2

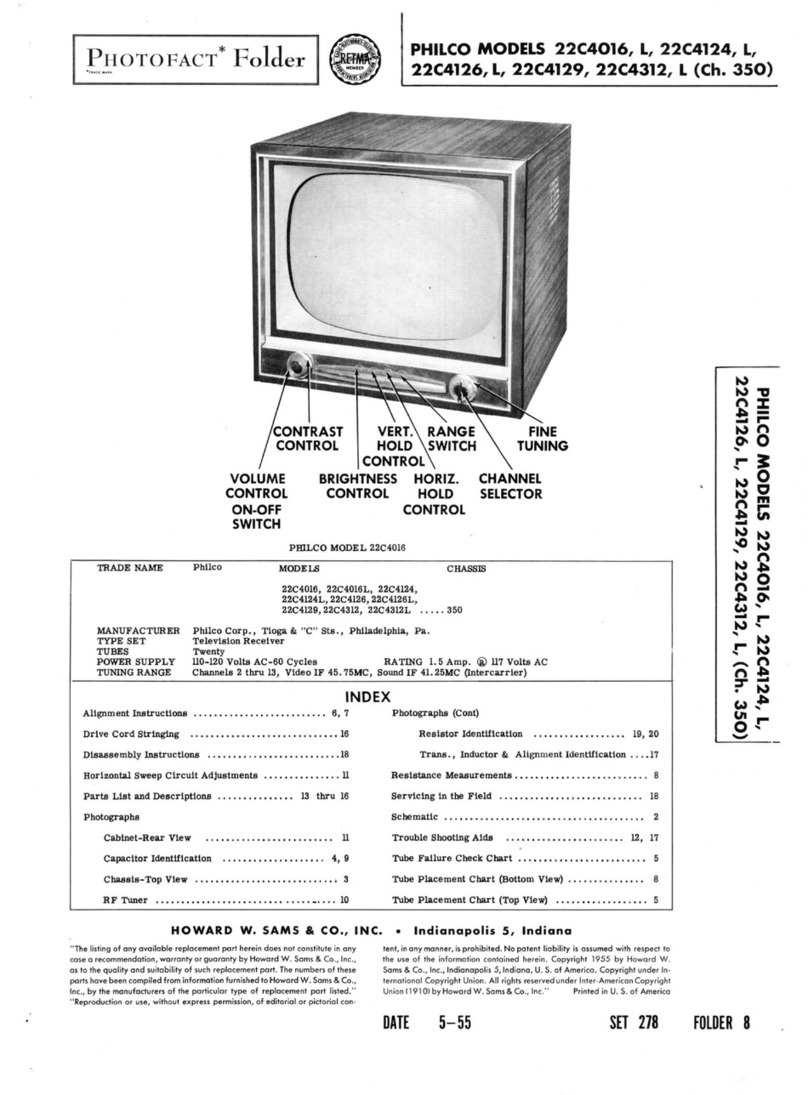

PH-1470

IMPORTANT SERVICE SAFETY PRECAUTION

Service work should be performed only by qualified service technicians who are thoroughly

familiar with all safety checks and the servicing guidelines which follow:

4A 125V

SERVICING OF HIGH VOLTAGE SYSTEM

AND PICTURE TUBE

When servicing the high voltage system,

remove the static charge by connecting a

10k ohm resistor in series with an insulated

wire (such as a test probe) between the pic-

ture tube ground and the anode lead. (AC

line cord should be disconnected from AC

outlet.)

1. Picture tube in this receiv er emplo ys integ ral

implosion protection.

2.Replace with tube of the same type number for

continued safety.

3. Do not lift picture tube by the neck.

4.Handle the picture tube only when wear ing

shatterproof goggles and after discharging the high

voltage anode completely.

X-RADIATION AND HIGH VOLTAGE LIMITS

1. Be sure all service personnel are aware of the

procedures and instructions covering X-r adiation.

The only potential source of X-ray in current solid

state TV receivers is the picture tube.However, the

picture tube does not emit measurab le X-Ra y

radiation, if the high voltage is as specified in the

"High Voltage Check" instructions.

It is only when high voltage is excessive that X-

radiation is capable of penetrating the shell of the

picture tube including the lead in the glass material.

The important precaution is to keep the high voltage

below the maximum level specified.

2. It is essential that servicemen have available at all

times an accurate high voltage meter.

The calibration of this meter should be checked

periodically.

3.High voltage should always be kept at the rated value

-no higher.Operation at higher voltages may cause

a failure of the picture tube or high voltage circuitry

and;also, under certain conditions, may produce

radiation in exceeding of desirable levels.

4.When the high voltage regulator is operating properly

there is no possibility of an X-radiation problem.

Every time a color chassis is serviced, the brightness

should be tested while monitoring the high voltage

with a meter to be certain that the high voltage does

not exceed the specified value and that it is regulating

correctly.

5. Do not use a picture tube other than that specified

or make unrecommended circuit modifications to the

high voltage circuitry.

6.When troubleshooting and taking test measurements

on a receiver with excessive high voltage, avoid being

unnecessarily close to the receiver.

Do not operate the receiver longer than is necessary

to locate the cause of excessive voltage.

WARNING

1. For continued safety, no modification of any circuit

should be attempted.

2. Disconnect AC power before servicing.

3.Semiconductor heat sinks are potential shock

hazards when the chassis is operating.

4. The chassis in this receiver has two ground systems

which are separated by insulating material.The non-

isolated (hot) ground system is for the B+ voltage

regulator circuit and the horizontal output circuit.The

isolated ground system is for the low B+ DC voltages

and the secondar y circuit of the high voltage

transformer.

To prevent electrical shock use an isolation

transformer between the line cord and power

receptacle, when servicing this chassis.

CAUTION: FOR CONTINUED

PROTECTION AGAINST A

RISK OF FIRE, REPLACE

ONLY WITH SAME TYPE 4A-

125V FUSE.