3.

CIRCUIT

DESCRIPTIONS

3.1 PLAYBACK

CIRCUIT

The signal from the playback head is amplified

by the Q102/Q103 2-stagedirect-coupled ampli-

fier. In the NORM position, the playback equali-

zation (120ps) compensation is achieved by the

NF circuit between the Q103 collector and Q102

emitter. In the METAL and CrOz positions,Q104

is turned on, and the equalization characteristics

switched from 120ps to 70ps to compensatethe

frequency response. The level of the EQ AMP

output is set by a variable resistor, and further

amplified by the Q401 flat amplifier before being

parised

through the MPX filter and applied to pin

2 of the Dolby IC.

This Dolby circuit consistsof IC401 (HA11226),

and the Dolby ON/OFF switch is linked to the

MPX filter ON/OFF switch. When the Dolby

switch is OFF, the 19kHz filter is bypassed.

The Dolby circuit output appears at pin 8 of

IC401, and is passed to LINE OUTPUT via a

switchingIC (IC402).

3.2 RECORDINGCIRCUIT

The input signal from the microphone jack is

amplified by the microphone amplifier IC101, and

passed via the MIC/LINE selector switch to the

INPUT volume control where the input level is

adjusted. This adjusted signal is passedvia IC103

to flat amplifierQ40l. D313 andD314 in the stage

before IC103 form a protector circuit designed

to protect IC103 from large input signals. The

signal amplified by the flat amplifier is pa.ssed

via

the MPX filter to pin 2 of the Dolby IC, the output

appearing at pin 8. The level of this output is

adjusted by variable resistor. Then after equaliza-

tion in the REC AMP (Q106) in accordance

to

the type of tape being used, the signal is passed

to the recordinghead. +g

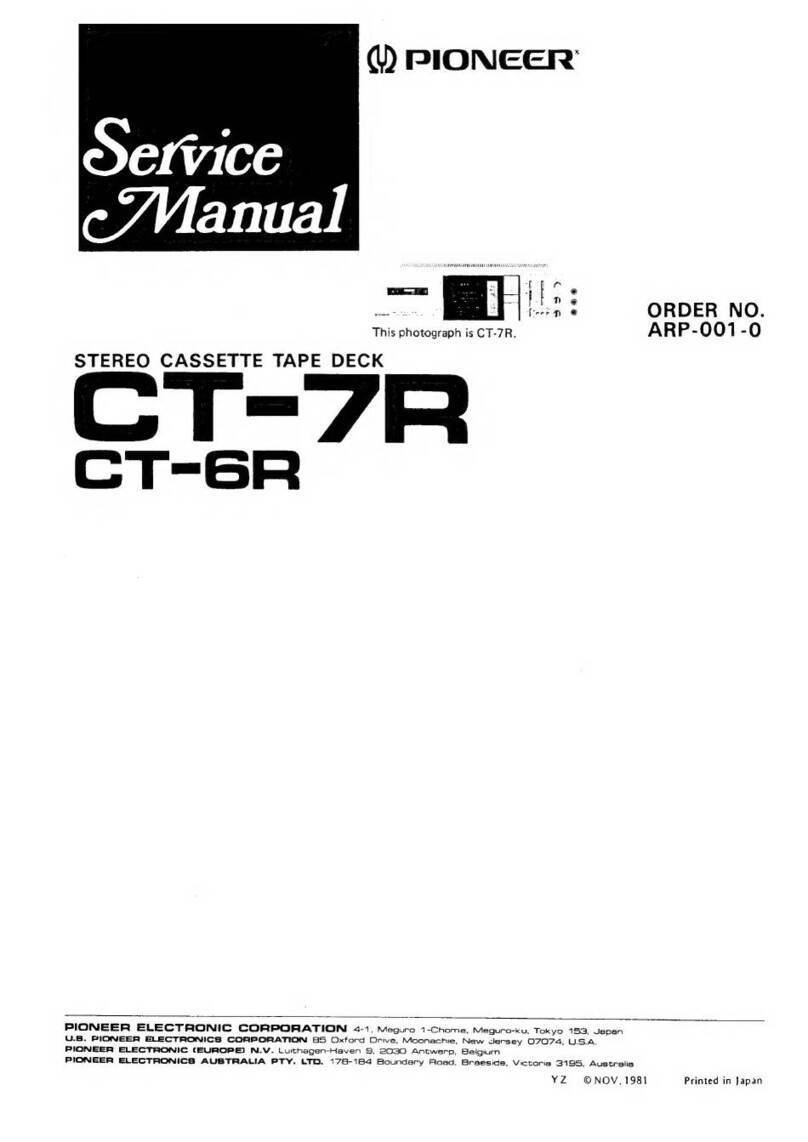

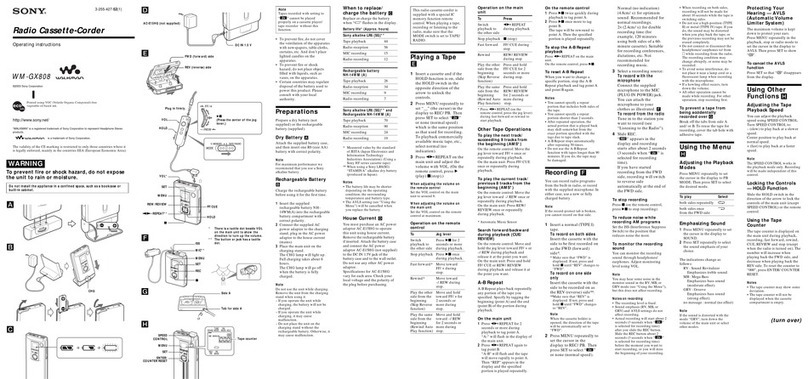

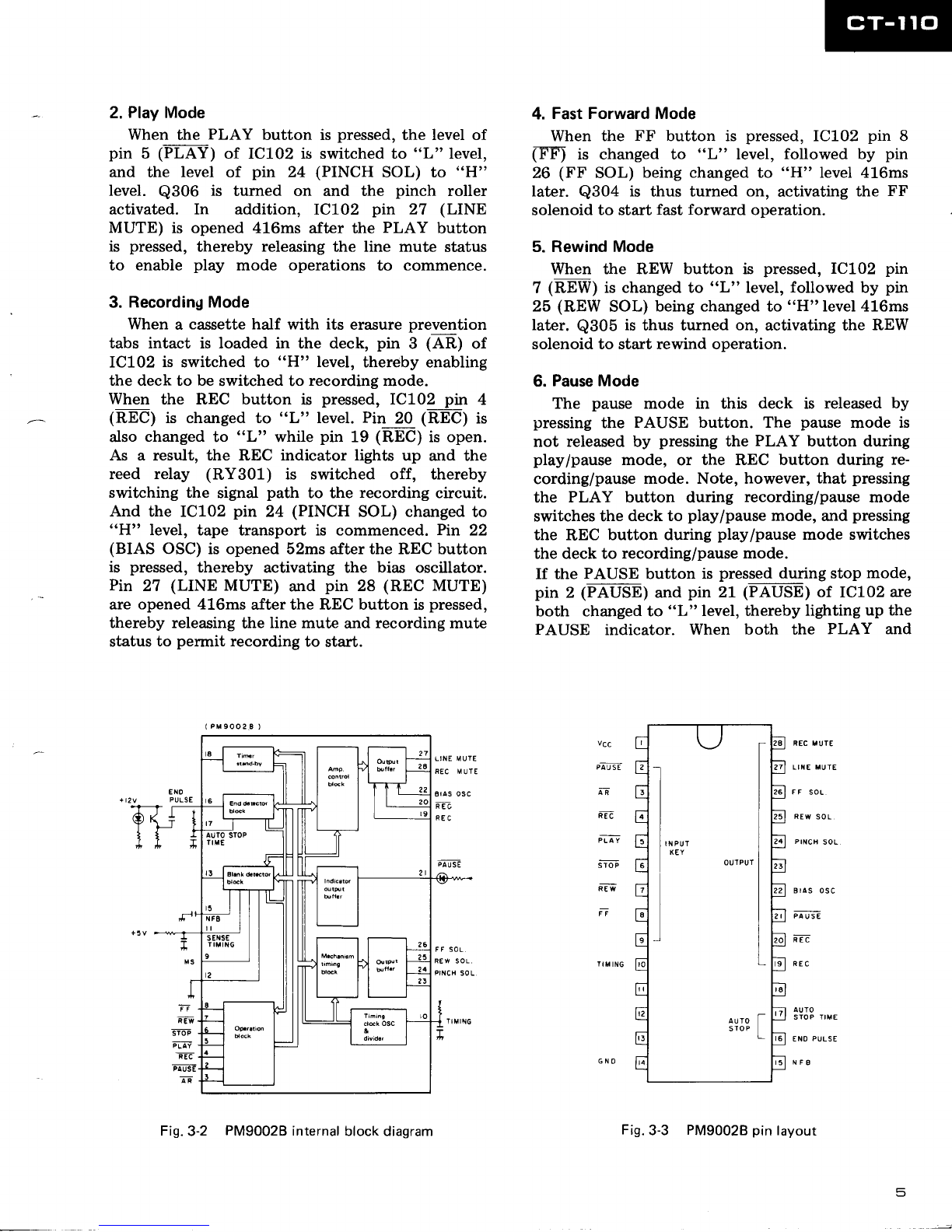

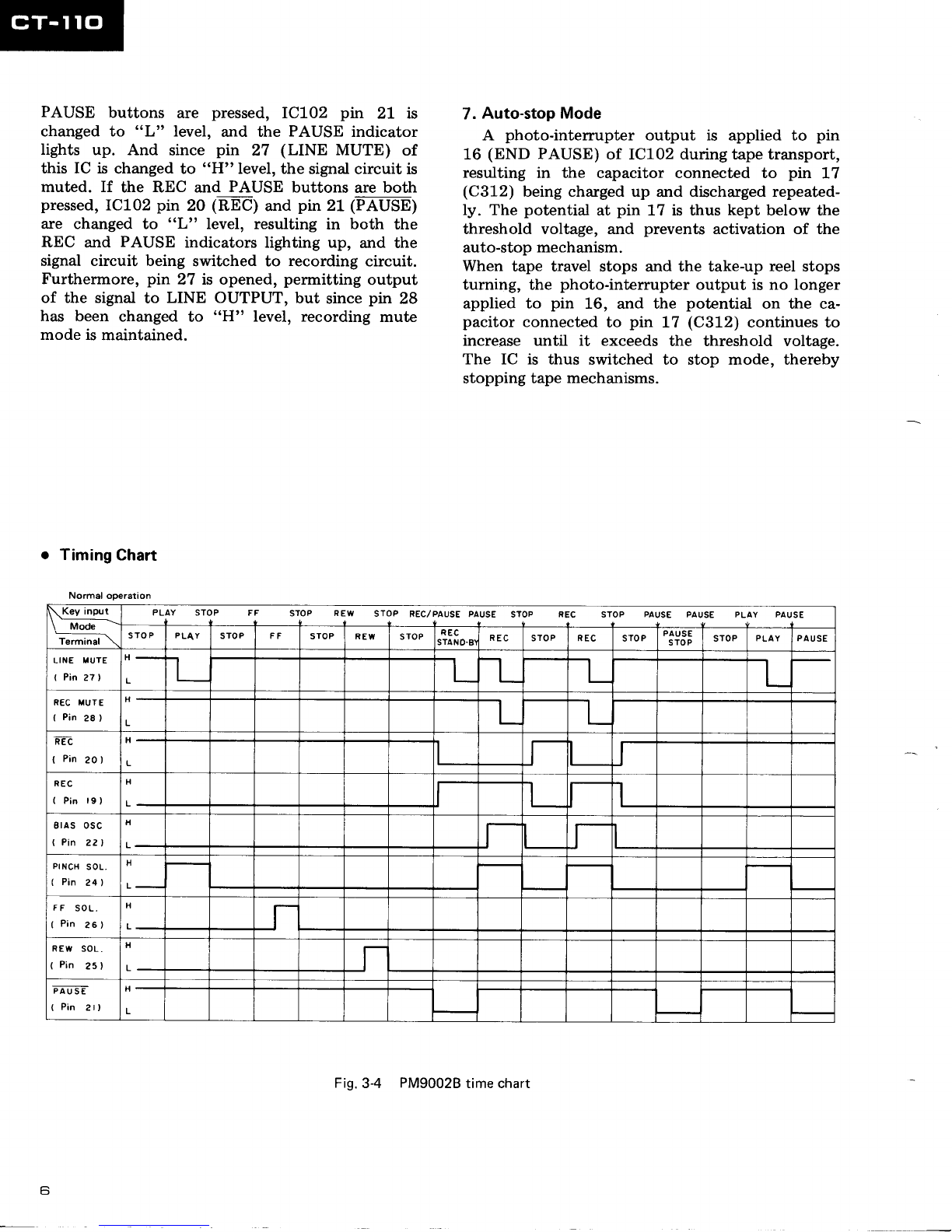

3.3 CONTROLCIRCUIT

The control circuit in this deck utilizes a one-

chip IC (PM90028) which enablesfeather-touch

operations. In addition to mechanism control,

this IC also includes auto-stop function. And due

to the digital counter frequency divider system

employed in timing settings for the mechanism

control, all operational timing discrepancies have

been eliminated. The PM9002B pin layout is

shown in Fig. 3-3, the functional block diagram

in

Fig. 3-2, and the output pin time charts during

different modes in Figs. 3-4 and 3-5. For inter-

relations between circuits, see the block diagram

onpage

10,11 andin Fig.3-1.

4

Operations

duringEachMode

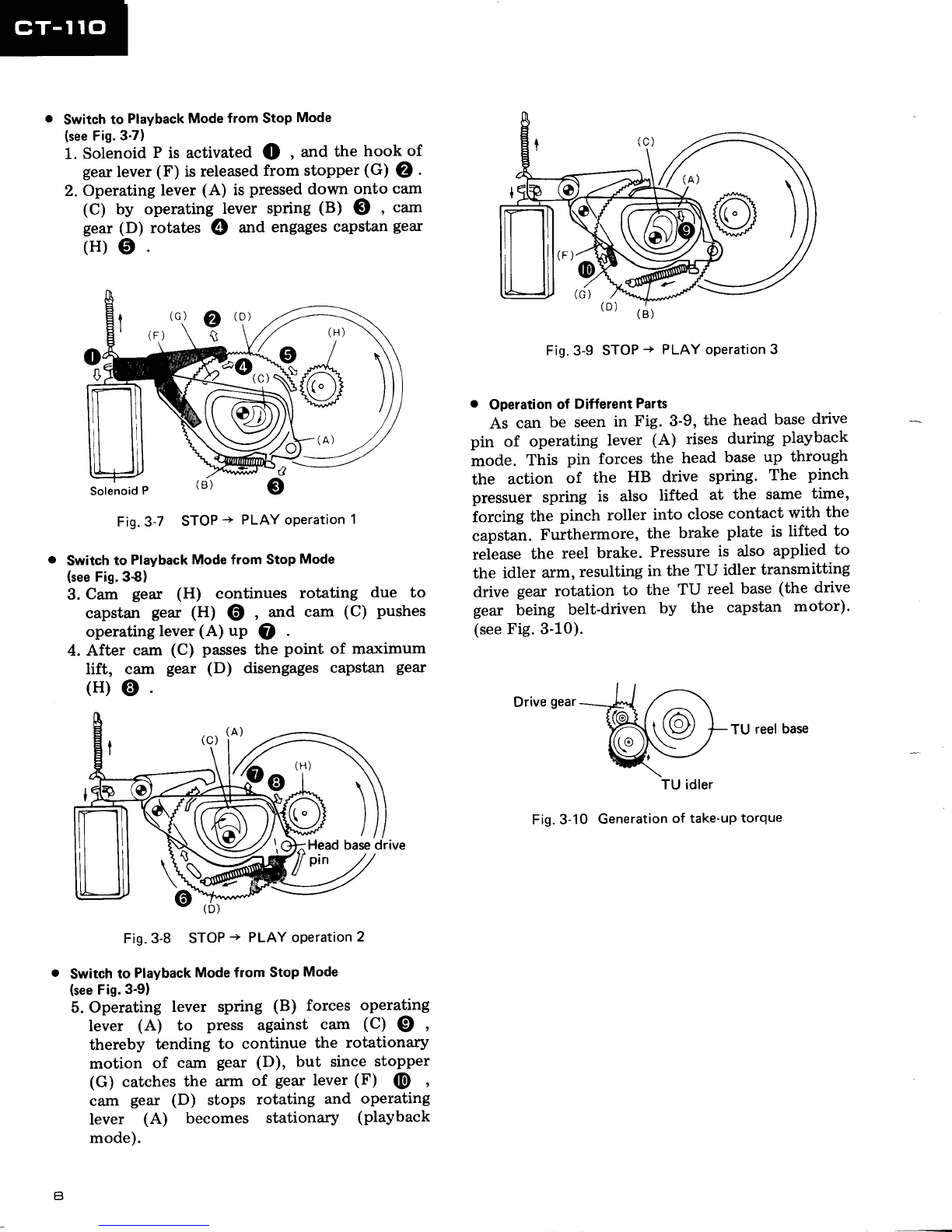

The mechanical operations effected by the

following circuit changes

are described in the next

chapter (seepage

7).

1.When

the POWER

Switch is

SwitchedON

When the POWER switch is switchedon, *5V is

applied to pin 1 (Vcc) of IC102. During the initial

period when pin 1 voltage is being increased from

0V to 5V (approximately from 0.6V to 2.4V) the

IC's intemal reset circuit is activated, putting the

IC into stop status which is maintained for about

four seconds

after the power switchisswitchedON.

During this time, no change can be effected by

pressing

any of the other operation control buttons.

REC/PB

head

LINE

OUTPUI

rcroz

PM9OO2

B

pquse

an

REC REC

pr-a

y REc

STOP PAUSE

REW BIAS

osc

oFa

MUTE

SIGNAL

MS

LINE

PINCH MUTE

REw "iI&,

Er ENO

OETECT

TIME

Fig.3-1 Controlsystem

blockdiagram