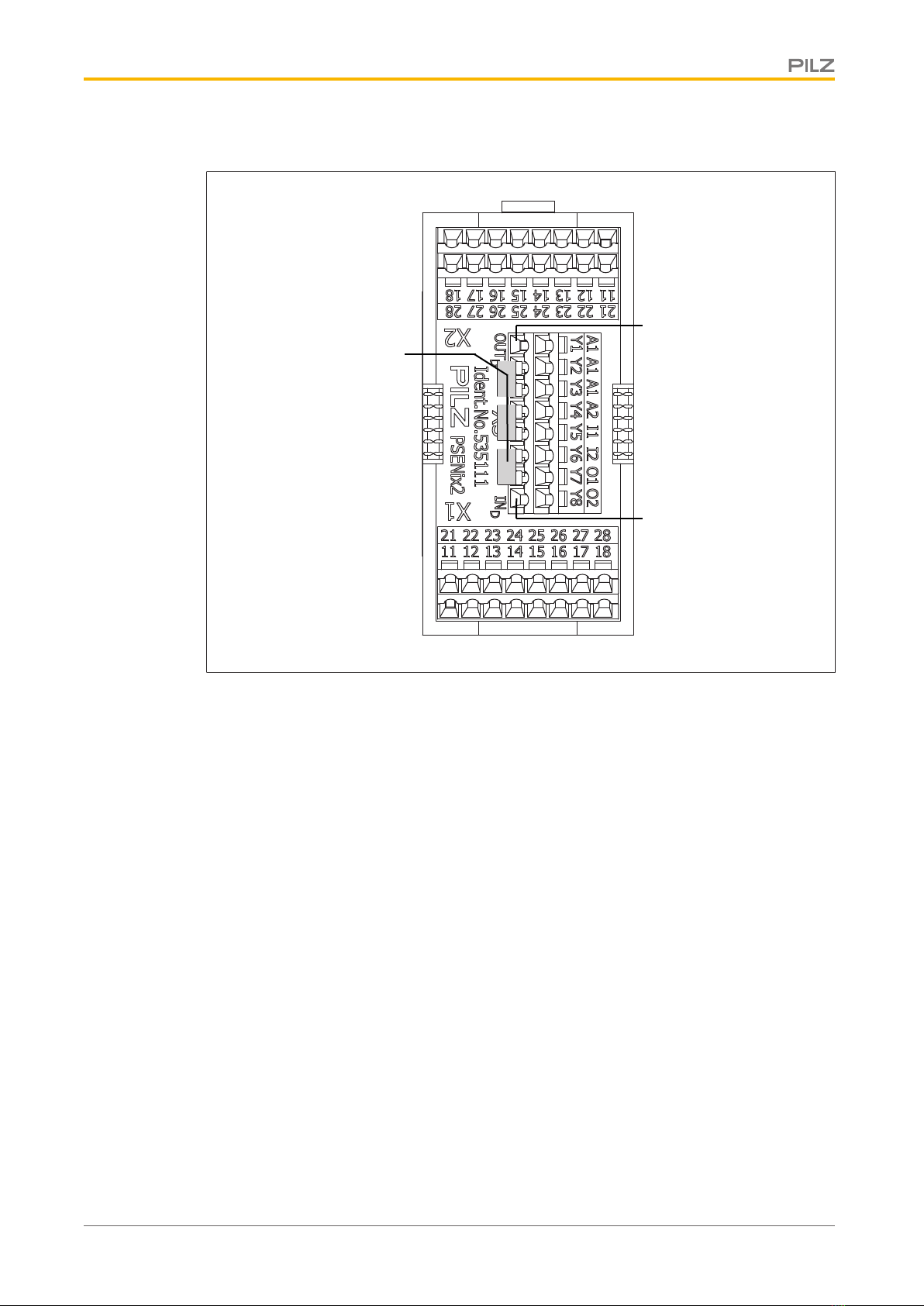

PSEN ix2 F4 code

Operating Manual PSEN ix2 F4 code

1003823-EN-02 7

Safety

Intended use

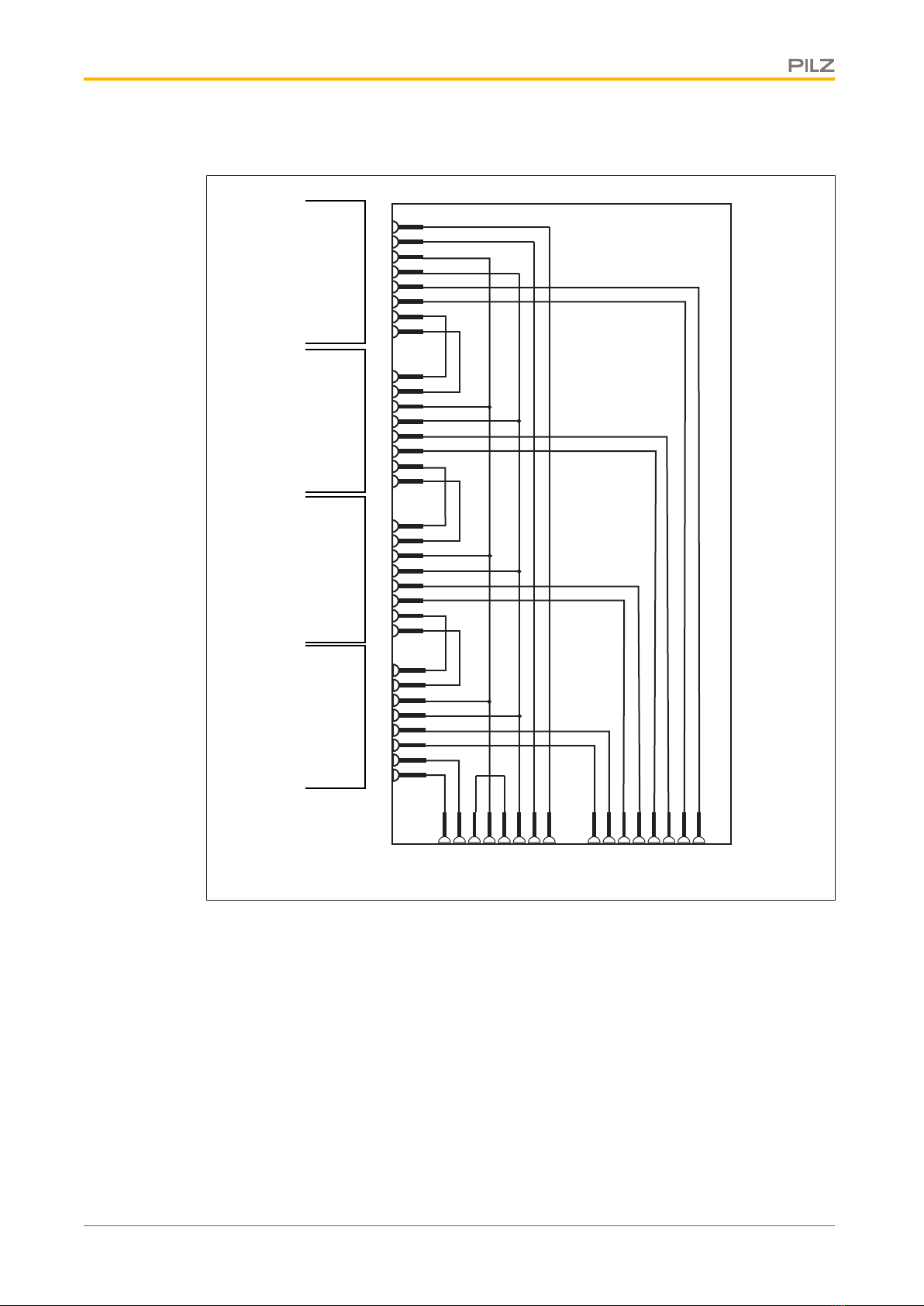

The PSEN ix2 F4 code is an interface for connecting series-connectable PSENcode,

PSENslock, PSENini sensors to an evaluation device.

}Connection to Safety Device Diagnostics (SDD) and forwarding of diagnostic informa-

tion from the connected sensors to a fieldbus module. Further information is provided in

the document entitled "System Description Safety Device Diagnostics".

}Series connection of PSEN sensors and connection to an evaluation device

A max. of 4 PSEN sensors can be connected to a PSEN ix2 F4 code. All sensors must be

8-pin, with 2 safety inputs each.

The following is deemed improper use in particular:

}Any component, technical or electrical modification to the product

}Use of the product outside the areas described in this manual

}Use of the product outside the technical details (see Technical details [ 16]).

NOTICE

EMC-compliant electrical installation

The product is designed for use in an industrial environment. The product

may cause interference if installed in other environments. If installed in other

environments, measures should be taken to comply with the applicable

standards and directives for the respective installation site with regard to in-

terference.

Safety regulations

Additional documents that apply

Please read and take note of the following documents:

}Operating manual for the relevant Pilz safety device

}Operating manual for the fieldbus module, for example SDD ES ETH or SDD ES

PROFIBUS

}System description "Safety Device Diagnostics"

You will need to be conversant with the information in these documents in order to fully un-

derstand this manual.

Use of qualified personnel

The products may only be assembled, installed, programmed, commissioned, operated,

maintained and decommissioned by competent persons.

A competent person is someone who, because of their training, experience and current pro-

fessional activity, has the specialist knowledge required to test, assess and operate the

work equipment, devices, systems, plant and machinery in accordance with the general

standards and guidelines for safety technology.