Philips HI 915 User manual

Other Philips Iron manuals

Philips

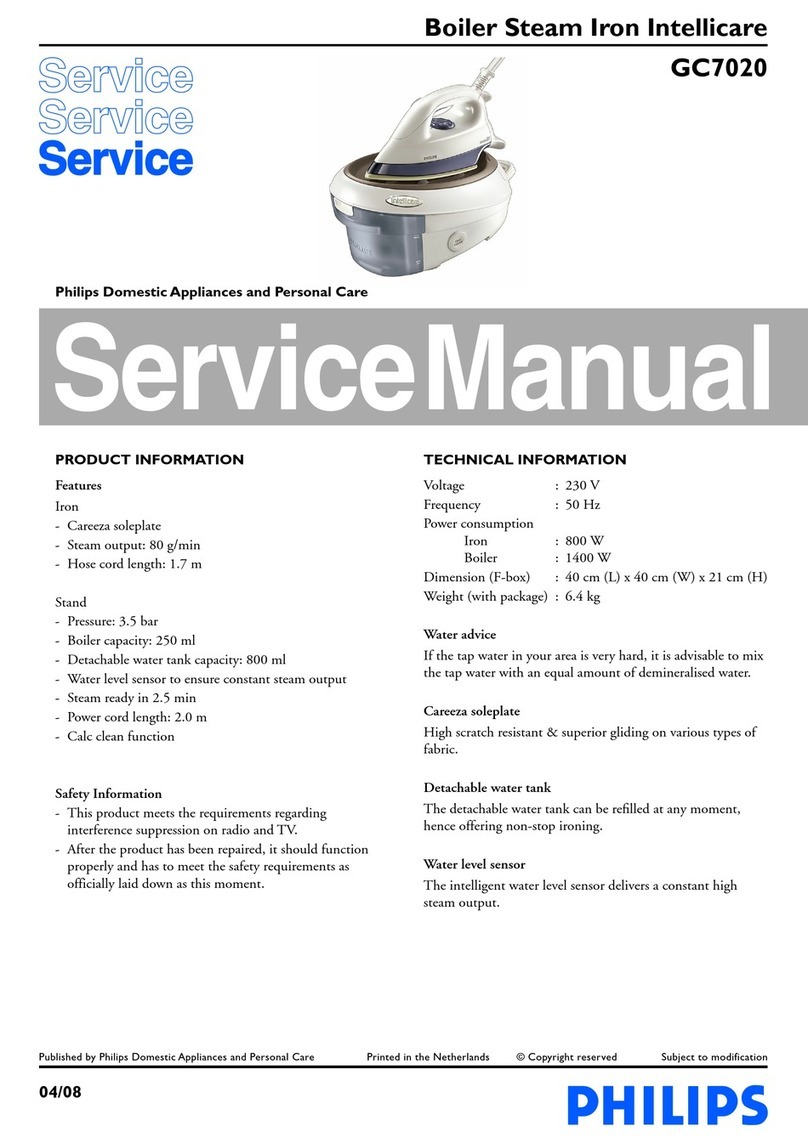

Philips Intellicare GC7020 User manual

Philips

Philips COMFORT GC1121 User manual

Philips

Philips ELANCE GC3006 User manual

Philips

Philips GC140 Series User manual

Philips

Philips GC9682 User manual

Philips

Philips GC4711/07 User manual

Philips

Philips GC4938/20 User manual

Philips

Philips GC2960/07 User manual

Philips

Philips GC6600 series User manual

Philips

Philips Azur 4800 GC4845 User manual

Philips

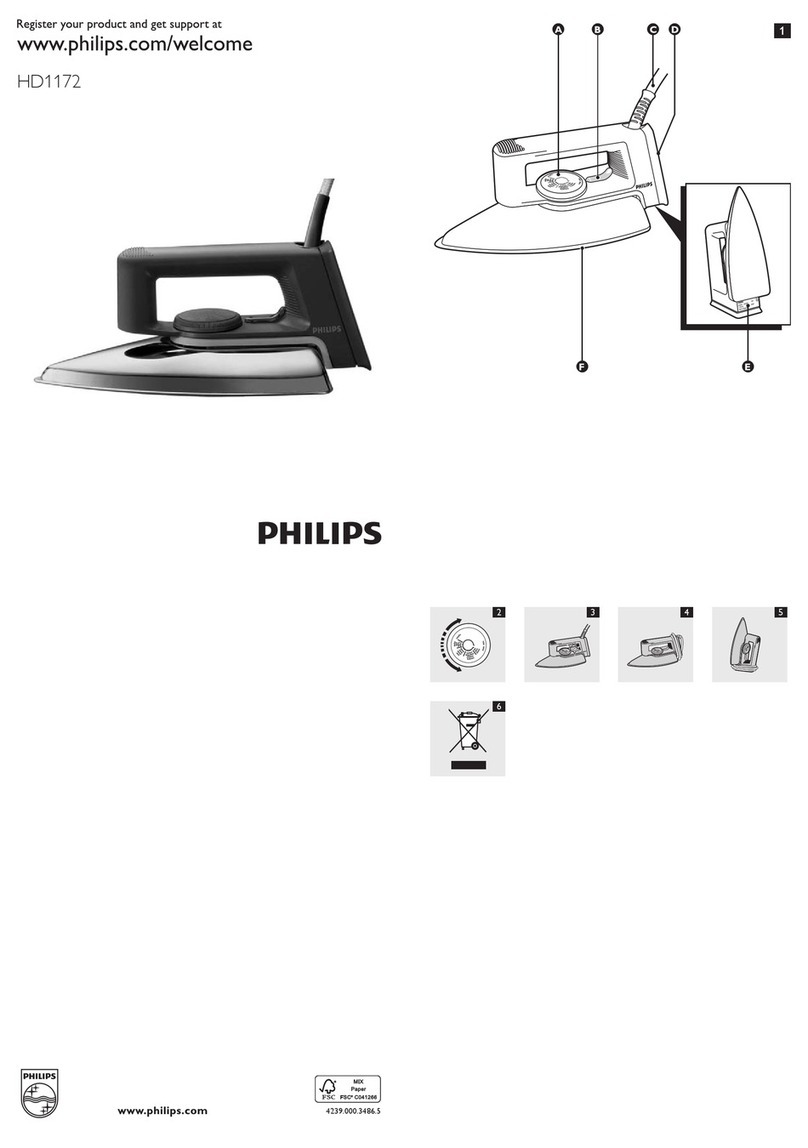

Philips HD1172/00 User manual

Philips

Philips GC7705 User manual

Philips

Philips Intellicare GC8080 User manual

Philips

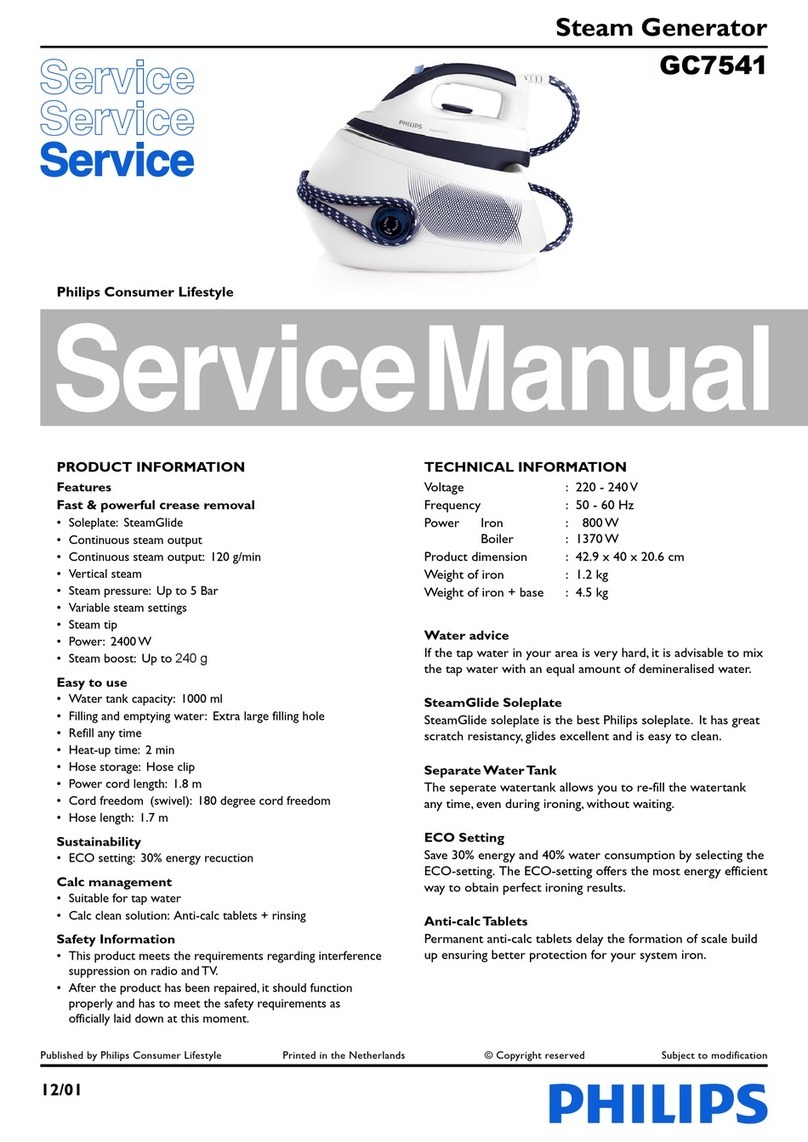

Philips GC7541 User manual

Philips

Philips Comfort LongLife GC1610 User manual

Philips

Philips HI901/03 User manual

Philips

Philips GC4400 series User manual

Philips

Philips GC9247 User manual

Philips

Philips GC7000 Series User manual

Philips

Philips EasyCare GC8300 Series User manual