Vacuum Pen

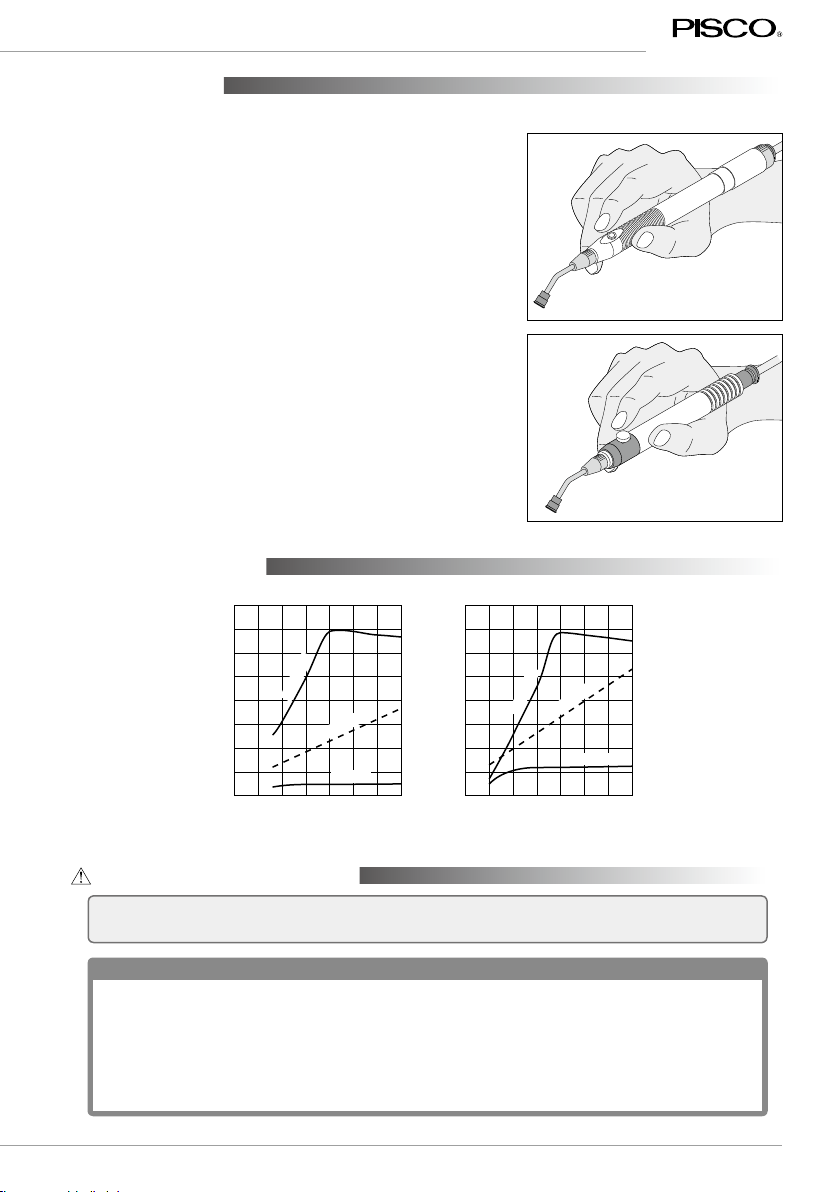

Common Safety Instructions for Vacuum Pads

Warning

Before selecting or using PISCO products, read following instructions. Read the

detailed instruction for individual series as the instructions below.

Caution

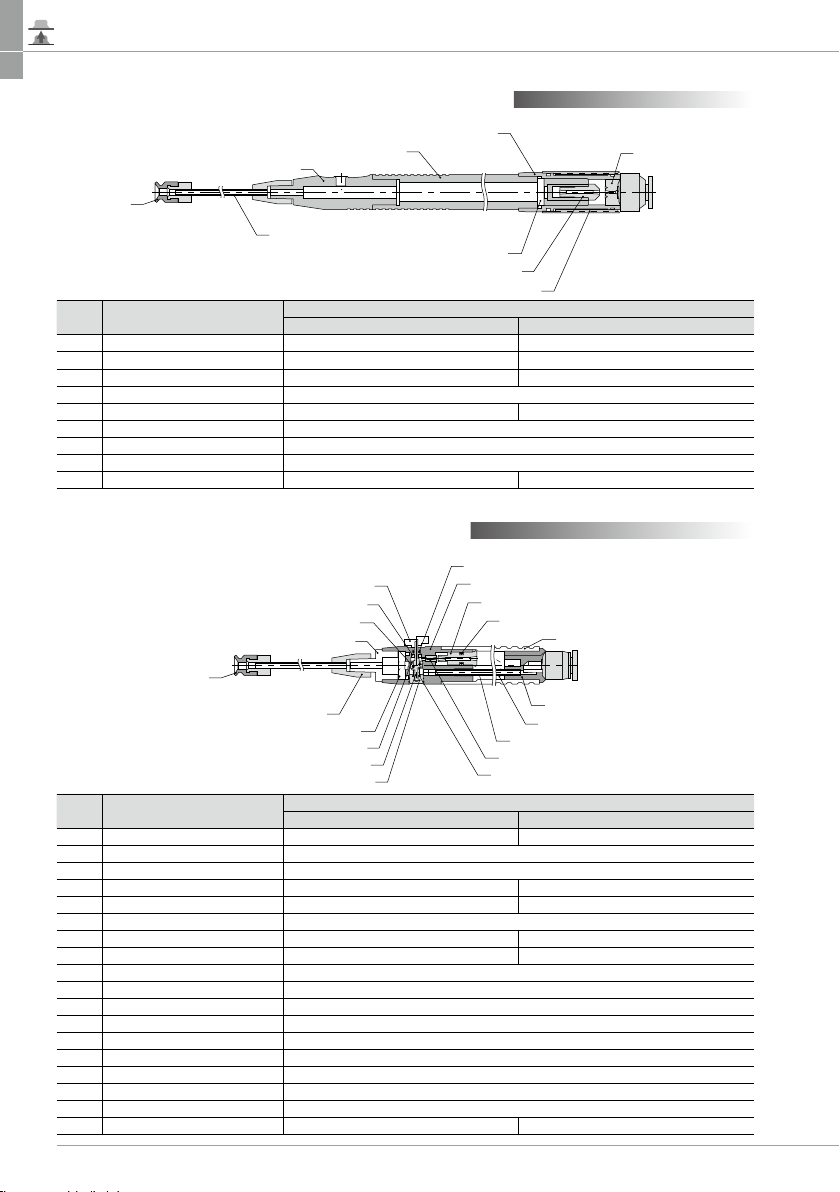

Vacuum pad holder Standard Small

Pad screw size Tightening torqueN·m

M4×0.7 0.5 ~ 1.0 0.9 ~ 1.1

M6×1 2 ~ 2.7

M10×1.5 5 ~ 7 –

M20×2 9 ~ 10 –

Pad screw size Tightening torqueN·m

M4×0.7 0.7 ~ 0.8

M6×1 1.5 ~ 2.0