2011 NEW PRODUCTS

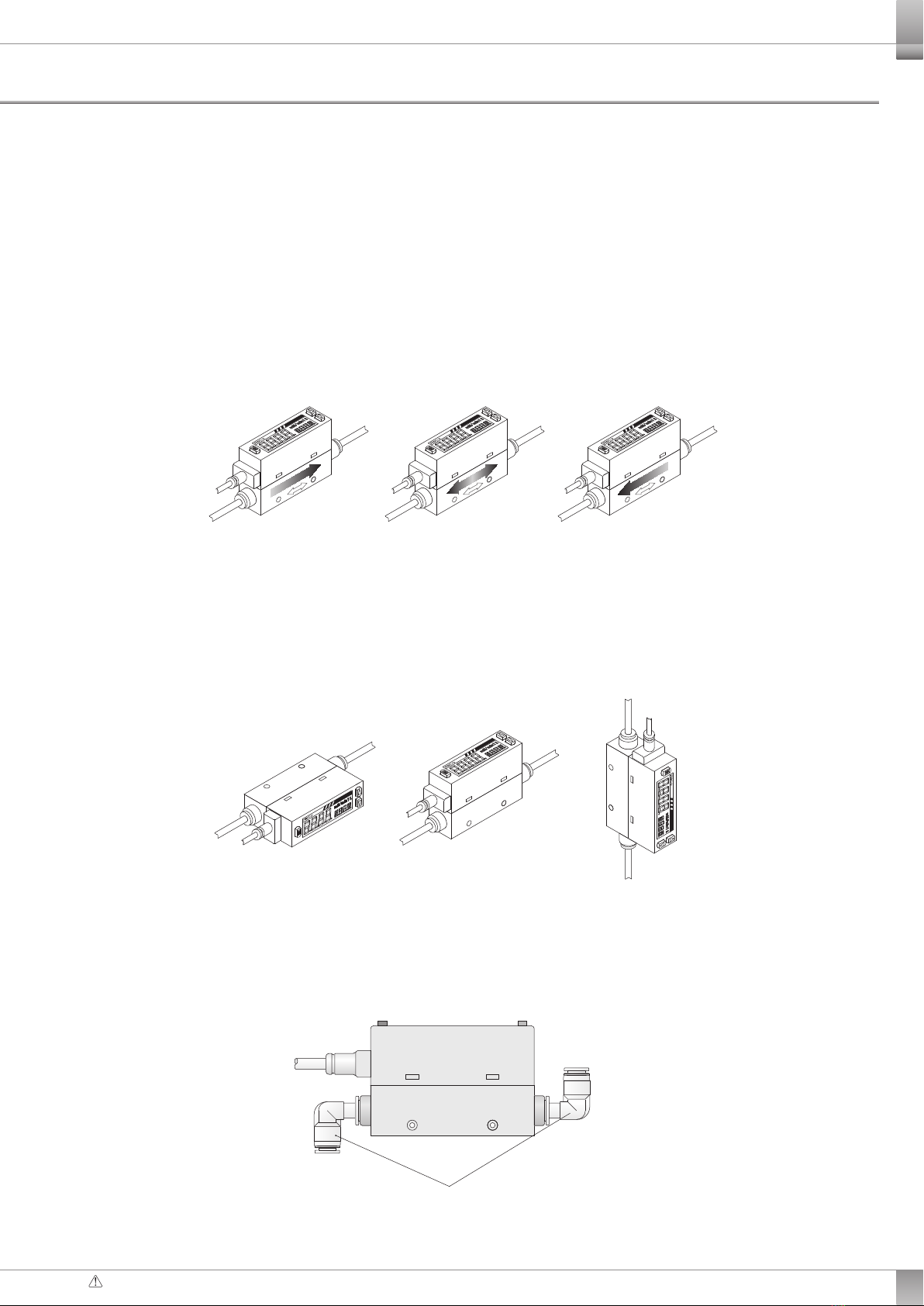

Please be sure to read before handling the product. Please refer to "safety instructions", "common safety instructions for products listed in this manual", "common safety instructions for ow controller" from page 24 through 35.

6

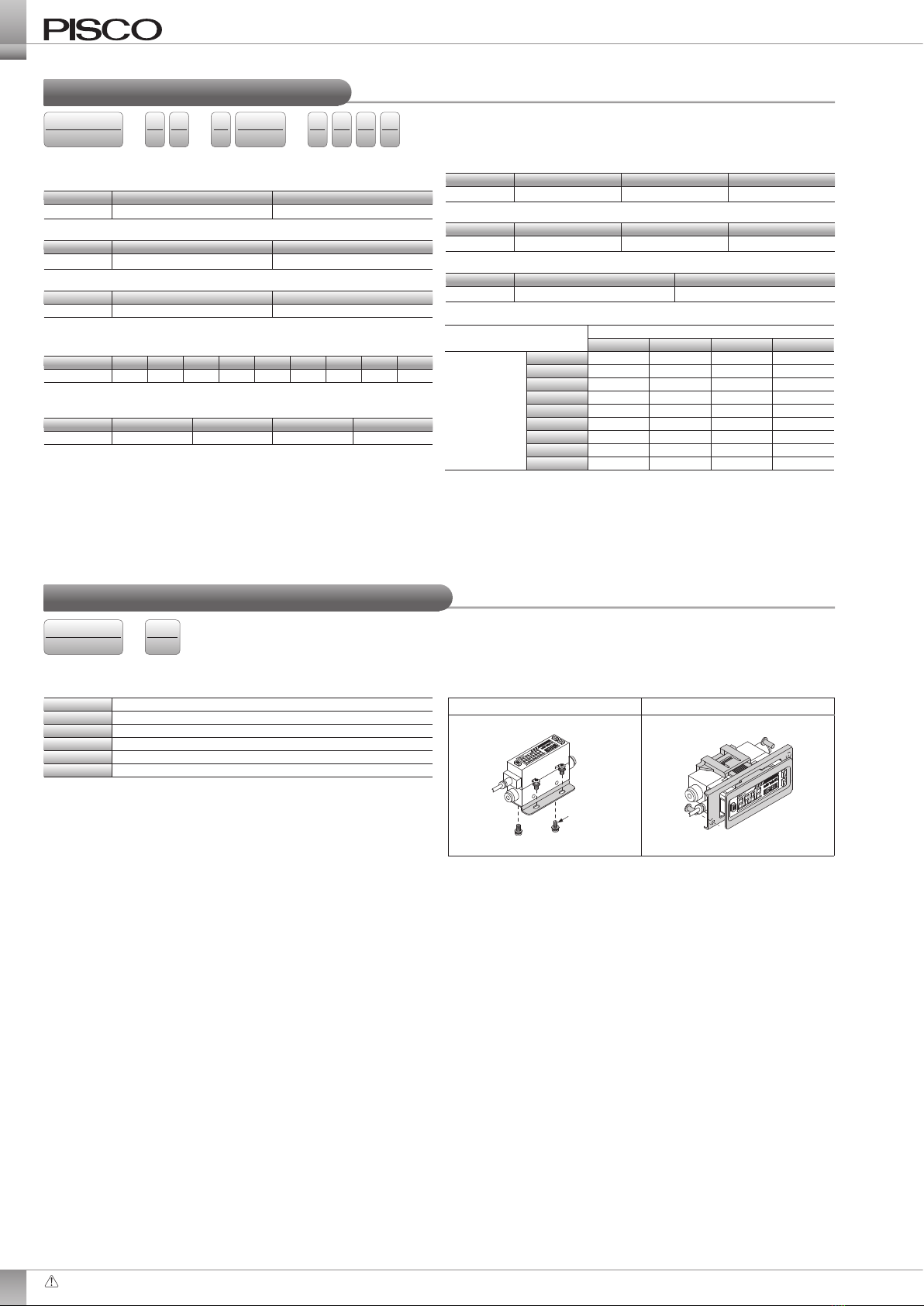

Specication

Item Full-scale ow 005 010 020 050 100 200 500 101 201

Flowrate

range

(*1)

005 500ml/min ●

010 1l/min ●

020 2l/min ●

050 5l/min ●

100 10l/min ●

200 20l/min ●

500 50l/min ●

101 100l/min ●

201 200l/min ●

Port size

4

ø4mm Quick-fitting

●●●●●●

6

ø6mm Quick-fitting

●●●●●●●

8

ø8mm Quick-fitting

●●●

10

ø10mm Quick-fitting

● ●

Built-in needle valve

N (*9)●●●●●●●●●

Flowrate display

(*1) (*2)

Display method 4digits +4digits, 2color LCD

Display

range

F0~500

ml/min

0~1000

ml/min

0~2.00

l/min

0~5.00

l/min

0~10.00

l/min

0~20.0

l/min

0~50.0

l/min

0~100.0

l/min

0~200

l/min

R

-500~500

ml/min

-1000~1000

ml/min

-2.00~2.00

l/min

-5.00~5.00

l/min

-10.00~10.00

l/min

-20.0~20.0

l/min

-50.0~50.0

l/min

-100.0~100.0

l/min

-200~200

l/min

Minimum unit setting

1ml/min 0.01l/min 0.1l/min 1l/min

Accumulation

(*3)

Maxflowrate 9999999ml99999.99l999999.9l

9999999l

Mini. unit setting 1ml0.01l0.1l1l

Accumulated pulse output rate

5ml10ml0.02l0.05l0.1l0.2l0.5l1l2l

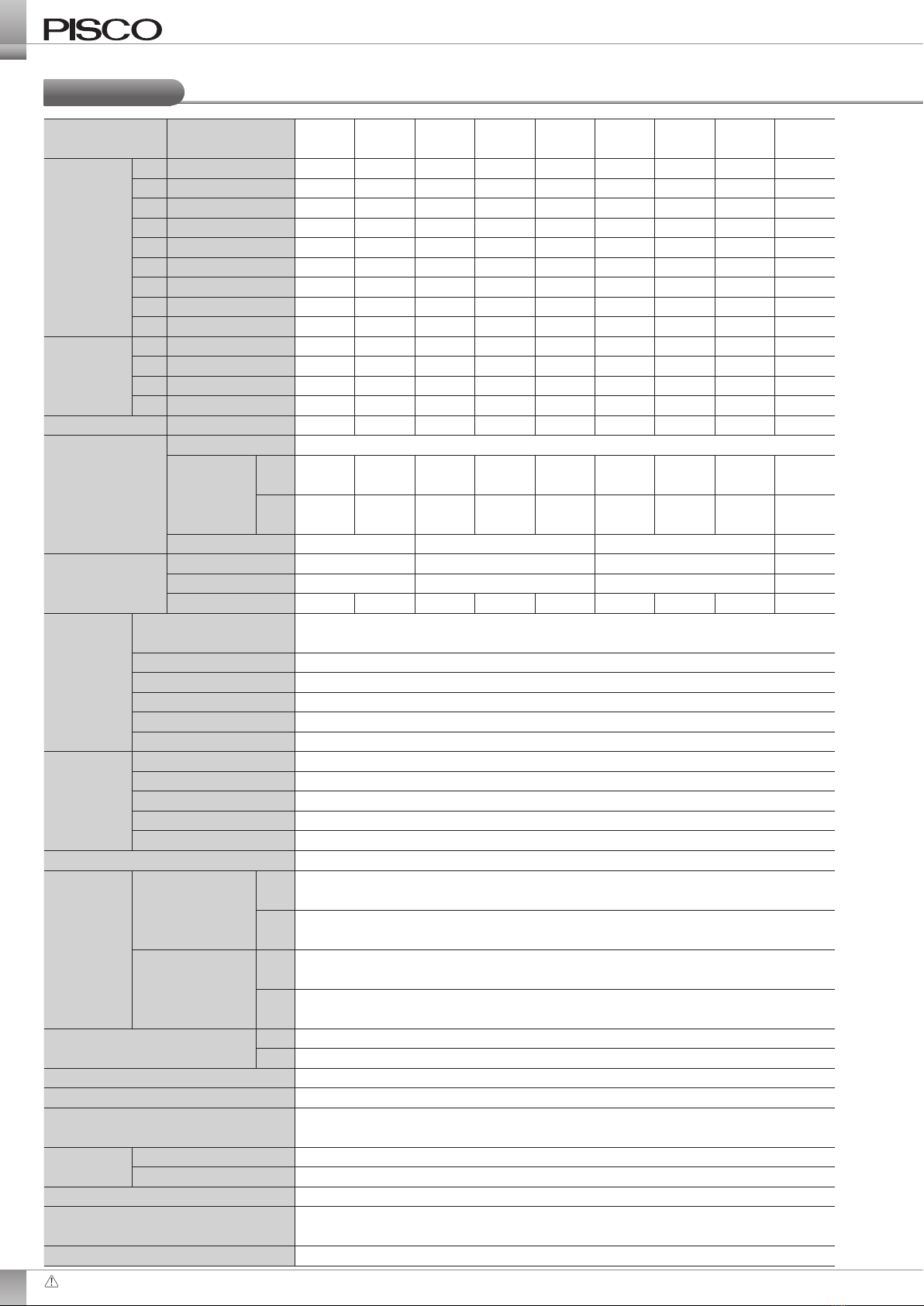

Working

condition

Fluid medium (*4) Clean air (JIS B8392-1.1.1to 5.6.2), Compressed air (JIS B8392-1.1.1to 1.6.2),

and nitrogen gas

Maxworking pressure 0.7MPa

Min working pressure -0.09MPa

Withstand pressure 1MPa

Ambient Temp. & humidity

0to 50ºC, max. 90%RH

Working fluid temp. 0to 50ºC (no dewcondensation)

Accuracy

Assured accuracy range

3~ 100%F.S.

Linearity (display/analog output)

Max±3%F.S. (Air vent for 2ndary side、25ºC)

Pressure characteristics

Max±5%F.S. (-0.09 to 0.7MPa, where air vent for 2ndary side is reference)

Temp. characteristics Max±0.2%F.S./ºC (15 to 35ºC, where 25ºC is reference)

Repeatability Max.±1%F.S.

Response time (*5) Max.50ms

Output

Switch output

N 2 points output (NPNopen collector output: max. 50mA, voltage drop: max. 2.4V)

P2points output (PNP open collector output: max. 50mA, voltage drop: max. 2.4V)

Analog output

V1voltage output 1to 5V (connected load impedance: min. 50kΩ)

A Current output 4to 20mA (connected impedance: 0to 300Ω)

Power supply voltage (*6)

V DC12 ~ 24V (10.8 ~ 26.4V)

A DC24V (21.6 ~ 26.4V)

Current consumption (*7)Max.50mA

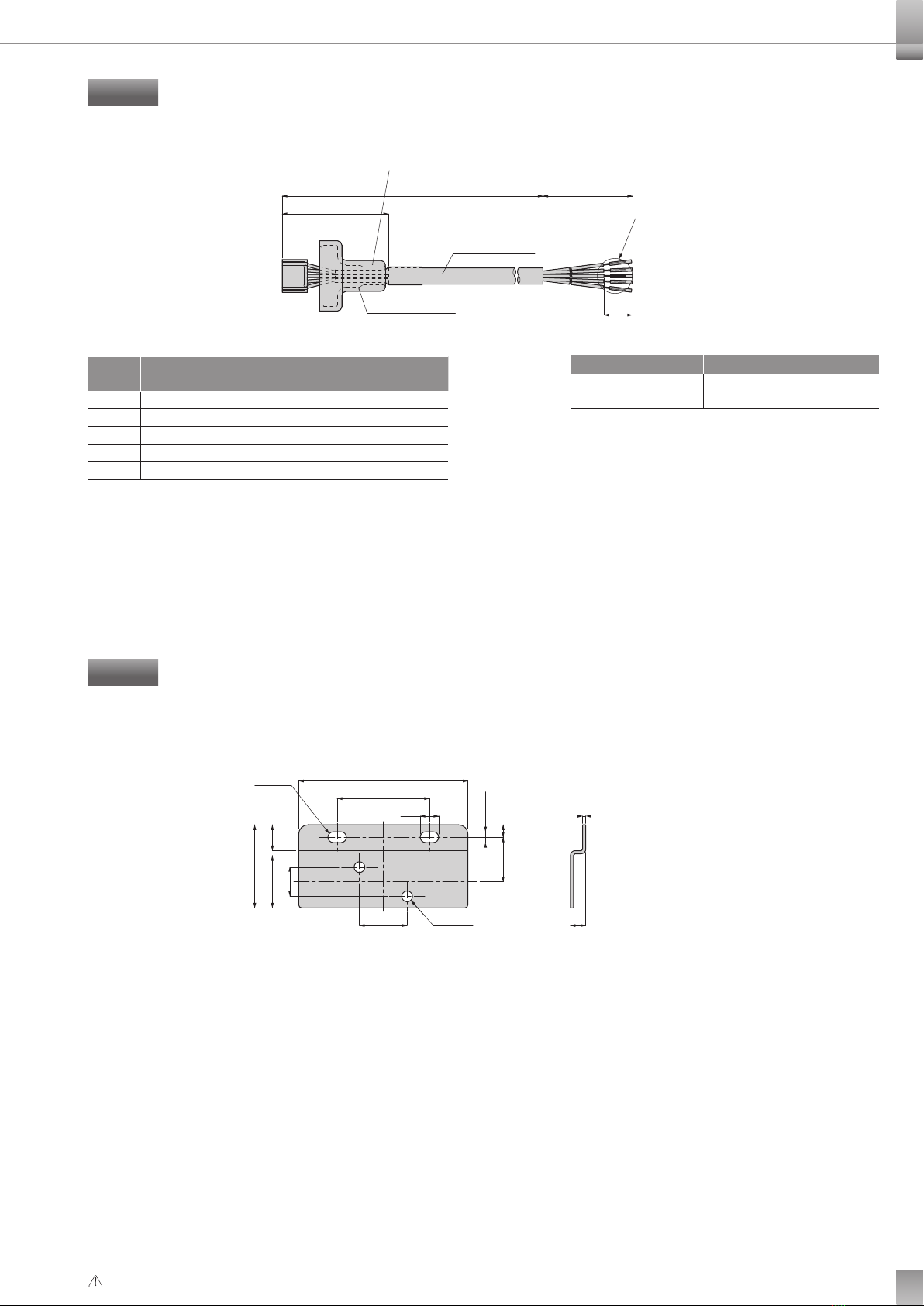

Lead wire ø3.7 AWG26 equiv. x5core cable (connector joint), Insulator O.D. ø1.0mm

Functions Flowrate display, flowrate -peak hold, switch output, analog output, and other

Installation Installing orientation Horizontal or vertical

Straight pipe introduction

Not required

Protective structure IEC standard: IP40

Protective circuit (*8)

Power supply and switch output reverse connection protections, and switch output

load short-circuit protection

EMC directive Conformity