Safety instruction manual

Warnings

1.When the fluid medium is chemicals, solvents or mixed gases, check the chemical resistance before using the products. Damage or

leakage may occur to the valve upon the usage.

2.Do not use the valve in applications that cause shaking or shocking. Damage or leakage may occur to the valve upon usage.

3.Do not use the products in environments that have vibration or shocking. Damage or leakage may occur to the valve upon usage.

4.Use soapy water or any other method to check for leakage before use.

5.After installation, carry out maintenance and leakage inspections periodically, considering the environment on frequency,

temperature, fluid flow rate, pressure, fluid medium, etc. Danger to to human life can occur from oxygen deficiency etc.

6.Do not retighten the product while pressurized. Valve deformation or breakage may occur and lead to fluid spouting. Make sure to set

pressure to “0” and lower the temperature to normal before retightening.

7.Do not use the valve outside of its stated specification. Otherwise accidents like a fluid leakage or piping coming-off may occur.

8.

Fluid and pressure may remain inside the valve when turning it to on/off while pressure is supplied. The residual fluid pressure may

increase due to rise in temperature. If the pressure exceeds maximum operating pressure, valve breakage or fluid leakage may occur.

9.The ball seat may deform or wear out, and cause leakage in cases where fluid medium has high temperature and high flow rate or is a

two-phase fluid mixed with small particles.

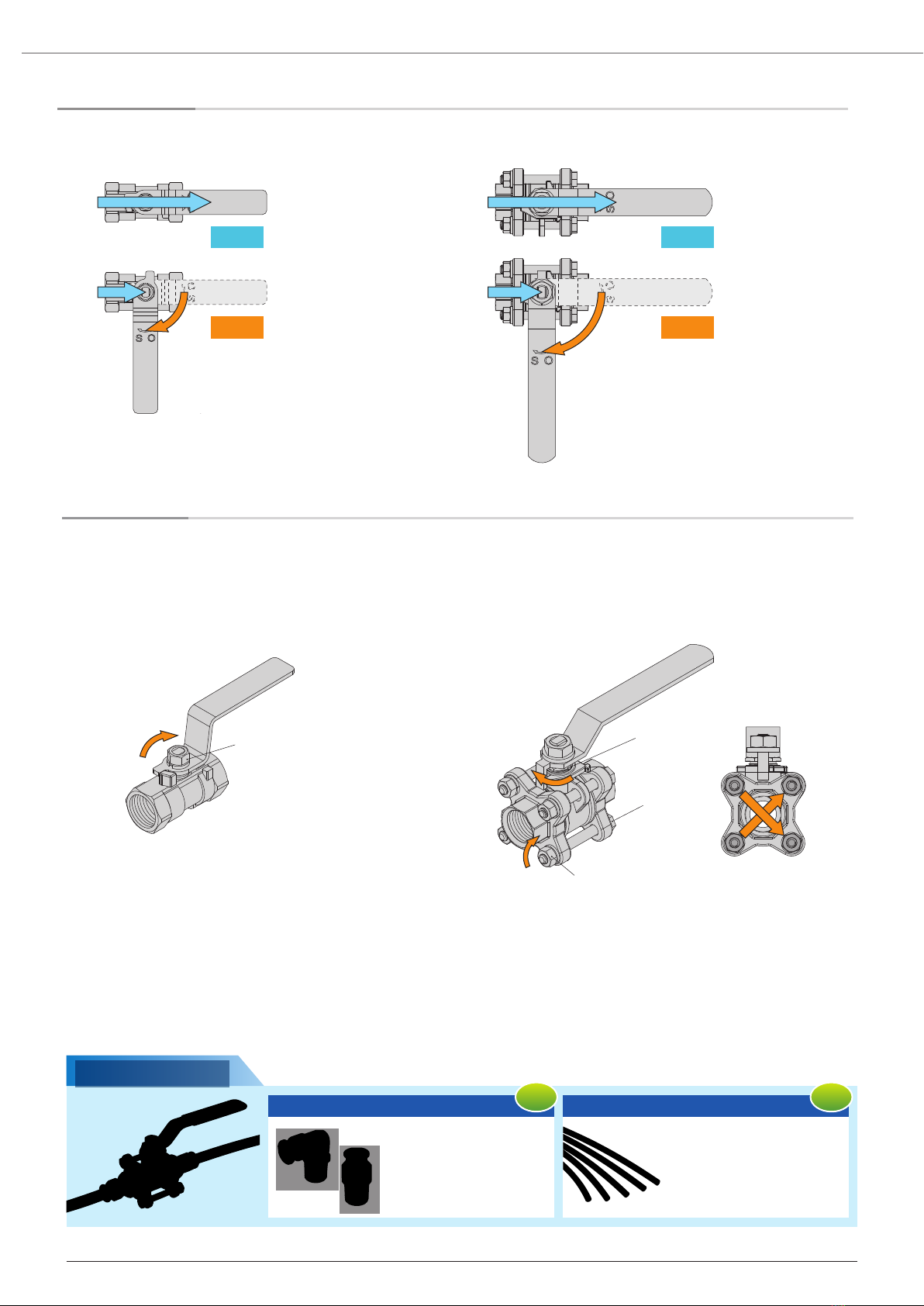

10.When opening or closing the valve, turn the handle to the fully open or closed position. Leaving the handle in the mid-way position may

cause scratching on the ball seat, fluid leakage and decrease lifespan for the valve.

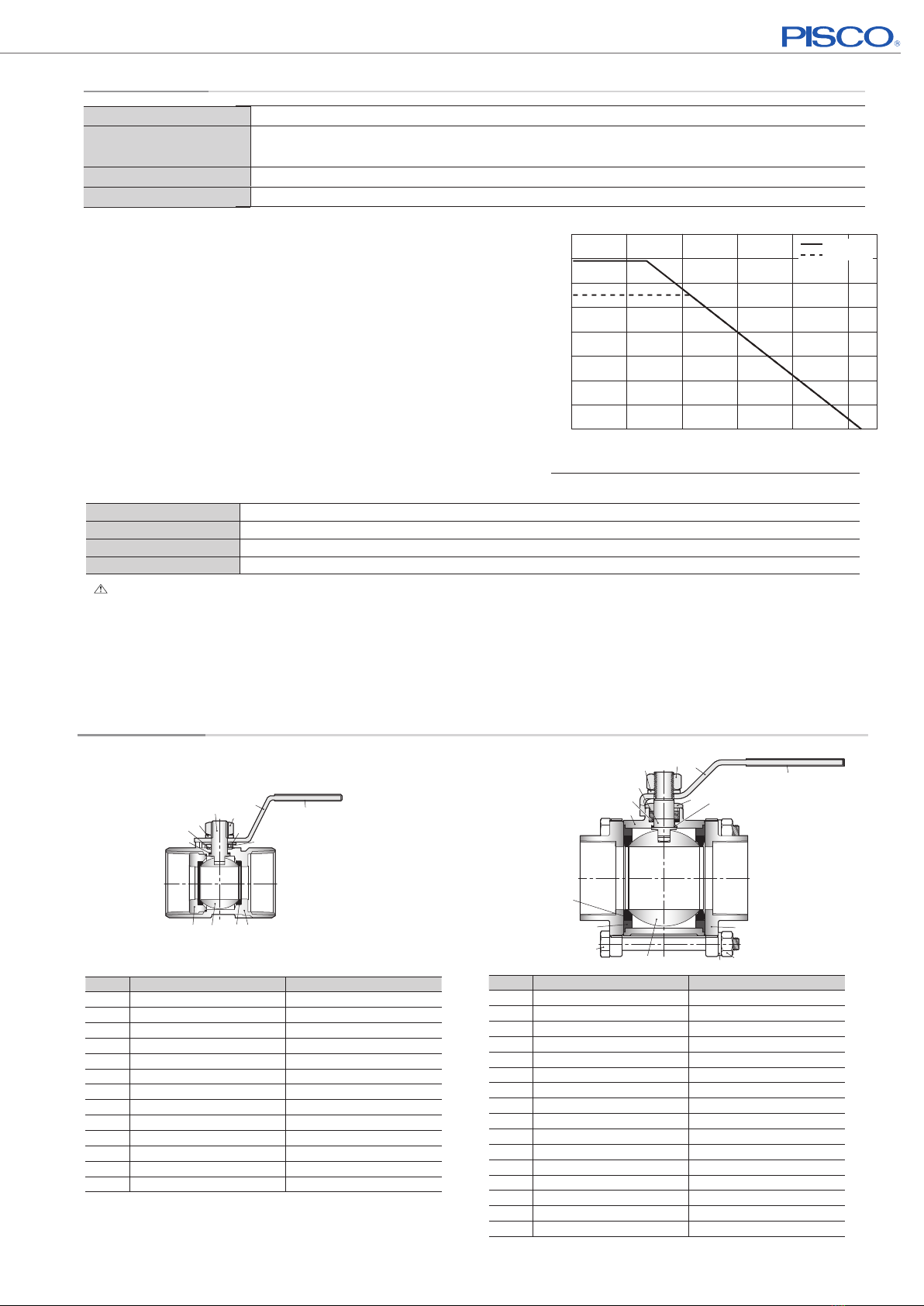

11.Used alone, the maximum operating pressure of the valve is its own stated maximum operating pressure. However, when using the

valve with a push-in fitting, the maximum operating pressure should be that of the push-in fitting.

Cautions

1.Do not disassemble or modify valve except for replacing handles. Doing so will damage the valve function.

2.Do not touch valve while using in a high temperature environment.

3.Make sure to understand the valve's components' material properties, considering the fluid medium and usage environment before

use. Most parts are made of SUS316 equivalent, but some parts where the fluid medium does not come into contact are made from

SUS304 equivalent.

4.Consider the load-bearing of the piping when installing the valve as it may cause deformation and leakage.

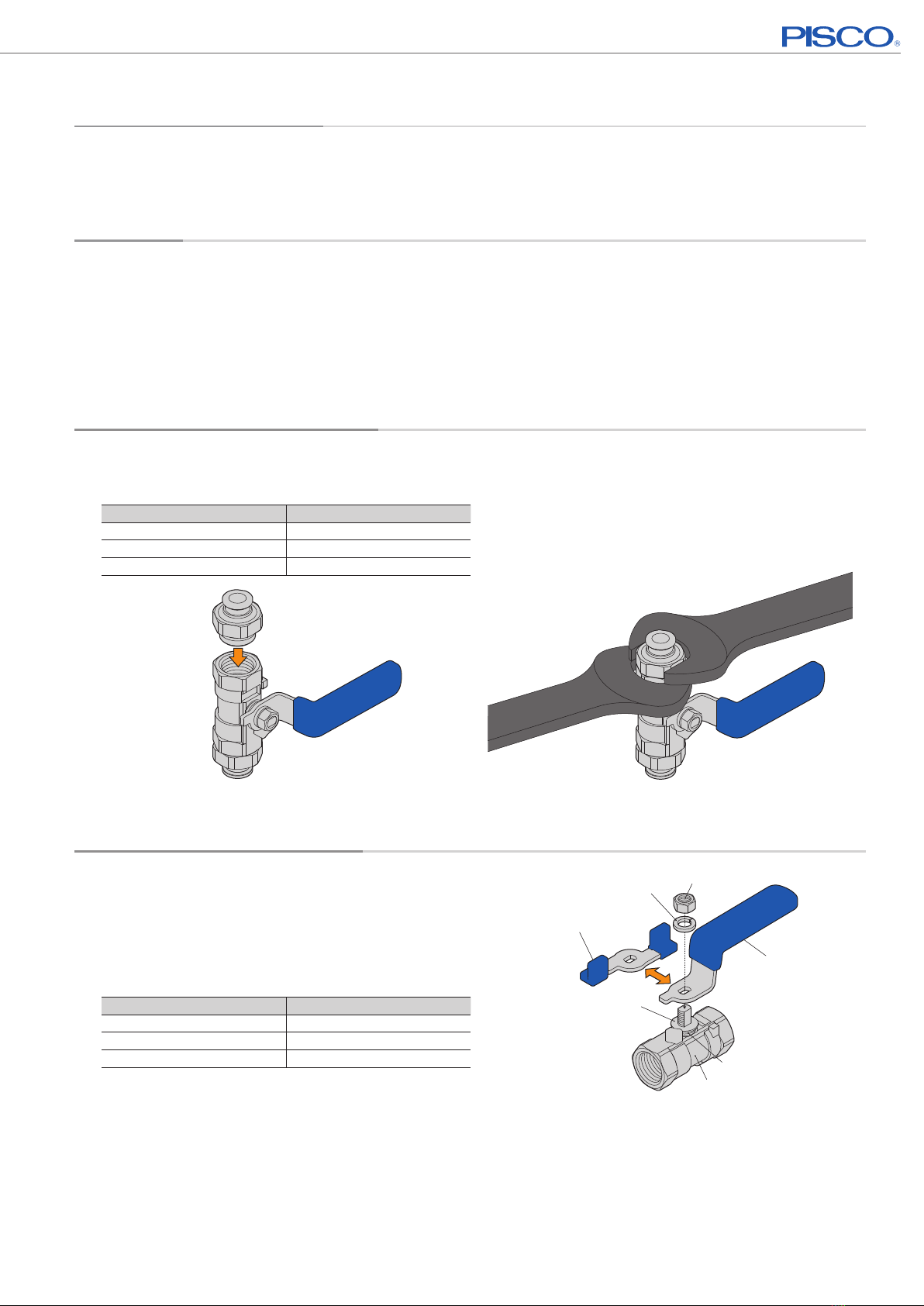

5.Do not tighten the thread too firmly. Excessive tightening can deform the valve body and ball seat. Follow the tightening torque guide for

tube fittings.

6.Make sure to position the wrench properly when tightening the valve. Otherwise, improper positioning may cause parts to loosen.

7.The valve is not completely oil-free as oil may remain from the assembly process.

8.The level of corrosion and dust emission from the valve varies by operating conditions. In case there is a possibility of negative effects

on machines or facilities due to these operating conditions, evaluate the suitability of the products in advance.

9.Depending on the service fluid and/or frequency of opening and closing the valve, the PTFE seal portion may wear out and generate

dust. . If your application does not allow any dust emission, please take countermeasures like installing filters located downstream of the

valve.

10.When used in vacuum systems, install a filter located in the upstream of the valve to prevent from clogging.

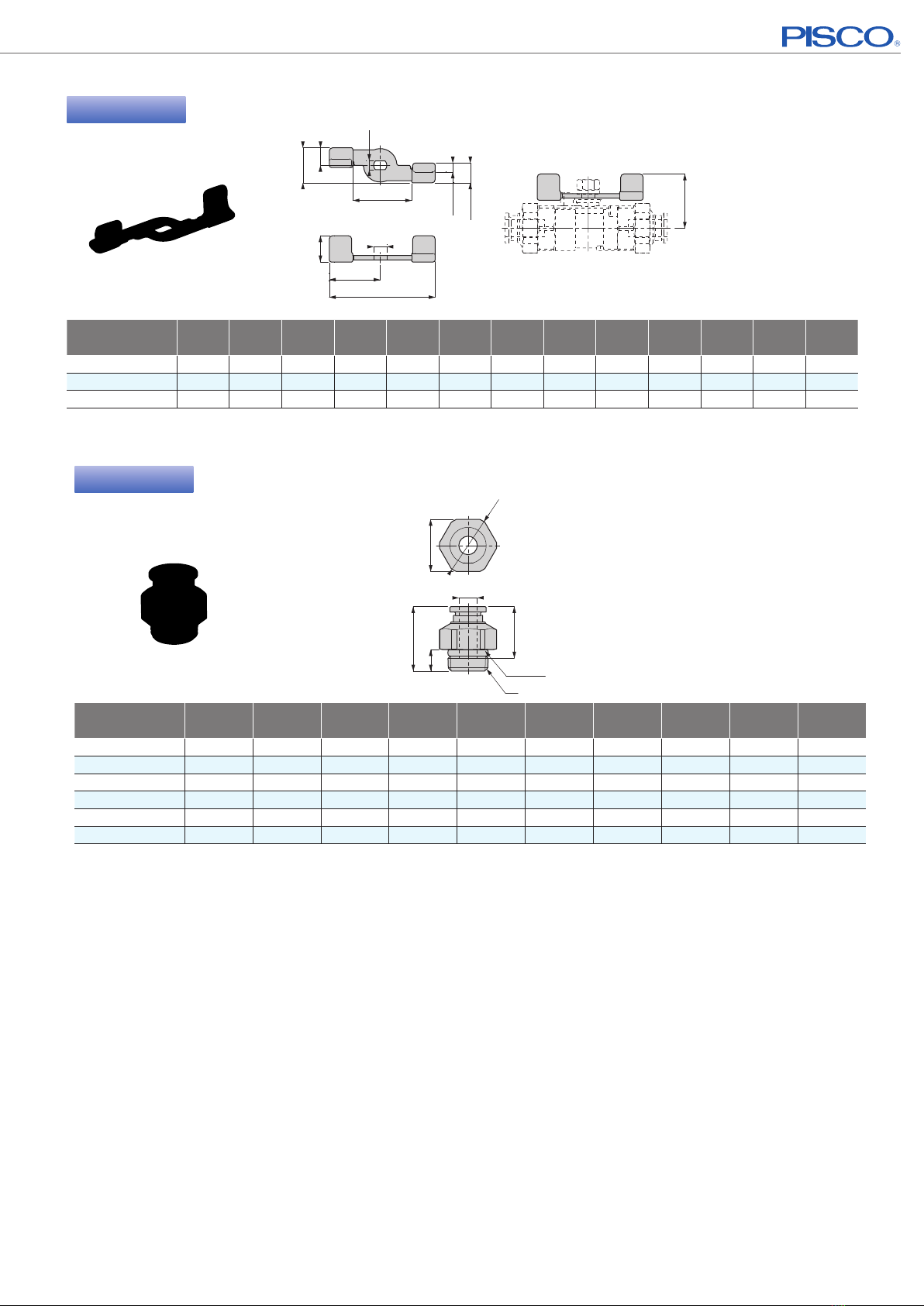

11.Specialized SUS316 fittings have been made specially to be used with the NSBVF10 ball valves. Using them for other uses may cause

leakage.

1. The level of corrosion and dust emission from the fittings varies by operating conditions. In case there is a possibility of negative

effects on machines or facilities due to these conditions, evaluate the suitability of the products in advance.

■SUS316 fitting safety instruction

Warnings

:KHQthe fluid medium isFKHPLFDOVVROYHQWVDQGPL[HGJDVHVFKHFNFKHPLFDOUHVLVWDQFHbefore using the products

Cautions

2.

3.

'HSHQGLQJRQthe FRQGLWLRQVthe fluid mediumPD\FDXVHGDPDJHWRWKHILWWLQJV such as WKHWXELQJFRPLQJRIIDQGIOXLGOHDNDJH

Do not use the product in applications where water and liquid do not meet the product specification. Otherwise, it may cause

damage to the fittings, such as the tubing coming off and fluid leakage.

Be sure to use an Insert Ring when the fluid being used is liquid. There is a possibility of the tubing coming off and fluid leakage

in the following situation.

・Using with fluid whose temperature changes drastically or under conditions where the temperature changes drastically.

・Using in high temperature environments.