pitsco Structures Testing Instrument User manual

59921 V0217

Structures Testing

Instrument

User Guide

2 Structures Testing Instrument User Guide 59921 V0217

The Structures Testing Instrument oers ne-tuned testing and several unit options.

Using a turn force wheel, you can apply up to 800 pounds of force to structures such as balsa wood or

basswood towers and bridges. You don’t have to destroy the structure to test it to the limit – just apply

pressure in small increments and stop applying pressure at the rst sign of structural damage. And because

the system captures both the peak load (force) and the current load (force) on the display, the load that

breaks the structure is displayed. The tester can display the force in pounds, kilograms, and newtons.

With the tester’s software, you can graph the force as a line chart per structure and print it to analyze it

later. This software also enables you to connect the computer to a projector to display testing data in the

classroom.

Note: Bridges tested should be no longer than the span column support and no wider than the structure

supports. Towers must be no taller than the 11-1/2" threaded rod and no wider than the acrylic tower shield.

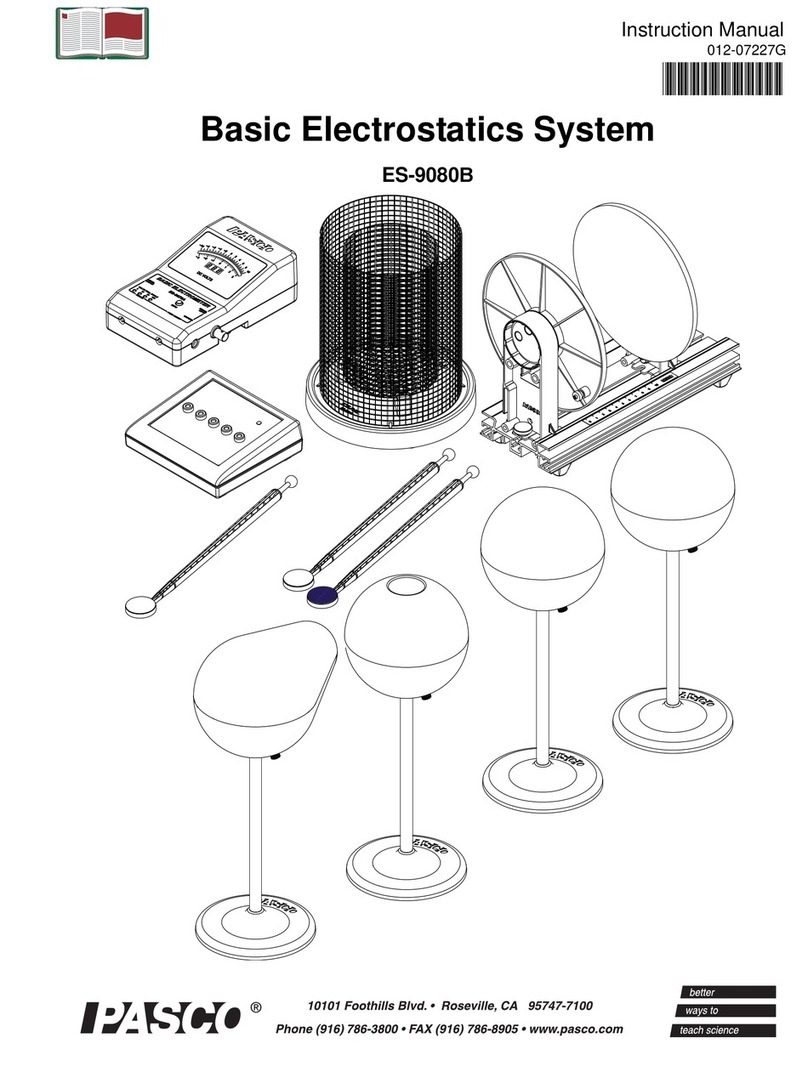

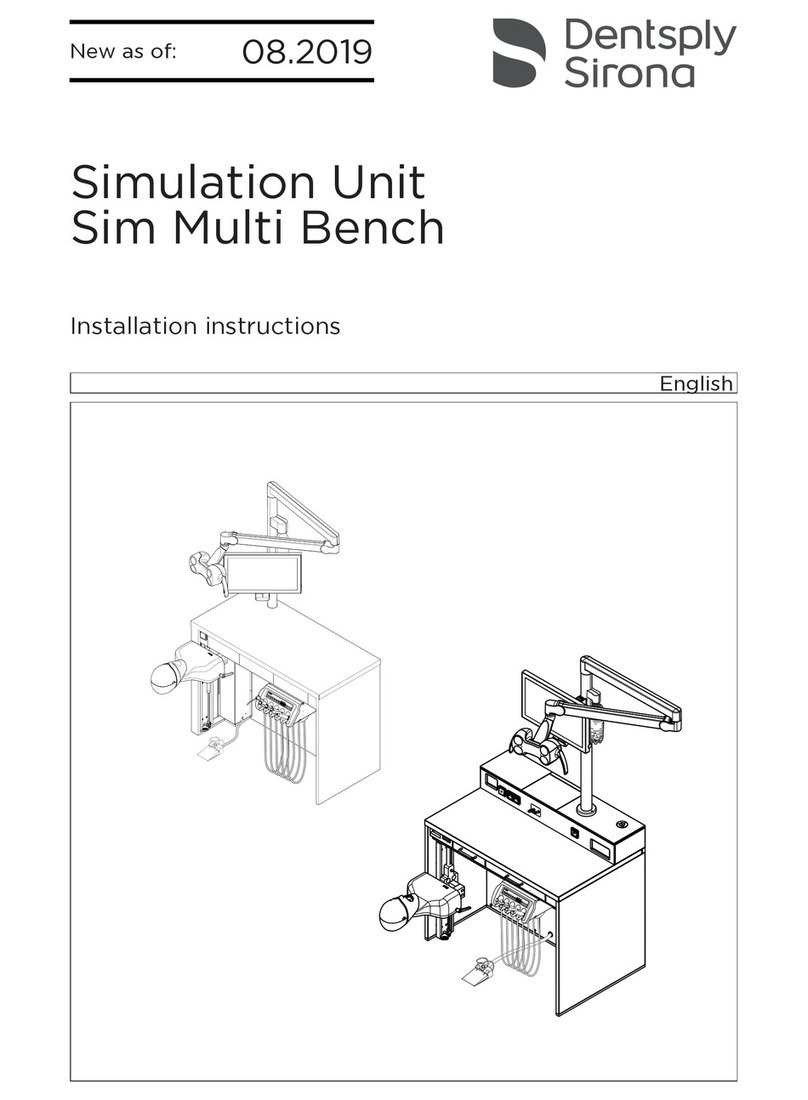

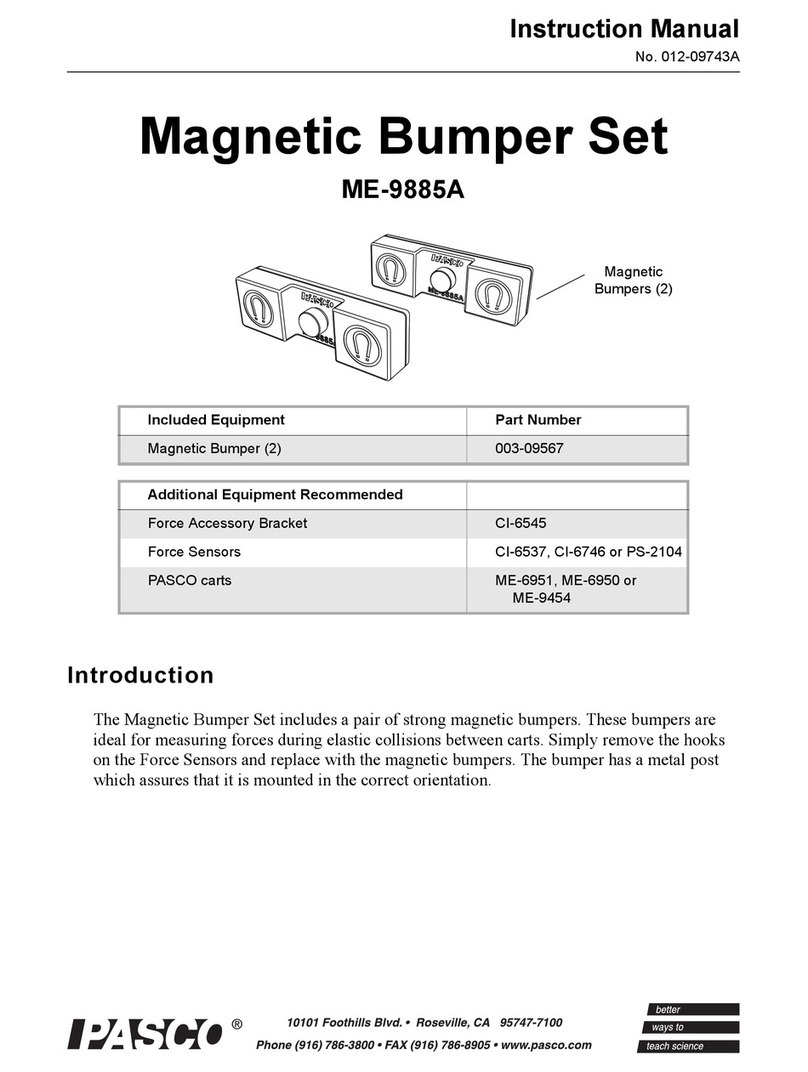

Items Included

A. Structures Testing Instrument G. USB cable

B. Acrylic tower shield H. 5-1/2" and 11-1/2" threaded rods

C. 6 roadbed load blocks (6 sizes) I. Tower load plate

D. 2 span columns J. Washer, hex nut, and wing nut

E. 2 structure supports K. Power supply

F. 2 span locking pins

A. Structures Testing Instrument

G. USB

cable

F. 2 span

locking pins

E.

2 structure

supports

D. 2 span

columns

C. 6 roadbed

load blocks

B. Acrylic

tower

shield

K. Power supply

J. Washer, hex nut, and wing nut

I. Tower

load plate

H. Threaded rods

Span column support

Structures Testing Instrument User Guide 59921 V0217 3

Materials and Tools Required (not included)

• Standard 120-volt electrical outlet

• Balsa wood or basswood structure for testing

• Safety glasses

Safety

• This kit is designed and intended for educational purposes only.

• Use only under the direct supervision of an adult who has read and understood the instructions provided

in this user guide.

• Read warnings on packaging and in manual carefully.

• Always wear safety glasses when using the tester or working within 10 feet of the tester.

• Only test balsa wood or basswood structures on the tester.

• Do not exceed 800 pounds of pressure when testing or the tester might be damaged.

• Store the tester in a dry place at room temperature.

• Do not get the tester wet.

Preparing to Test

1. Place the tester on a level, stable surface such as a sturdy desk or table. Make sure the tester is not close to

the surface’s edge.

2. Plug the tester into an electrical outlet.

3. If using the included software to record and

graph testing data, see the Using the Software

section on page 7.

Testing a Bridge

This procedure can also be used to test a truss or

similar structures. If using the software, be sure to

read the directions on page 7 before starting to

test a structure.

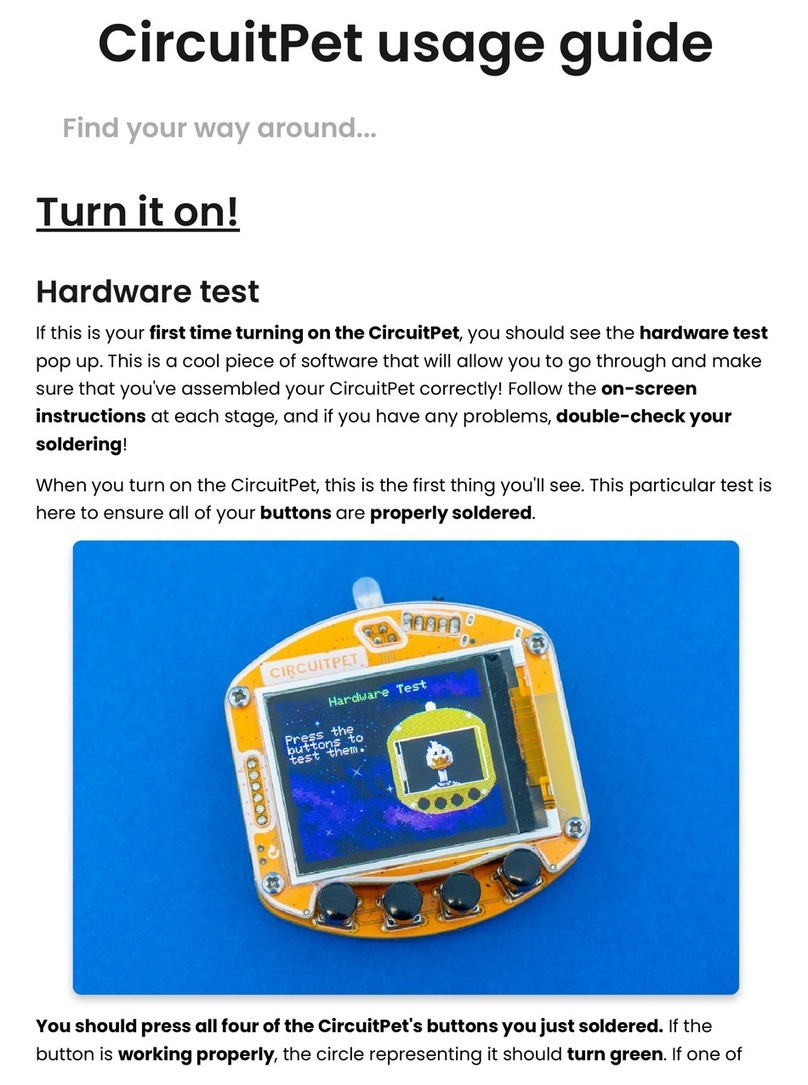

1. Place the span columns in the tester’s span

column support, one on either side of the

tester’s center (Figure 1).

2. Place the metal bracket end of each structure

support into the top of each span column

(Figure 2). Do this so that the length of

the support is perpendicular (crosswise)

to the span column support.

3. Set the bridge on top of the structure

supports. Move the supports so the

structure is centered over the middle of

the tester and each end of the bridge’s

roadbed overlaps the supports enough

to securely hold the bridge (usually a half

inch to an inch).

4. Insert the span locking pins into the span

columns to lock them in place (Figure 3).

Remove the bridge.

Figure 1

Figure 2 Figure 3

4 Structures Testing Instrument User Guide 59921 V0217

5. Find the 5-1/2" threaded rod; note how the

threads on one end have been stripped. With this

end up, screw the threaded rod into the center of

the tester until it stops (Figure 4).

6. Turn the tester’s turn force wheel clockwise

until it stops. The load cell indicator should be at

the top. Do not force the wheel any farther. Set

the bridge back on the tester between the two

structure supports.

7. Select a roadbed load block that is the closest to

being two inches shorter than the total length

of the bridge’s roadbed. Slide the block into the

bridge and on top of its roadbed; the load block

will have a hole to t over the top of the threaded

rod (Figure 5).

8. Place the at washer over the rod, followed by

either the wing nut or hex nut (the hex nut is

best for tight spaces). Tighten the nut until it is approximately 1/16" above the load block (Figure 6).

9. Above the digital display, push the Zero button.

The display will show both the force and peak

loads, indicated here by “Force Lbf” and “Peak Lbf.”

(“Lbf” means “force pound.”)

10. Select which unit of measurement you wish to

use: pound or kilogram. To do this, press the Select

button to see the options alternate on the screen.

When you see the measurement you want, press

Select. The tester will return to the force and peak

load display.

11. To apply force to the structure, slowly turn the

force wheel counterclockwise (Figure 7). Continue

to apply pressure appropriate to your testing type.

Choose from the following (on next page):

Figure 4

Figure 5 Figure 6

Figure 7

Structures Testing Instrument User Guide 59921 V0217 5

• Nondestructive test: Using the force wheel, slowly and continuously apply force to the structure

until the measured force reading begins to drop and no longer tracks the peak force. You will often

hear a slight crack or pop come from the structure when this occurs. At this point, the structure

cannot bear any more load without continuing to damage the structure. Stop applying force.

• Destructive test: Apply force until the structure is broken.

The display will ash, make an audible noise, and show “Warning Maximum Force” when maximum force

is reached.

12. If you aren’t using the downloadable software, record the force readings from the test.

13. Remove the nut, washer, load block, and bridge from the tester. Press the Zero button.

Follow Steps 6-13 to test subsequent bridges or

structures, adjusting the width of the span columns as

needed.

Testing a Tower

If using the software, be sure to read the directions on

page 7 before testing a structure.

Note: You do not need the span columns and

structure supports to test towers; however, you do

not have to remove them from the tester unless they

prevent placing the acrylic shield on the tester.

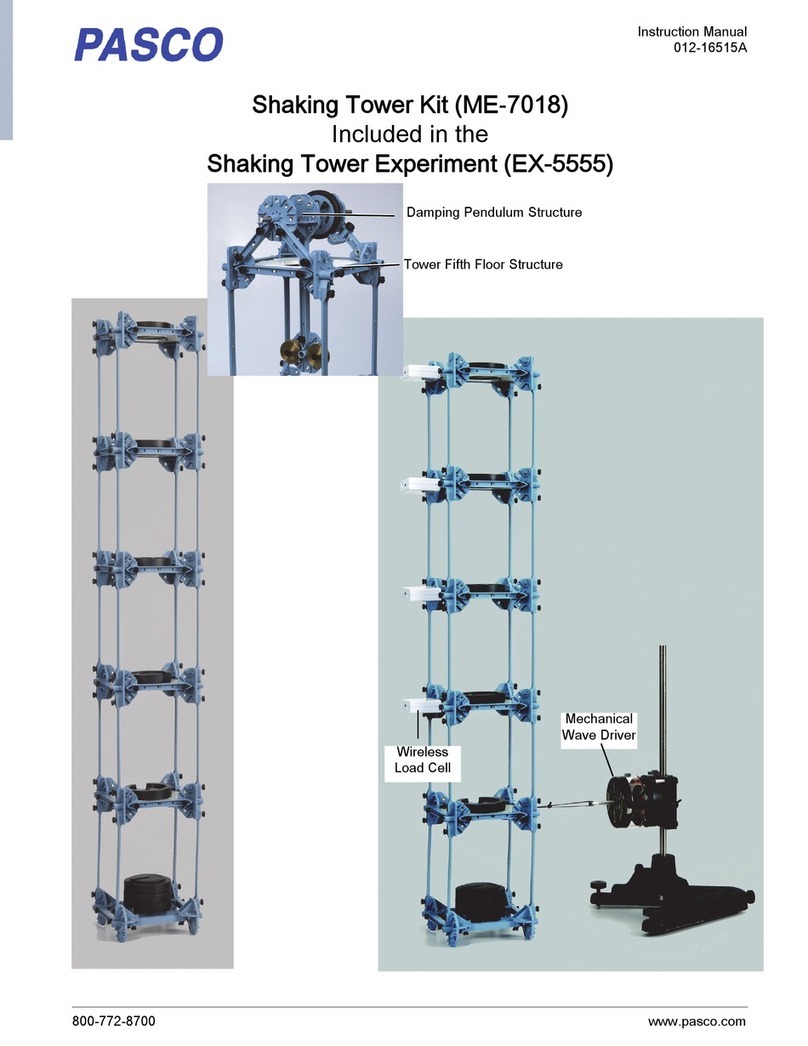

1. If the tester has the 5-1/2" threaded rod in, remove

it and replace it with the 11-1/2" rod. Be sure the

end with the stripped threads is pointing up.

2. Turn the tester’s turn force wheel clockwise until it

stops. The load cell indicator should be at the top.

Do not force the wheel any farther.

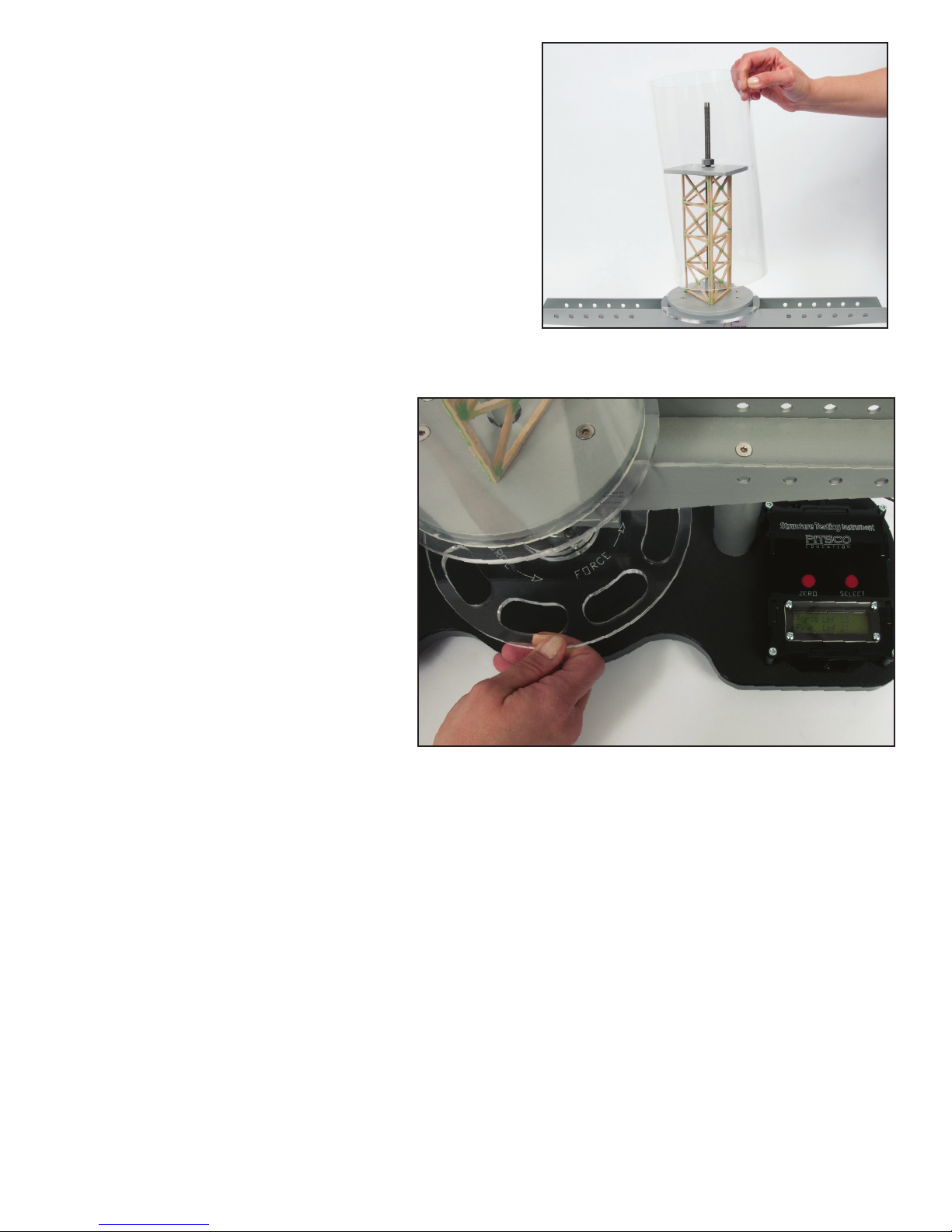

3. Place the tower over the rod (Figure 8).

4. Place the tower load plate over the threaded rod

and set it on top of the tower (Figure 9). Drop

the washer over the rod and onto the load plate

and screw the hex nut (not the wing nut) over

it, stopping approximately 1/16" above the load

plate (Figure 10).

Figure 8

Figure 9 Figure 10

6 Structures Testing Instrument User Guide 59921 V0217

5. Place the acrylic shield over the tower (Figure 11).

6. Above the digital display on the tester, push the Zero

button. The display will show both the force and peak

loads, indicated by “Force Lbf”and“Peak Lbf.”

7. Select which unit of measurement you wish to use:

pound or kilogram. To do this, press the Select button

to see the options alternate on the screen. When you

see the measurement you want, press Select again. The

tester will return to the force and peak load display.

8. To apply force to the structure, slowly turn the force

wheel counterclockwise (Figure 12). Continue to apply

pressure appropriate to your testing type. Choose from

the following:

• Nondestructive test: Using the force wheel, slowly

and continuously apply force to the

structure until the measured force

reading begins to drop and no longer

tracks the peak force. You will often

hear a slight crack or pop come from

the structure when this occurs. At

this point, the structure cannot bear

any more load without continuing to

damage the structure. Stop applying

force.

• Destructive test: Apply force until the

structure is broken.

The display will ash, make an audible

noise, and show“Warning Maximum

Force” when maximum force is reached.

9. If you aren’t using the downloadable

software, record the force readings from

the test.

10. Remove the nut, washer, load plate, and tower from

the tester. Press the Zero button.

11. Follow Steps 2-10 to test subsequent towers.

Figure 12

Figure 11

Structures Testing Instrument User Guide 59921 V0217 7

Using the Software

The tester comes with a USB cable for use with a Windows PC. The software can be found on the Structures

Testing Instrument product page under the Resources tab along with a PDF explaining how to use it.

The software is ideal for enabling the entire class to see the test data by connecting the computer to an

overhead projector or to a large monitor. To do this, follow the projector or monitor’s instructions for

connecting to your computer.

The software also creates a line chart of the test data to give students a visual reference. The chart will record

up to ve minutes, which should be plenty of time for an individual structure test. Each test’s chart and data

display can be printed.

8 Structures Testing Instrument User Guide 59921 V0217

P.O. Box 1708 • Pittsburg, KS 66762

shop.pitsco.com

Toll-Free Orders 800-835-0686

Table of contents

Other pitsco Science Education Product manuals