Vacuum Generator VK

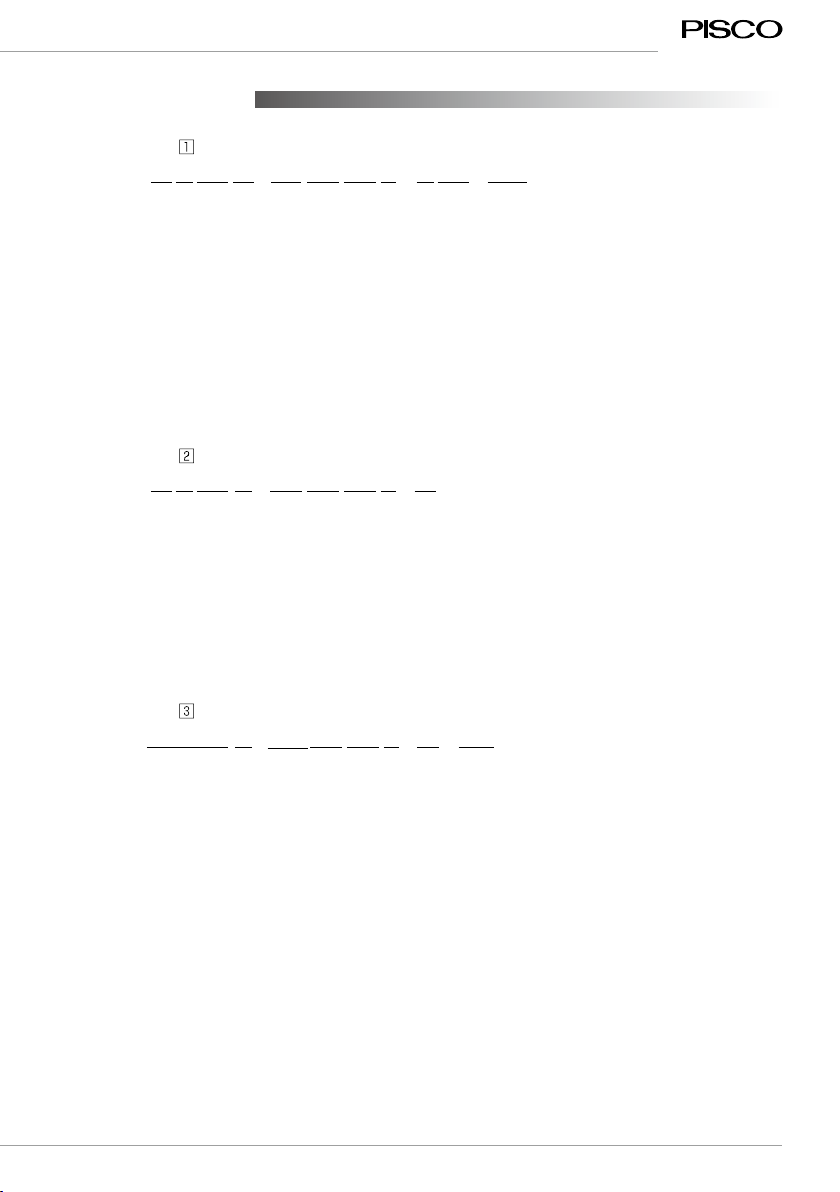

■ Model Designation (Example)

AVK 07

1/4

⑤

Vacuum port

①

Port orientation

③

Nozzle bore

H

②

Vacuum characteristics

B

⑨

Body color

① Port orientation

③ Nozzle bore. (Combinations: A, C, E, G, J, L, P, Q, R, S, T and W)

Complex Vacuum

Generator

⑩

Number of stations

‒NW

⑪

Vacuum switch

W

④

Combinations Exhaust port

⑥

Air supply port

⑧

Solenoid valve type

② Vacuum characteristics

Nozzle bore. (Combinations: B, D, F, H, K and M)

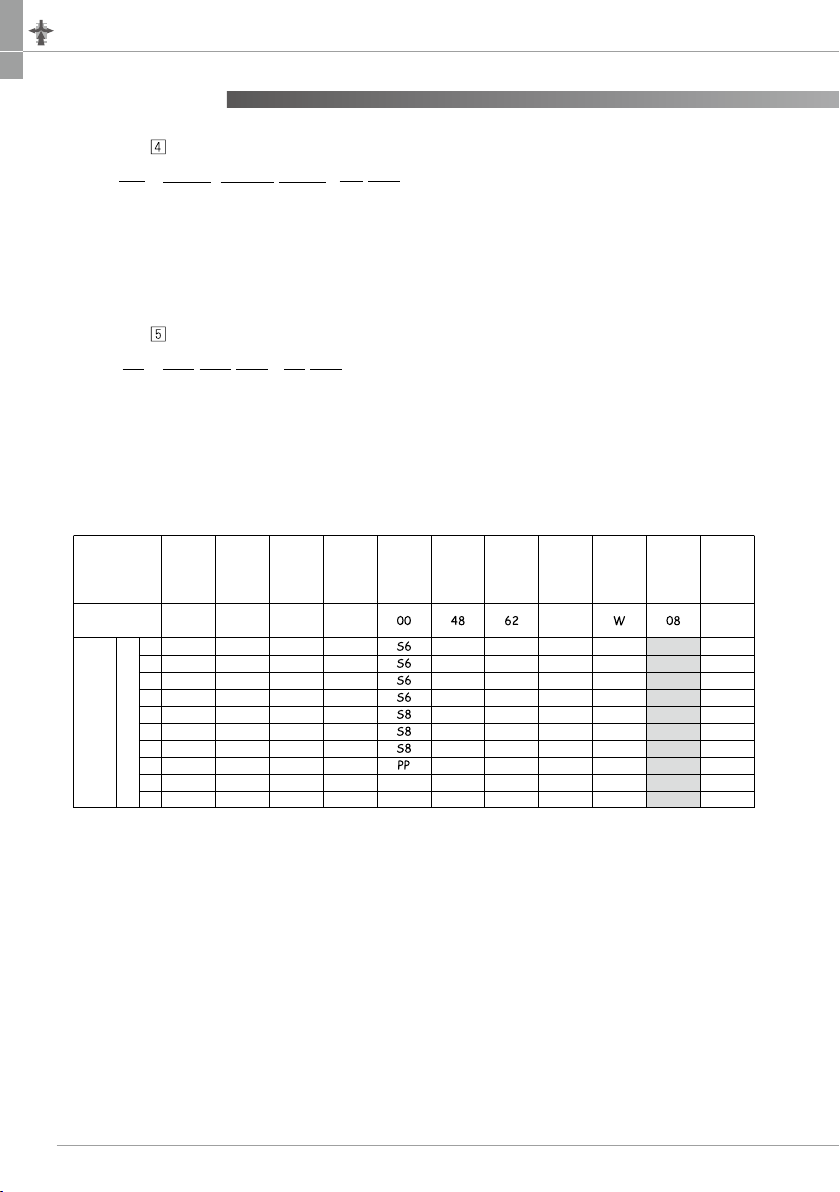

Code

A

Stand-alone type with double side port

Code

B

Stand-alone type with single side port

Code

MManifold type

Code

05

07

Nozzle

bore

0.5mm

0.7mm

H type

Vacuum level and Suction flow

(-91kPa, 7l/min[ANR] )

(-93kPa, 13l/min[ANR])

L type

Vacuum level and Suction flow

(-67kPa, 12l/min[ANR])

(-67kPa, 26l/min[ANR])

E type

Vacuum level and Suction flow

–

(-91kPa, 10.5l/min[ANR])

Air consumption

(11.5l/min[ANR])

(23l/min[ANR](17l/min[ANR]) )

Code

H

No code

Performance

High-vacuum type

Manifold-base alone

Code

L

Performance

Large-flow type

Rated supply pressure

72.5 psi (0.5MPa)

Code

E

Performance

High-vacuum at low air supply pressure type

Rated supply pressure

50 psi (0.35MPa)

Code

05

07

Nozzle

bore

0.5mm

0.7mm

H type

Vacuum level and Suction flow

L type

Vacuum level and Suction flow

E type

Vacuum level and Suction flow

–

Air consumption

(11.5l/min[ANR])

10

12

No code

1.0mm

1.2mm

(-93kPa, 27l/min[ANR])

(-93kPa, 38l/min[ANR])

(-67kPa, 40l/min[ANR])

(-67kPa, 50l/min[ANR])

(-91kPa, 21l/min[ANR])

(-91kPa, 27l/min[ANR])

(46l/min[ANR](34 l/min[ANR]) )

(70l/min[ANR](47 l/min[ANR]) )

Manifold-base alone

10

12

No code

1.0mm

1.2mm

Manifold-base alone

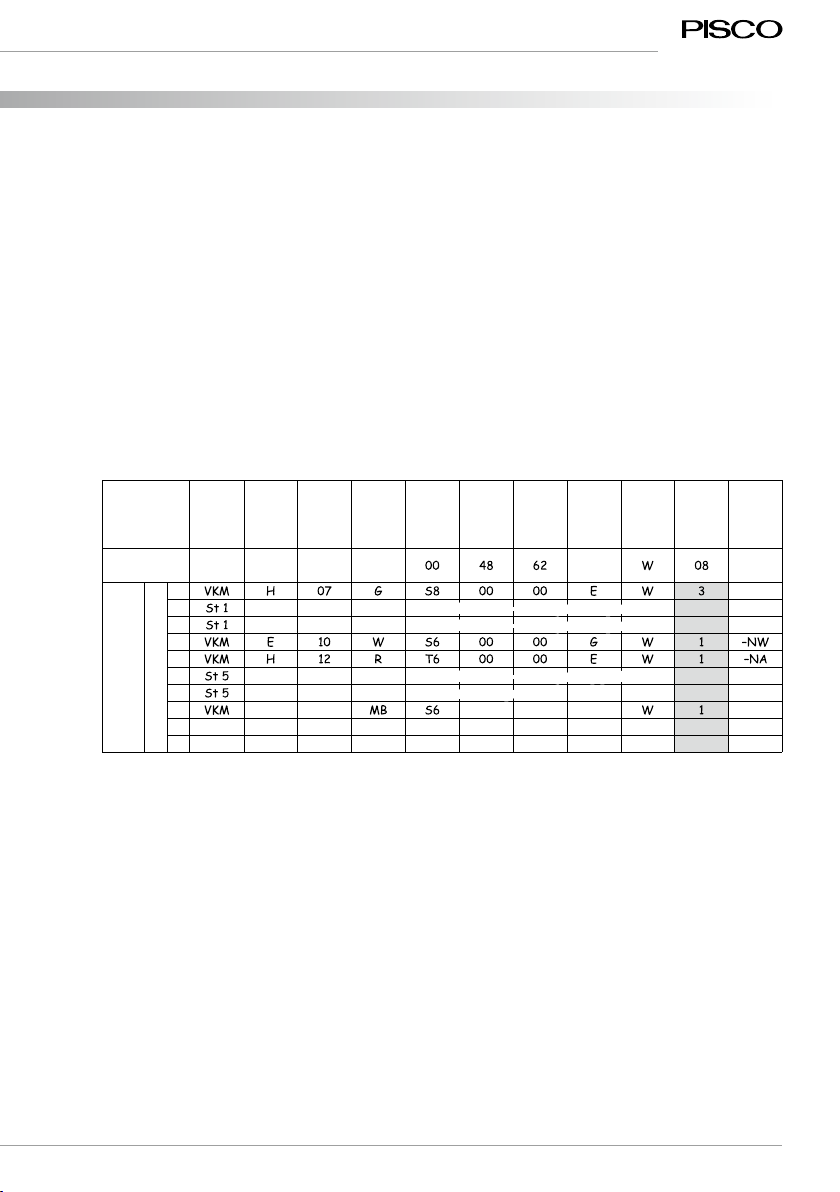

S

E

⑦

1/4

Rated supply pressure

72.5 psi (0.5MPa)

( ) ( () )

-26.8inHg, 0.25scfm -19.8inHg, 0.42scfm 0.41scfm

-27.6inHg, 0.46scfm -19.8inHg, 0.91scfm -27inHg, 0.37scfm 0.81scfm (0.60scfm)

-27.6inHg, 0.95scfm -19.8inHg, 1.40scfm -27inHg, 0.37scfm 1.63scfm (1.20scfm)

-27.6inHg, 1.33scfm -19.8inHg, 1.75scfm -27inHg, 0.95scfm 2.47scfm (1.67scfm)

※Suction flow of the vacuum port size with 5/32" O.D. and ø4mm may be different from the above values.

※Supply pressure is 72.5psi (0.5MPa)for H and L type and 50psi (0.35MPa)for E type.

※Air consumption values in ( ) represents that of E type.

※The values in the table are reference values only. Suction flow varies according to the vacuum system conditions;

vacuum port dia. or tube length.

-

25.5inHg, 0.19scfm

(-86.5kPa, 5.4l/min[ANR])

-

19.6inHg, 0.35scfm

(66.5kPa, 10l/min[ANR] )

0.41scfm

-

26.7inHg, 0.39scfm

(-

90.5kPa, 11l/min[ANR])

-

19.6inHg, 0.67scfm

(-66.5kPa, 19l/min[ANR])

-

25.5inHg, 0.30scfm

(-86.5kPa, 8.4l/min[ANR])

0.81scfm (0.60scfm)

(

23l/min[ANR](17l/min[ANR]))

-

26.7inHg, 0.67scfm

(-90.5kPa, 19l/min[ANR])

-

19.6inHg, 0.85scfm

(-66.5kPa, 24l/min[ANR])

-

25.5inHg, 0.54scfm

(-86.5kPa, 15.4l/min[ANR])

1.63scfm (1.20scfm)

(

46l/min[ANR](34l/min[ANR]))

-

26.7inHg, 0.85scfm

(-90.5kPa, 24l/min[ANR])

-

19.6inHg, 0.95scfm

(-66.5kPa, 27l/min[ANR])

2.47scfm (1.67scfm)

(

70l/min[ANR](47l/min[ANR]))

-

25.5inHg, 0.67scfm

(-86.5kPa, 19l/min[ANR])