P.O. Box 1306, Newport Beach, California 92663 • Phone: 714-751-0488 • Fax: 714-957-1621 • E-Mail: techservice@newmarpower.com

www.newmarpower.com

4

PERSONAL PRECAUTIONS

1. Someone should be within range of your voice or close enough

to come to your aid when you work near a lead-acid battery.

2. Have plenty of fresh water and soap nearby in case battery

acid contacts skin, clothing or eyes.

3. Wear complete eye protection and clothing protection. Avoid

touching your eyes while working near a battery.

4. If battery acid contacts skin or clothing, wash immediately with

soap and water. If battery acid enters the eye, immediately flood

the eye with running cold water for at least 10 minutes and get

medical attention immediately.

5. NEVER smoke or allow a spark or flame in the vicinity of the

battery or engine.

6. Be extra cautious to reduce the risk of dropping a metal tool

onto the battery. It might spark or short-circuit the battery or other

electrical part and cause an explosion.

7. Remove personal metal items such as rings, bracelets, necklaces

and watches when working with a lead-acid battery. A lead-acid

battery can produce a short-circuit current high enough to weld a

ring or the like to metal, causing a severe burn.

8. Use the battery charger for charging gel-cell, AGM or flooded

lead-acid batteries only. It is not intended to supply power to a low

voltage electrical system other than in a starter-motor application.

Do not use the charger for charging dry-cell batteries that are

commonly used with home appliances. These batteries may burst

and cause injury to persons and damage to property.

9. NEVER charge a frozen battery.

PREPARING TO CHARGE

1. Be sure the area around the battery is well ventilated.

2. Clean battery terminals. Be careful to keep corrosion from

coming in contact with eyes.

3. Add distilled water in each cell until battery acid reaches level

specified by battery manufacturer. This helps purge excessive gas

from cells. Do not overfill. For a battery without cell caps, carefully

follow manufacturer’s recharging instructions.

4. Study all battery manufacturers’ specific precautions such

as removing or not removing cell caps while charging and

recommended rates of charge.

GROUNDING AND A.C. POWER CORD CONNECTION

1. The charger should be grounded to reduce the risk of electric

shock.

(For marine applications only) EXTERNAL CONNECTIONS TO THE

CHARGER SHALL COMPLY WITH UL RECOMMENDATIONS AND/

OR UNITED STATES COAST GUARD ELECTRICAL REGULATIONS

(33CFR183, SUB-PART I)

(For marine applications only) THE INSTALLATION AND

PROTECTION OF VESSEL WIRING ASSOCIATED WITH BATTERY

CHARGERS SHALL COMPLY WITH ABYC STANDARDS; E-11) AC

& DC ELECTRICAL SYSTEMS ON BOATS, AND A-31) BATTERY

CHARGERS & INVERTERS.

III) INSTALLATION

A) Materials Provided

1) Installation/Operation manual

1) Clear plastic output terminal cover

The Phase Three charger is provided completely assembled and

ready for installation. The installer must provide four suitable 1/4”

mounting screws/washers, as well as D.C. output wiring and

connectors. Proper sizes and gauges for the wire and connectors

are noted in section III-D following.

B) Location

The charger should be mounted on a wall, bulkhead or other

suitable mounting surface as close to the batteries to be charged

as possible. Do not mount the charger directly over the batteries

as battery fumes may cause excessive corrosion. WARNING:

The charger is not ignition protected so it must not be located

in an area where ignition protected equipment is required. The

area should be well ventilated and free from excessive moisture,

exhaust manifolds and battery fumes.

Vertical mounting is preferred. However, horizontal mounting is

acceptable where absolutely necessary. Do not mount the charger

where water, spray or condensation can occur, as this will shorten

charger life. It should not be located where there is a possibility

of dust or debris being drawn into the unit through the fan. A

minimum of 2” clearance around the charger is recommended for

proper cooling.

If the charger is located in an extreme heat area, such as an

unventilated engine room, and maximum operating temperature

is exceeded, an automatic thermal shutdown protection circuit

will turn the charger completely off. Thermal cycling will shorten

the life of the charger, so if this condition occurs repeatedly, the

charger should be relocated. For optimum performance and

longer life the charger should not be located in an area of extreme

high temperature.

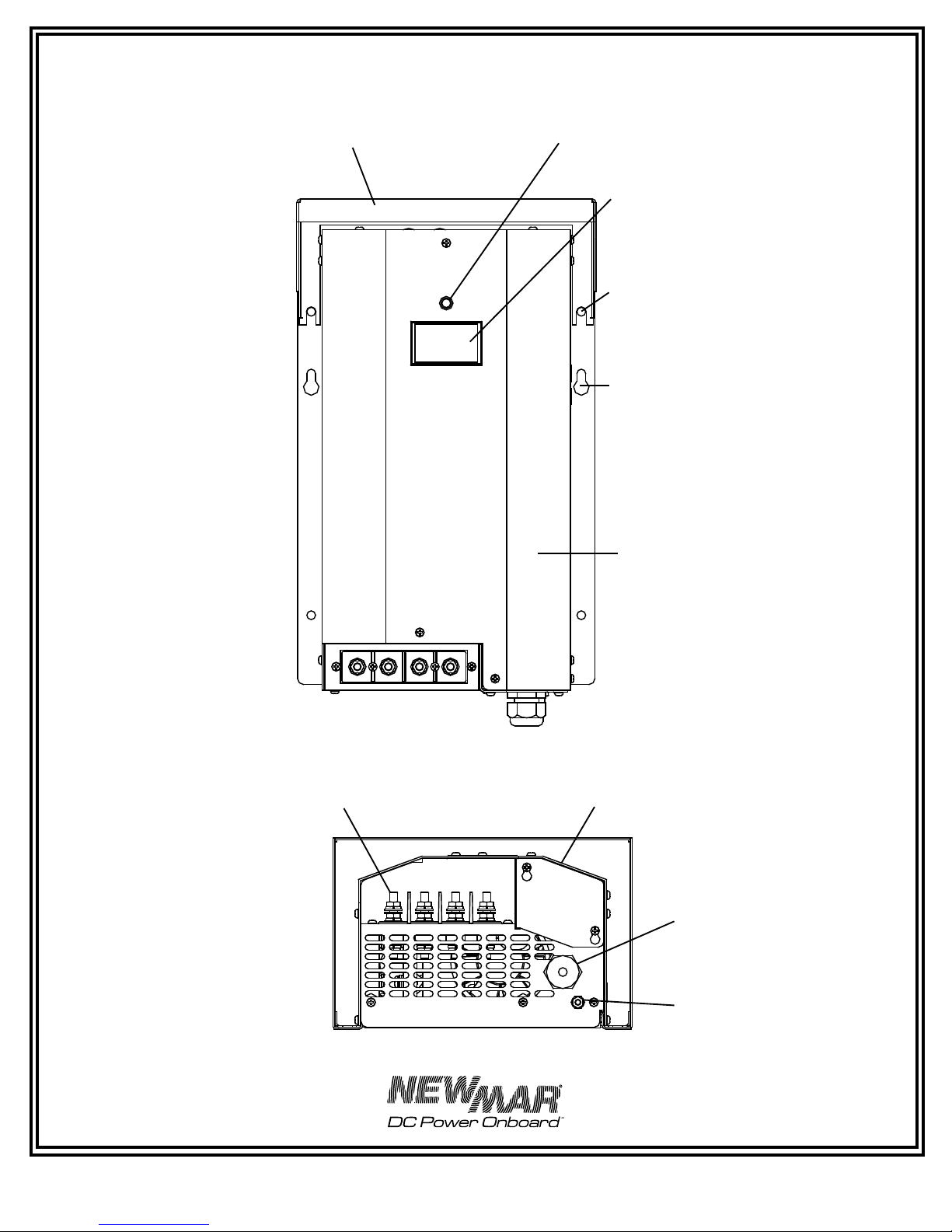

C) Mounting

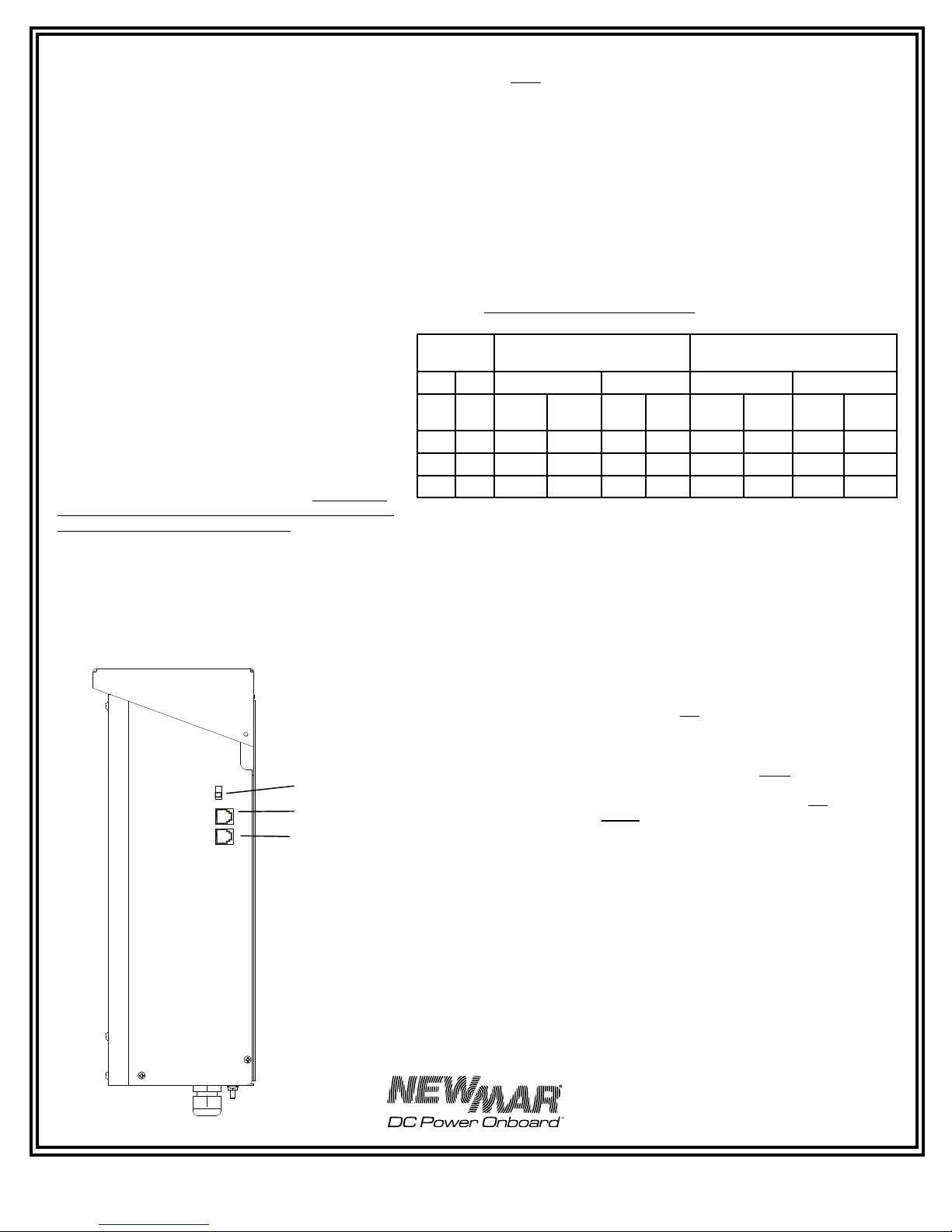

Important Pre-Installation Note: The wiring access port for A.C.

input is located on the bottom of the charger. If the factory-installed

A.C. cord must be changed for any reason, this should be done

before mounting, as access will be difficult afterwards. Also, the

drip shield will need to be removed prior to setting the gel/lead

acid selector or installing the optional temperature compensation

probe. The drip shield is removable with the charger mounted,

but if there is limited overhead clearance, the installer may wish

to accomplish these tasks also, prior to mounting the charger. For

information on these installation procedures, refer to sections III-F

and IV-E.

The charger may be mounted on either a metal or non-metal

surface*. You will require four screws (wood or machine screws,

depending on mounting surface) with washers, sized for 1/4”

holes, to mount the charger, plus two temporary holding screws.

Note that, in addition to the four permanent mounting holes in the

flanges, there is a hole in each mounting flange which is “keyhole”

shaped. This is provided to ease vertical installation.