1

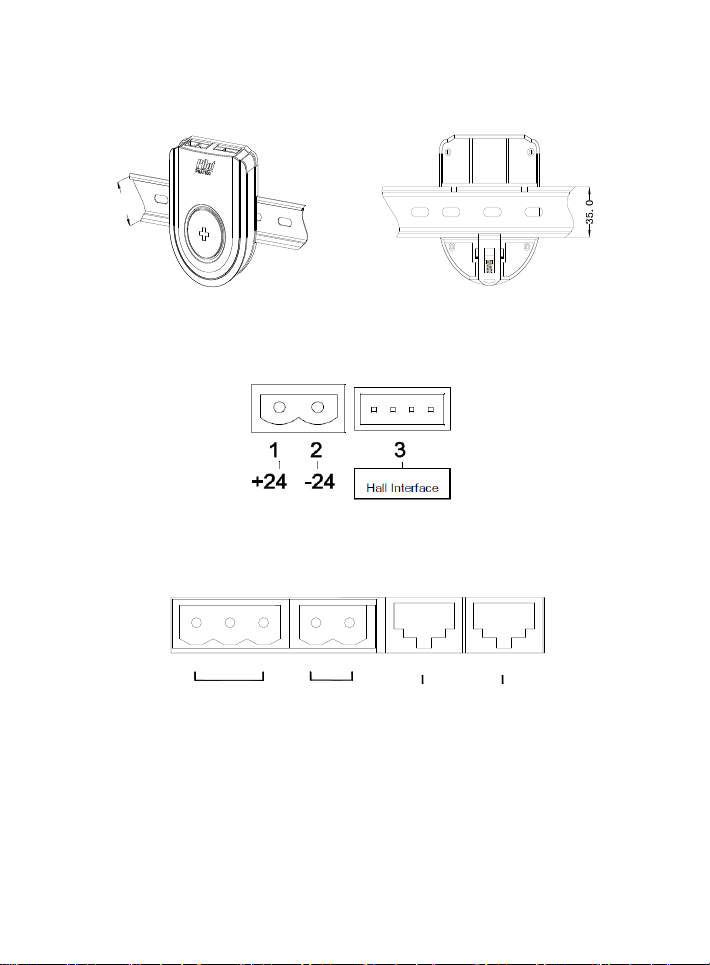

Chapter 1 Product Overview

PBAT600 battery string sensor is specially designed as highly integrated smart sensor

module for VRLA batteries, can quickly and accurately measure the VRLA’s voltage,

charge and discharge current and other parameters. String sensor uses specified

isolated communication bus, equipped with PBAT61 battery cell sensor, to realize the

real-time monitoring of the entire string of batteries. Real-time control of the actual

operation of the battery string and health status, then promptly found problems during

use battery. Real-time know the actual operation of the battery pack and health status,

and discover the battery string existing problems during using, and realize automatic

maintenance functions. It helps the battery string to keep voltage balance under float

status, so that each unit of the battery to maintain the best active status, improve the

battery life, timely find out the problem battery and maintenance, reduces labor cost

and other maintenance costs, improve the safety of battery use to reduce the accident

rate.

The PBAT600 string sensor can fulfill following functions:

Real-time monitoring of the entire string of battery voltage, charge and

discharge current, Battery string of SOC, SOH.

PBAT600 and PBAT61 series with the use of a dedicated isolation bus

real-time monitoring of each battery voltage, internal resistance,

temperature, SOC, SOH.

Auto-sensing for S/N, without excessive manual intervention and

configuration, reducing engineering effort.

About the PBAT61 program upgrade, you can use the local 600 to upgrade.

Advanced measurement algorithm, no need for high current discharge, to