Indice degli argomenti

1 Norme di sicurezza ....................................................................................................................................................72

2 Identificazione di modello.......................................................................................................................................72

3 Dati tecnici...................................................................................................................................................................72

3.1 Caratteristiche generali ............................................................................................................................72

3.2 Caratteristiche Hardware.........................................................................................................................73

3.3 Caratteristiche software...........................................................................................................................73

4 Dimensioni e installazione ...................................................................................................................................... 74

5 Collegamenti elettrici................................................................................................................................................ 74

5.1 Schema di collegamento.......................................................................................................................... 75

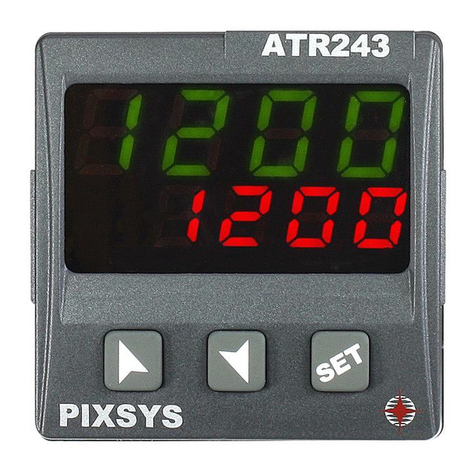

6 Funzione dei visualizzatori e tasti..........................................................................................................................79

6.1 Indicatori numerici (display)....................................................................................................................79

6.2 Significato delle spie di stato (Led).........................................................................................................79

6.3 Tasti................................................................................................................................................................79

7 Modalità doppio ingresso........................................................................................................................................80

7.1 Selezione grandezza correlata al comando e agli allarmi ..............................................................80

7.2 Setpoint remoto da ingresso analogico ...............................................................................................80

7.3 Setpoint remoto da ingresso seriale ...................................................................................................... 81

8 Funzioni del regolatore.............................................................................................................................................81

8.1 Modifica valore setpoint principale e di allarme................................................................................ 81

8.2 Tuning automatico .................................................................................................................................... 81

8.3 Tuning manuale ......................................................................................................................................... 81

8.4 Tuning once .................................................................................................................................................82

8.5 Tuning sincronizzato.................................................................................................................................82

8.6 Funzioni da Ingresso digitale ..................................................................................................................82

8.7 Regolazione automatico / manuale del controllo % uscita ............................................................83

8.8 Heater Break Alarm su CT (Trasformatore Amperometrico - solo ATR244-23xx-T)....................84

8.9 Funzionamento in doppia azione (caldo-freddo)..............................................................................84

8.10 Funzione LATCH ON...................................................................................................................................85

8.11 Funzione Soft-Start ....................................................................................................................................86

8.12 Funzione ritrasmissione su uscita analogica.......................................................................................86

9 Comunicazione Seriale.............................................................................................................................................86

10 Lettura e configurazione via NFC........................................................................................................................... 91

11 Accesso alla configurazione....................................................................................................................................92

11.1 Caricamento valori di default .................................................................................................................93

11.2 Funzionamento della lista parametri....................................................................................................93

12 Tabella parametri di configurazione.....................................................................................................................93

13 Modi d’intervento allarme.....................................................................................................................................129

14 Tabella segnalazioni anomalie ............................................................................................................................ 131

Index des sujets

1 Règles de sécurité.....................................................................................................................................................139

2 Identification du modèle........................................................................................................................................139

3 Données techniques................................................................................................................................................139

3.1 Caractéristiques générales.....................................................................................................................139

3.2 Caractéristiques Hardware ....................................................................................................................140

3.3 Caractéristiques Software......................................................................................................................140

4 Dimensions et Installation..................................................................................................................................... 141

5 Raccordements électriques ................................................................................................................................... 141

5.1 Plan des connexions ................................................................................................................................142