport, packaging and storage ........... 19

15.1 Safety instructions for transport ........... 19

15.2 Transport checklist ............................... 20

15.3 Transport in individual parts ................. 20

15.4 Transportation of machines already

operating ............................................ 20

16

Packaging .................................................... 21

17

Operation ..................................................... 21

17.1 Safety ................................................... 21

18

Preparation of the machine ....................... 22

18.1 Fastening the LOT S XL to the silo ..... 23

18.2 Connection to the 400 V power supply 23

18.3 Checking the individual connector

plugs ................................................... 23

18.4 Water supply connection ...................... 24

18.5 Water from a water barrel ..................... 25

19

Setting the water factor ............................. 25

19.1 Presetting the water flow rate ............... 25

20

Putting the machine into operation .......... 26

20.1 Hazardous dust .................................... 26

20.2 Switching on the machine .................... 26

20.3 Changing the direction of rotation at

the main switch .................................. 27

21

Applying mortar .......................................... 28