NOTE: Detailed information on the PIKO SmartDecoder XP 5.1 is available as a PDF le on our Webshop

on the page of the respective item number. The le contains a full description of all functions and

operating possibilities for the new SmartDecoder XP 5.1.

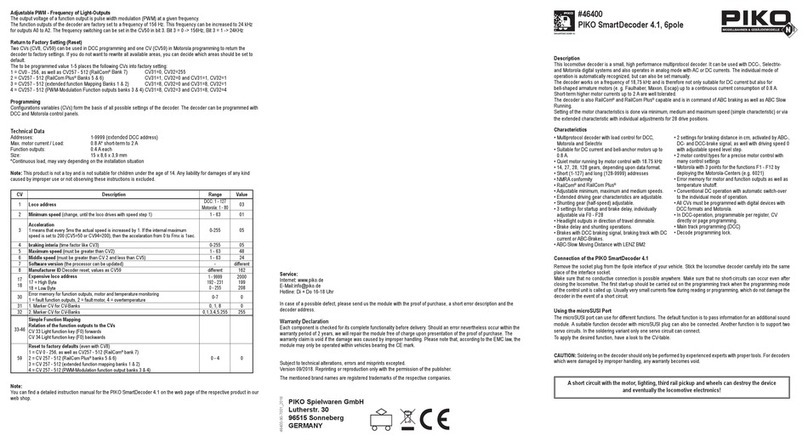

Description

This PIKO SmartDecoder XP 5.1 with 8-pin interface according to NEM652 is a compact, yet powerful multi-protocol

decoder. It complies with the current RCN standards in all areas and can be used in DCC, mfx® and Motorola® digital

systems. The decoder can be used on DC or AC analog layouts. It automatically senses what operating mode is used

on your layout and is RailCom®/RailCom Plus® compatible. The SmartDecoder XP 5.1 features several programmable

braking distance functions in addition to numerous other programmable functions.

The load-controlled decoder operates with an auto-adaptive motor control and is therefore suitable not only for

DC motors, but also for bell armature motors up to a continuous current consumption of 1.2 A. The decoder will

also tolerate a temporary current draw up to 2 Amps. The motor speed table can be set using the minimum,

median, and maximum motor speed (simple curve), or by the user-programable 28-speed step extended curve.

The decoder has two directional light outputs and an additional special function output, which can be activated via

function keys up to F68 (DCC). The switching (shunting) gear, with extended slow speed range, the three possible

starting and braking delays, are also switchable via function keys. Due to the advanced power management the

PIKO SmartDecoder XP 5.1 is supported in case of brief loss of power is supported.

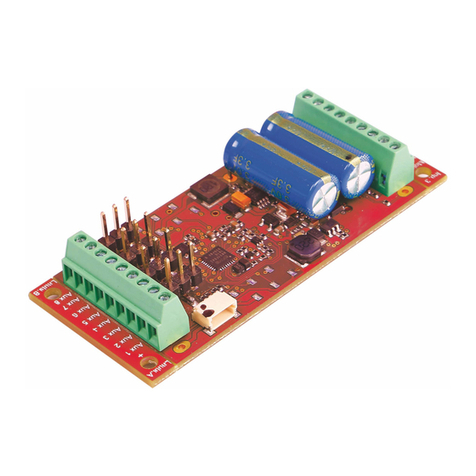

Installing the PIKO SmartDecoder XP 5.1

Remove the jumper plug from your model’s NEM 652 interface. At the same place insert the 8-pin plug of the decoder

carefully into the interface socket. Please note the coding of PIN 1 note. If the plug is turned 180°, the locomotive will run

in the wrong direction and the light will not work. Check for crossed wires and short circuits before and after reinstalling

the shell. Place the model on your programming track with programming mode activated on your DCC system. During

programming or when reading the model’s DCC address, a small amount of current will ow through the model, which

does not affect the decoder; even in the event of a short circuit.

Special function A1

The special function output A1 of the PIKO SmartDecoder XP 5.1 can only be used if the desired consumer is already

connected to the NEM 652 interface in the vehicle, or if there are solder pads on the main board.

First-time use of the decoder (state of delivery)

Enter address 3 on your DCC control system. Depending on your DCC system‘s data format, the decoder will

operate using 28 speed steps or in Motorola® mode. When using a RailCom Plus®-enabled DCC system or with

an mfx®-capable system, the decoder is recognized in a few seconds and can be operated immediately. If the

decoder is used on a conventional analog layout, it can be controlled with a DC or AC power pack. The decoder will

automatically detect the layout’s operating mode.

NOTE: In DC analog mode, your model will only start at a higher voltage than what you may accustomed to when

operating analog models. You will need to turn the throttle up for the model to start operating.

Function outputs in analog mode

It is possible to program the decoder so that function keys F0 - F12 (as they are assigned in the function mapping) can

also be activated in analog mode. To do this, CVs 13 & 14 must rst be programmed with a DCC central control unit.

The corresponding values can be found in the CV table of the detailed operating instructions.

The light function (F0) and output A1 (F1) are switched on ex works.

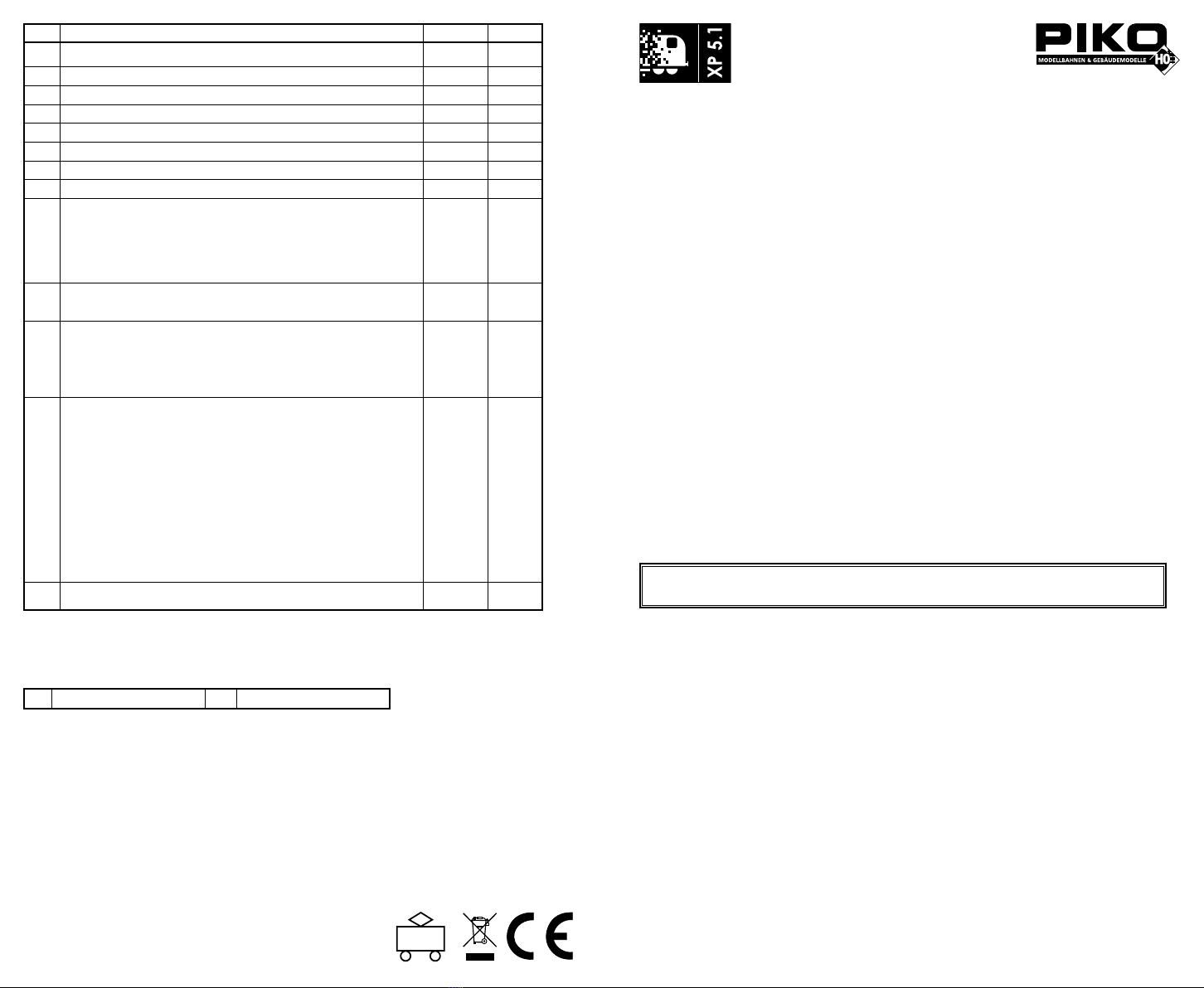

* factory set values

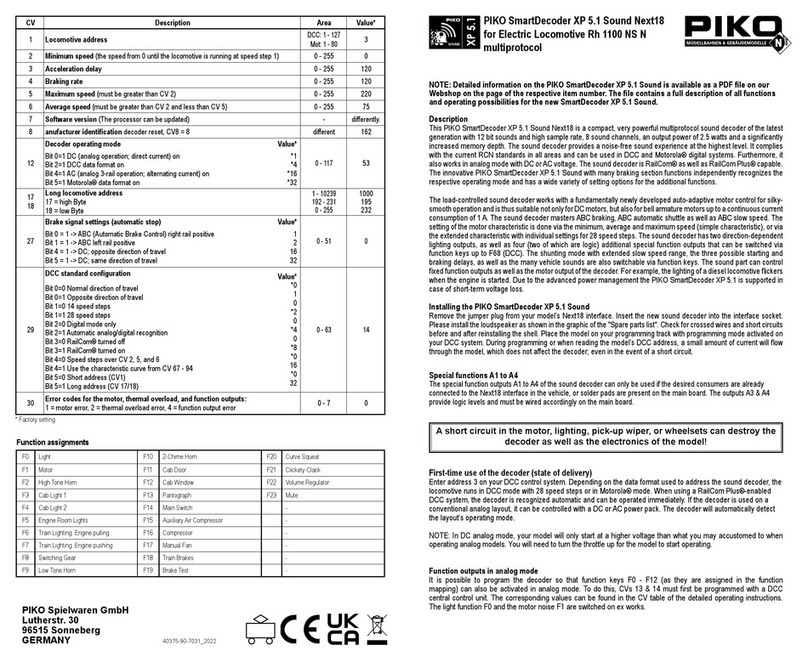

CV Description Area Value*

1Locomotive address

DCC: 1 - 127

Motorola

®

: 1 - 80

3

2Minimum speed (the speed from 0 until the locomotive is running at speed step 1) 0 - 255 0

3Acceleration delay 0 - 255 30

4Braking delay 0 - 255 30

5Maximum speed (must be greater than CV 2) 0 - 255 200

6Average speed (must be greater than CV 2 and less than CV 5) 0 - 255 100

7Software version (The processor can be updated) - differently

8Manufacturer's ID Decoderreset CV8 = 8

different

162

12

Decoder operating mode

Bit 0=1 DC (analog operation; direct current) on

Bit 2=1 DCC data format on

Bit 4=1 AC (analog 3-rail operation; alternating current) on

Bit 5=1 Motorola® data format on

Bit 6=1 mfx® data format on

0 - 117

117

17

18

Long locomotive address

17 = high Byte

18 = low Byte

1 - 10239

192 - 231

0 - 255

1000

195

232

27

Brake signal settings (automatic stop)

Bit 0 = 1 -> ABC (Automatic Brake Control) right rail positive

Bit 1 = 1 -> ABC left rail positive

Bit 4 = 1 -> DC; opposite direction of travel

Bit 5 = 1 -> DC; same direction of travel

0 - 51

0

29

DCC standard conguration

Bit 0=0 Normal direction of travel

Bit 0=1 Opposite direction of travel

Bit 1=0 14 speed steps

Bit 1=1 28 speed steps

Bit 2=0 Digital mode only

Bit 2=1 Automatic analog/digital recognition

Bit 3=0 RailCom® turned off

Bit 3=1 RailCom® turned on

Bit 4=0 Speed steps over CV 2, 5, and 6

Bit 4=1 Use the characteristic curve from CV 67 - 94

Bit 5=0 Short address (CV1)

Bit 5=1 Long address (CV 17/18)

0-63 14

30 Error codes for the motor, thermal overload, and function outputs:

1 = motor error, 2 = thermal overload error, 4 = function output error 0-7 0

Value

*0

1

0

*2

0

*4

Value

*1

*4

*16

*32

*64

Value

1

2

16

32

0

*8

*0

16

*0

32

A short circuit in the motor, lighting, pick-up wiper, or wheelsets can destroy the

decoder as well as the electronics of the model!

#56503

PIKO

multiprotocol

SmartDecoder XP 5.1 NEM652

mfx® capability included

56503-90-7001_2021

PIKO Spielwaren GmbH

Lutherstr. 30

96515 Sonneberg

GERMANY

Assignment of the function keys

F0 Light F1 Function output A1