4 - ATR227 - Manuale d’uso

Sommario

1 Norme di sicurezza .................................................................................................................................... 25

2 Identicazione del modello..................................................................................................................... 25

3 Dati tecnici ................................................................................................................................................... 25

3.1 Caratteristiche generali .................................................................................................................. 25

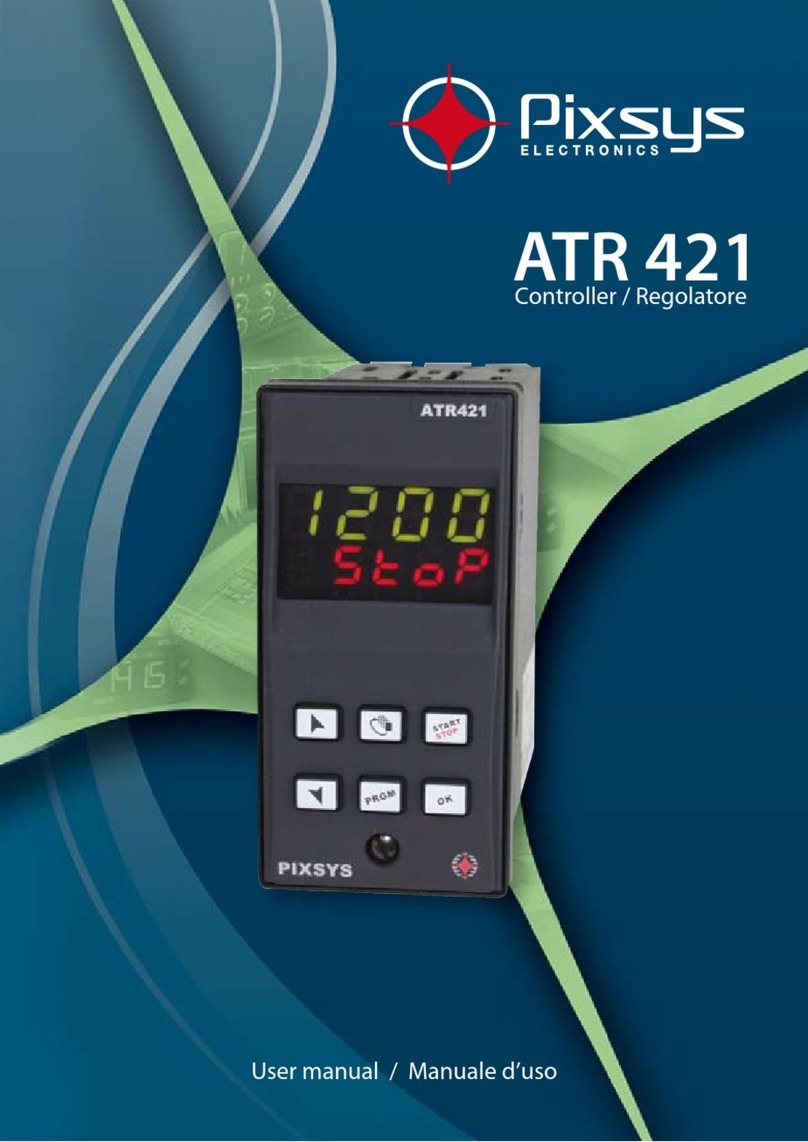

3.2 Caratteristiche Hardware............................................................................................................... 26

3.3 Caratteristiche Software ................................................................................................................ 26

4 Dimensioni ed installazione.................................................................................................................... 27

5 Collegamenti elettrici................................................................................................................................27

5.1 Schema di collegamento................................................................................................................ 28

6 Funzione dei visualizzatori e tasti.......................................................................................................... 29

6.1 Indicatori numerici (Display) ........................................................................................................ 30

6.2 Signicato delle spie di stato (Led) .............................................................................................. 30

6.3 Tasti ...................................................................................................................................................... 30

7 Funzioni del regolatore .............................................................................................................................31

7.1 Modica valore setpoint principale e setpoint di allarme......................................................31

7.2 Auto-Tuning .......................................................................................................................................31

7.3 Lancio del Tuning Manuale ............................................................................................................31

7.4 Lancio del Tuning Automatico.......................................................................................................31

7.5 Soft-Start..............................................................................................................................................31

7.6 Regolazione automatico / manuale per controllo % uscita................................................. 32

7.7 Funzioni da Ingresso digitale ........................................................................................................ 32

8 Accesso alla congurazione.................................................................................................................... 33

8.1 Caricamento valori di default ....................................................................................................... 33

9 Tabella parametri di congurazione .................................................................................................... 34

10 Modi d’intervento allarme....................................................................................................................... 40

11 Tabella segnalazioni anomalie.............................................................................................................. 43

12 Congurazione EASY-UP.......................................................................................................................... 43

13 Promemoria congurazione................................................................................................................... 44